Merging Smart Control with Mechanical Power: Technical Analysis of Diesel Fire Pump Control Systems

The core technology and intelligent control principle of the diesel engine fire pump set control system demonstrate its application advantages and system integration capability in industrial and high-risk scenarios. Through automatic start, self-test, remote monitoring and other intelligent functions, it realizes efficient response and full protection, and is the key equipment of intelligent fire fighting system in modern buildings and industrial places.

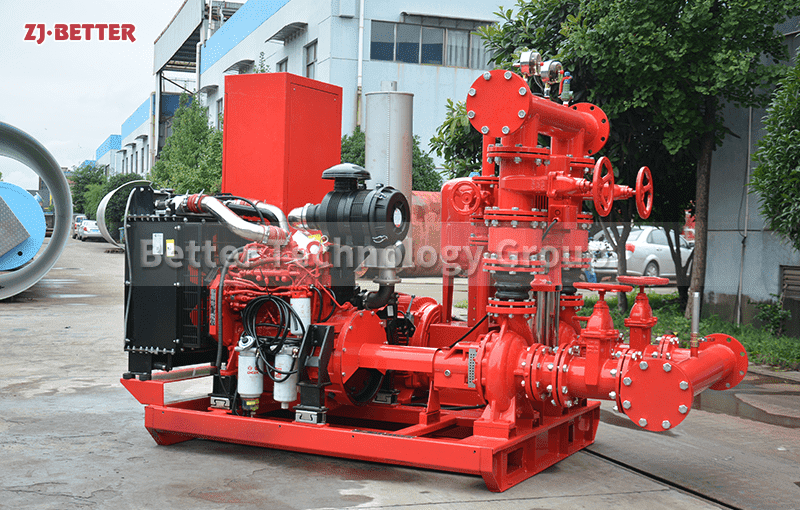

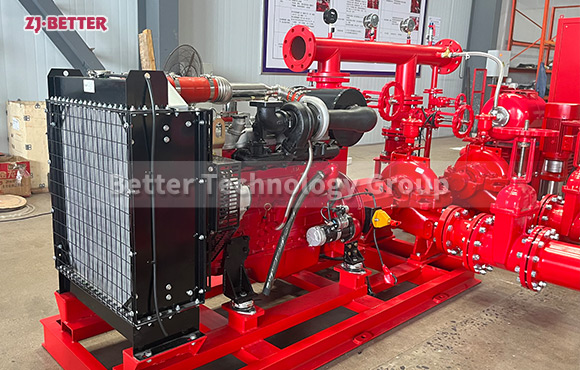

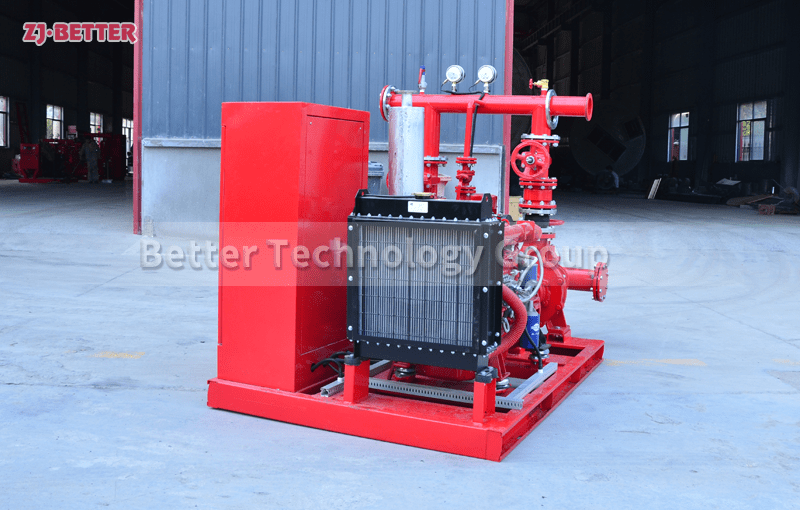

Diesel engine fire pump sets play a vital role in modern fire protection infrastructure, especially in high-risk environments such as industrial parks, logistics warehouses, petrochemical facilities, and power plants. These pump units are widely recognized for their independence from power grids, rapid start-up capabilities, and operational reliability. Among their components, the control system is the brain of the operation — it determines how effectively and safely the system can respond in critical situations. This article offers an in-depth technical analysis of diesel fire pump control systems, revealing how smart controls are seamlessly integrated with mechanical power.

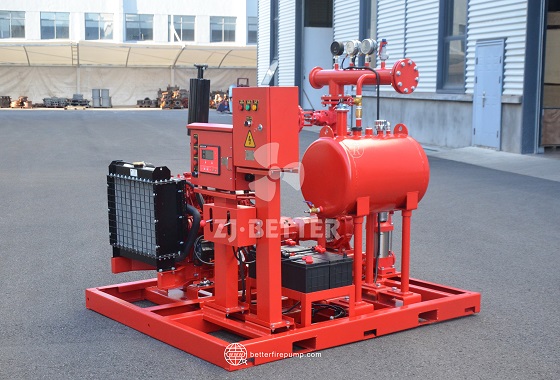

Modern diesel fire pump systems are typically equipped with intelligent electric control cabinets, centered around PLCs or microprocessor-based controllers. These modules are designed to perform multiple functions including auto-detection, auto-start, fault alarm, data logging, and remote communication. Upon receiving a fire alarm signal or detecting abnormal water pressure, the system can autonomously activate the diesel pump within seconds to ensure immediate firefighting response.

Control systems are equipped with multiple startup modes (manual/auto/remote), self-diagnosis protocols, and scheduled inspection functions to guarantee long-term standby readiness. Internally, the control cabinet utilizes high-reliability components from industry-leading brands such as ABB, Schneider, or Siemens. These parts ensure resistance to electrical interference, heat, dust, and harsh operating conditions. The user interface is intuitive, featuring a digital LCD panel that displays real-time operating data such as engine RPM, oil pressure, water temperature, and battery voltage. It also records runtime hours and fault logs to facilitate regular maintenance.

Beyond standalone operation, the diesel fire pump control system can interface with building automation systems and fire alarm networks through RS485 communication ports and Modbus protocols. For high-end models, IoT capabilities allow for cloud-based remote monitoring, real-time alerts, remote startup, and data archiving — all contributing to smarter and faster system management.

In summary, diesel engine fire pump control systems are not just mechanical-electrical hybrids; they represent the convergence of intelligent automation, operational safety, and technical robustness. Their continuous innovation drives the evolution of fire safety systems toward higher reliability and smarter performance, making them an indispensable asset in modern industrial and commercial fire protection strategies.