The electric fire pump set is deeply loved by the public

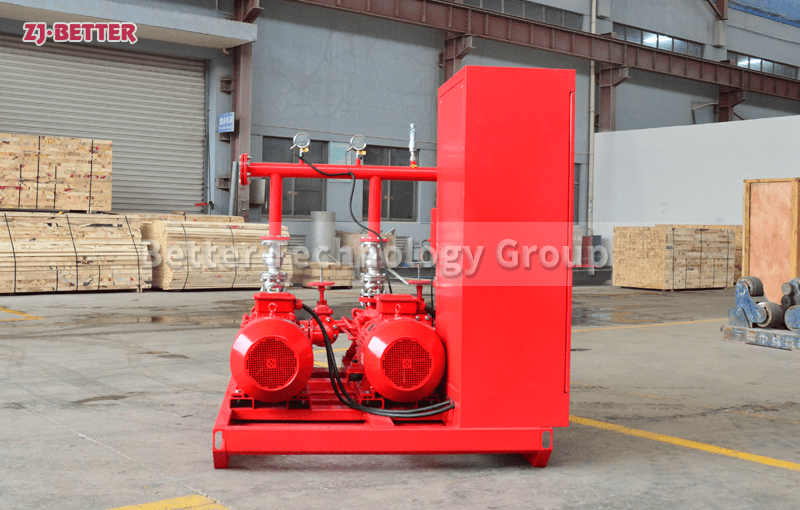

The electric fire pump can supply fire water supply in general occasions. It has complete performance and a wide range of models. It can use single-stage single-suction pumps, multi-stage single-suction pumps, self-priming pumps, long-axis pumps and other pumps, and can also be combined in parallel. Wide range of flow and pressure. Electric fire pumps are widely used in fire water supply in warehouses, docks, airports, petrochemical, power plants and other industrial and mining enterprises. Larger flow and head. The temperature of the conveying medium can reach 80°C.

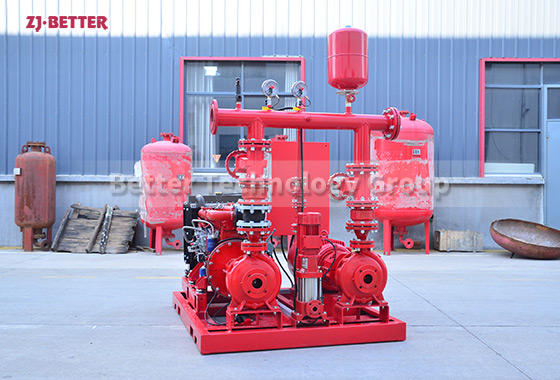

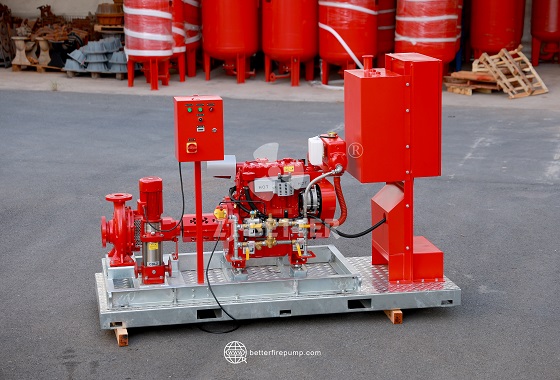

The fire water supply system is mainly composed of fire monitoring center, electric fire pump group, diesel engine fire pump group, intelligent diesel engine control panel, various instruments and meters, various valve pipes and fire water supply pipe network. , the basic linkage work process is: the diesel engine fire pump set is mainly used as the backup pump set of the electric fire pump set in the whole fire water supply system. Stabilized water supply, when a fire fire accident occurs, the pump start signal from the outside or the start and stop signal of the fire center controls the work of the electric pump unit, and the operating status of the electric pump unit is sent back to the fire center. The electric pump set will give a starting signal to the diesel engine control system (the diesel engine can also be started and stopped through the fire center) when the electric pump set is started or in the process of working if there is a failure or power failure. After the diesel engine is started, the running signal will be fed back to the fire monitoring center.