High Integration and Rapid Response: Superior Performance of Modern Electric Fire Pump Controls

The electric fire pump control system features intelligent control, high energy efficiency, and multiple safety protections, ensuring rapid response and stable operation of the fire water supply system in emergency situations. Utilizing advanced PLC control and a highly efficient motor drive, it supports automatic start/stop and remote monitoring. Suitable for high-rise buildings, industrial plants, and municipal fire protection projects, it provides reliable power for modern fire protection systems.

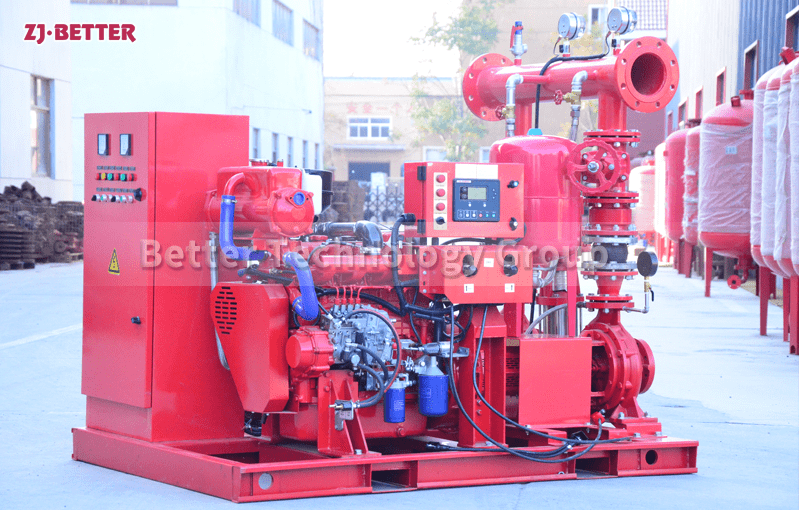

In modern building fire protection systems, electric fire pump control systems, as a core component, bear the crucial responsibility of ensuring stable water supply pressure, enabling intelligent control, and improving emergency response speed. With the acceleration of urbanization and the rise of building safety standards, the automation and intelligence level of fire protection systems has become a key indicator of building fire safety capabilities, and electric fire pump control systems are a key component supporting the efficient operation of this system. This system not only features a sophisticated technical design but also incorporates advanced automatic control concepts and high-performance components, resulting in superior performance in terms of stability, responsiveness, and safety protection. An electric fire pump control system typically consists of an electric motor-driven main pump, a control cabinet, a piping system, and automatic detection components. Its design focuses on high reliability and low maintenance. The control cabinet integrates an intelligent control module, pressure sensors, current monitoring devices, an alarm system, and multiple protection circuits. It monitors pipe network pressure and operating status in real time and automatically starts and stops the pumps according to predefined parameters, ensuring a stable fire water supply under all conditions. Its highly integrated design effectively reduces the signal delays often seen in traditional systems, enabling rapid activation at critical moments during a fire, ensuring timely delivery of firefighting water to the sprinkler system or fire hydrants, thus buying valuable time for rescue efforts. In terms of performance, the electric fire pump control system utilizes a high-efficiency motor drive, delivering powerful power within a short period of time, ensuring continuous operation of the pump under high pressure without excessive energy loss. The motor and pump are connected via a precision coupling, resulting in a compact design and smooth transmission, significantly improving the efficiency of mechanical energy transfer. The pump body is constructed of corrosion-resistant, high-strength materials, suitable for a variety of water supply media, and maintains stable flow output and low vibration and noise over extended operation. Furthermore, the system features an automatic switching function that detects power supply anomalies and automatically initiates protective actions to prevent motor overload or short circuits, extending equipment life and mitigating potential electrical hazards. A key technical highlight of this control system is its intelligent operational logic. While traditional fire pump systems typically rely on manual activation or single pressure switch control, modern electric fire pump control systems utilize a PLC intelligent controller to implement a multi-level response mechanism. It automatically determines its operating mode based on pipeline pressure, flow rate fluctuations, water demand, and fire alarm signals, providing a closed-loop control mechanism: automatic pump start, stable water supply, and automatic pump stop. Upon detecting a drop in pipeline pressure to a preset value, the system immediately issues a start signal, instantly activating the motor and driving the pump. Once the fire alarm is lifted or pressure is restored, the system automatically delays shutdown, preventing wear and tear on the equipment caused by frequent starts and stops. This comprehensive logic control system not only improves equipment reliability but also reduces operational errors caused by human intervention, enabling truly unattended operation. Safety is also a core advantage of the system. The control cabinet is equipped with an electrical protection module, including multiple safety mechanisms such as overload protection, undervoltage protection, phase loss protection, short-circuit protection, and temperature alarms. These modules instantly cut off power and sound an alarm in any abnormal condition, ensuring the safety of the system and personnel. The system also interfaces with the fire alarm center. Upon receiving a fire signal, the pumps automatically start and operate without human intervention, enabling both remote and local control. To accommodate the needs of buildings and projects of varying sizes, the system supports parallel operation of multiple pumps. Through an intelligent switching program, it automatically schedules primary and backup pumps, ensuring continuous fire water supply and balancing the service life of each pump during non-emergency situations. The electric fire pump control system also excels in energy efficiency management. The combination of a highly efficient energy-saving motor and variable frequency control technology enables it to automatically adjust operating speed based on actual water consumption, significantly reducing energy consumption. Variable frequency operation not only reduces current surges but also effectively reduces system noise, improving overall operational stability. For long-term building fire protection systems, this energy-saving feature reduces operating costs while extending equipment maintenance cycles, further improving return on investment. The system also features a comprehensive human-machine interface with a digital display and touch-screen operation, allowing users to intuitively view operating data, alarm logs, pressure trends, and pump status, enabling real-time monitoring and remote management. Select models even support IoT communication, enabling equipment status diagnosis, data analysis, and maintenance reminders via a cloud platform, providing strong technical support for the smart fire protection system. This information-based management model not only enhances the visibility of firefighting equipment but also makes maintenance more efficient and effective. The electric fire pump control system adopts a modular layout for easier installation and maintenance. Its shock-resistant base effectively absorbs mechanical vibrations generated during operation, ensuring overall system stability. The control cabinet enclosure features a dust- and waterproof construction, making it suitable for a variety of complex environments, ensuring long-term reliable operation in locations ranging from underground machine rooms to industrial plants and high-rise buildings. The internal electrical wiring is standardized and organized, and all connection ports are protected against loosening and moisture, further enhancing system durability. Furthermore, the system supports manual and automatic mode switching, allowing users to flexibly select the operating mode based on different application scenarios, ensuring stable water supply even under challenging circumstances. Another key feature of the system is its wide range of applications. Whether in high-rise residential buildings, commercial complexes, industrial plants, airports and terminals, or municipal water supply and emergency firefighting projects, the electric fire pump control system provides reliable operation. Its outstanding performance makes it an ideal power source for dry and wet sprinkler systems, fire hydrant systems, and foam fire extinguishing systems. Especially in emergency scenarios where reliability and responsiveness are paramount, the system’s precise control and robust water supply ensure smooth firefighting operations. The system was designed with ease of maintenance and overhaul in mind. All key components utilize standardized modular designs, facilitating rapid replacement and upgrades. The control system provides multi-level fault alarms and recording capabilities. When abnormal operating conditions are detected, it automatically alerts maintenance personnel to initiate repairs, effectively minimizing downtime. For long-term projects, this high maintainability significantly reduces ongoing operational costs. Overall, modern electric fire pump control systems offer significant advantages in performance, intelligence, safety, energy efficiency, and adaptability. They are not only the core power unit of fire protection systems but also a crucial bridge to achieving automated and intelligent fire protection. By combining advanced control technology with a reliable mechanical structure, the system ensures rapid response and continuous, stable operation of the water supply system during fire emergencies, providing a solid safety guarantee for various buildings and facilities. From its professional system design, reliable operation, and forward-looking intelligent control, the electric fire pump control system represents the future direction of modern fire protection equipment development and holds a promising future for its application in future fire protection projects.