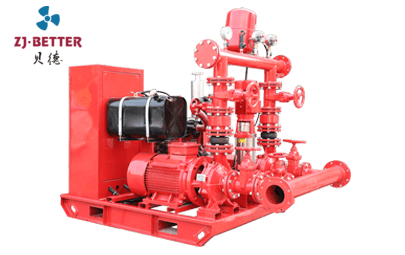

Product Features and Performance Analysis of Simplified-Structure Diesel Engine Fire Pumps

This article analyzes the features and performance of a simplified diesel engine fire pump, highlighting its compact design, stable power output, reliable hydraulic performance, and convenient maintenance advantages. It is suitable for small fire protection systems, decentralized fire protection needs, and emergency fire water supply scenarios.

Among various fire-fighting water supply equipment, the simplified diesel engine fire pump occupies an important position in small and decentralized fire-fighting systems due to its compact design, reliable performance, and strong adaptability. This type of diesel engine fire pump focuses on meeting basic fire-fighting needs. During the design phase, it fully considers the comprehensive requirements of installation convenience, operational stability, and maintenance efficiency in the actual use environment. By reducing unnecessary structural complexity, the equipment is more practical and efficient while ensuring key performance. Firstly, from an overall structural perspective, the simplified diesel engine fire pump highly integrates the diesel power unit with the fire pump body, adopting a direct-drive or short-drive structure to reduce the number of intermediate transmission components, thereby reducing mechanical losses and the risk of failure. This simple mechanical structure not only improves operational reliability but also makes the equipment smoother during startup and operation, facilitating rapid deployment in emergencies. Regarding the power system, the diesel drive itself has the advantage of independent power supply. Even when mains power is unavailable or temporary water supply points lack a stable power source, the diesel engine fire pump can still rely on its own power to start and continue operating, providing crucial support for fire-fighting water supply. Simplified structure does not equate to reduced performance. On the contrary, this type of diesel engine fire pump prioritizes a balance between efficiency and practicality in power matching. Through proper selection, the engine output power is highly matched to the hydraulic requirements of the fire pump, ensuring a stable output of the required flow and pressure under common firefighting conditions, avoiding performance fluctuations caused by power redundancy or insufficiency. Pump performance is a crucial indicator of a fire pump’s practical value. The simplified diesel engine fire pump emphasizes versatility and stability in its hydraulic design, employing mature and reliable impeller structures and flow channel forms. This allows the equipment to maintain stable water intake and delivery capabilities under various water source conditions, making it particularly suitable for diverse water intake environments such as pools, storage tanks, rivers, or temporary water sources. During operation, the smooth water flow inside the pump body and stable pressure output help quickly establish effective water pressure in basic firefighting water supply scenarios, meeting initial firefighting needs. In terms of materials and manufacturing processes, this type of diesel engine fire pump uses wear-resistant and durable metal materials for key pressure-bearing and moving parts, ensuring that the equipment maintains good performance even after long-term use or repeated start-ups. The simplified structure also makes the assembly between components more direct, which helps reduce assembly errors and improves overall durability. In terms of control and operation, the simplified design concept also demonstrates significant advantages. The equipment typically adopts an intuitive and easy-to-understand operating method; starting, stopping, and basic status checks can all be completed through simple operations, reducing reliance on professional operators. This makes it particularly suitable for locations with relatively limited operating conditions, such as rural areas, small factories, and temporary construction sites. Due to the relatively simple system structure, the equipment is also more convenient for daily inspection and maintenance. Users can quickly complete routine maintenance tasks, such as replacing vulnerable parts and checking lubrication, thus keeping the equipment in good standby condition for a long time. In terms of operational stability, the simplified diesel engine fire pump, by reducing complex accessories and control links, makes it easier for the whole machine to achieve stable performance in terms of vibration control and thermal management, maintaining reliable output under both continuous and intermittent operation conditions. For small-scale fire protection systems, this stability is particularly important because equipment often needs to function rapidly in critical moments. A simpler structure means fewer potential points of failure and higher reliability. In terms of application, this type of diesel engine fire pump is widely used in basic fire protection systems in small factories, warehouses, agricultural production areas, construction sites, and remote areas. These scenarios prioritize practicality and flexibility over complex system integration, and the simplified diesel engine fire pump perfectly meets these needs. Its relatively compact size facilitates transportation and on-site deployment, allowing for rapid deployment when temporary or backup fire water supply is required. Overall, the simplified diesel engine fire pump achieves a balance between stable performance and ease of use through reasonable optimization in structural design, power matching, hydraulic performance, and operation and maintenance. This not only lowers the barriers to use and maintenance but also enhances the reliability and practical value of the equipment in actual fire protection applications, making it a reliable and important equipment choice for basic fire water supply and small-scale fire protection systems.