From Pump Body to System Integration: Strategic Matching of Split Case Fire Pumps in High-Flow Demand Environments

Discover the efficiency and system integration benefits of split case fire pumps in high-flow fire protection scenarios. This article highlights advanced hydraulic design, stability, intelligent control, and easy maintenance—ideal for skyscrapers, petrochemical sites, and data centers.

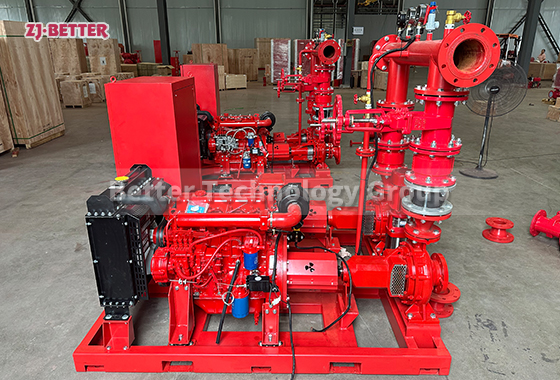

In today’s modern infrastructure, fire safety has evolved into a mission-critical concern. As high-rise buildings, large logistics warehouses, petrochemical complexes, and airport terminals continue to proliferate, the requirements for water flow, pressure stability, and rapid response within fire protection systems are becoming increasingly stringent. To meet these rigorous demands, the split case fire pump has emerged as the ideal high-capacity solution, widely adopted across complex high-flow applications.

The split case pump’s outstanding performance in large-flow systems lies in its symmetrical hydraulic design. By allowing water intake from both sides of the impeller simultaneously, the pump achieves smoother flow distribution and significantly reduces axial thrust. This not only enhances operational stability but also extends the service life of the entire pumping unit. The symmetrical pump casing improves mechanical robustness and optimizes the fluid path, leading to reduced energy consumption and improved water delivery efficiency.

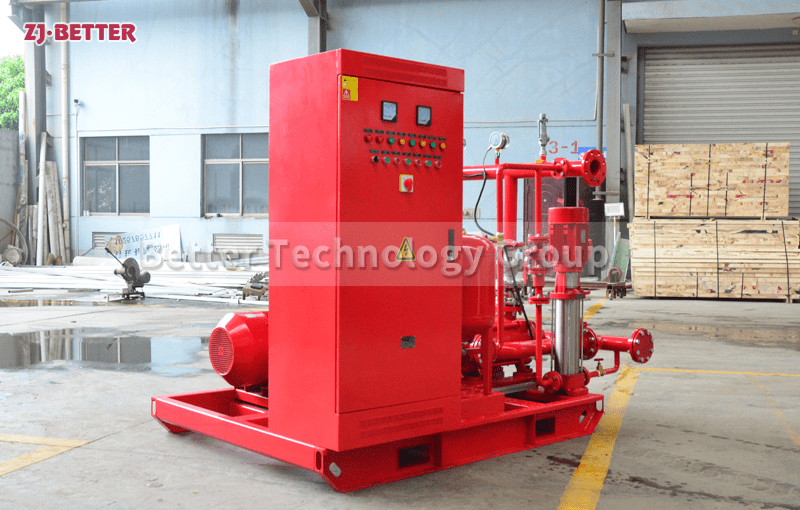

Accurate pump-to-system matching is essential for optimal performance. During the initial design phase, engineers assess critical factors such as building layout, elevation differences, and piping resistance to select the most suitable split case pump model. These pumps typically offer wide flow ranges and appropriate head characteristics. When integrated with intelligent control components—such as variable frequency drives and pressure sensors—the system can deliver water on demand and maintain constant pressure, thereby enhancing operational efficiency and reducing energy costs.

In practical deployment, split case fire pumps are commonly found in urban complexes, high-speed rail stations, petrochemical facilities, shopping malls, and data centers—any environment where uninterrupted, stable water supply is paramount. In case of fire, these pumps must activate within seconds, delivering a powerful and stable water flow. With features like high capacity, energy efficiency, low noise, and vibration resistance, split case pumps consistently ensure that fire suppression systems respond promptly and effectively.

Another advantage of this pump lies in its ease of maintenance. Thanks to its horizontal split casing, technicians can inspect or replace internal rotating components without disassembling the pipeline or motor, significantly improving maintenance efficiency and reducing operational downtime.

In summary, the split case fire pump represents more than just an advanced pumping technology; it embodies a comprehensive strategy of precise component-to-system alignment. By improving hydraulic performance and system reliability, it provides robust protection for high-demand buildings and infrastructure, ensuring fire safety with precision and confidence.

.jpg)