Precision-Fit for Complex Systems: Application Trends of Horizontal Electric Multistage Pumps in Super High-Rise Fire Protection

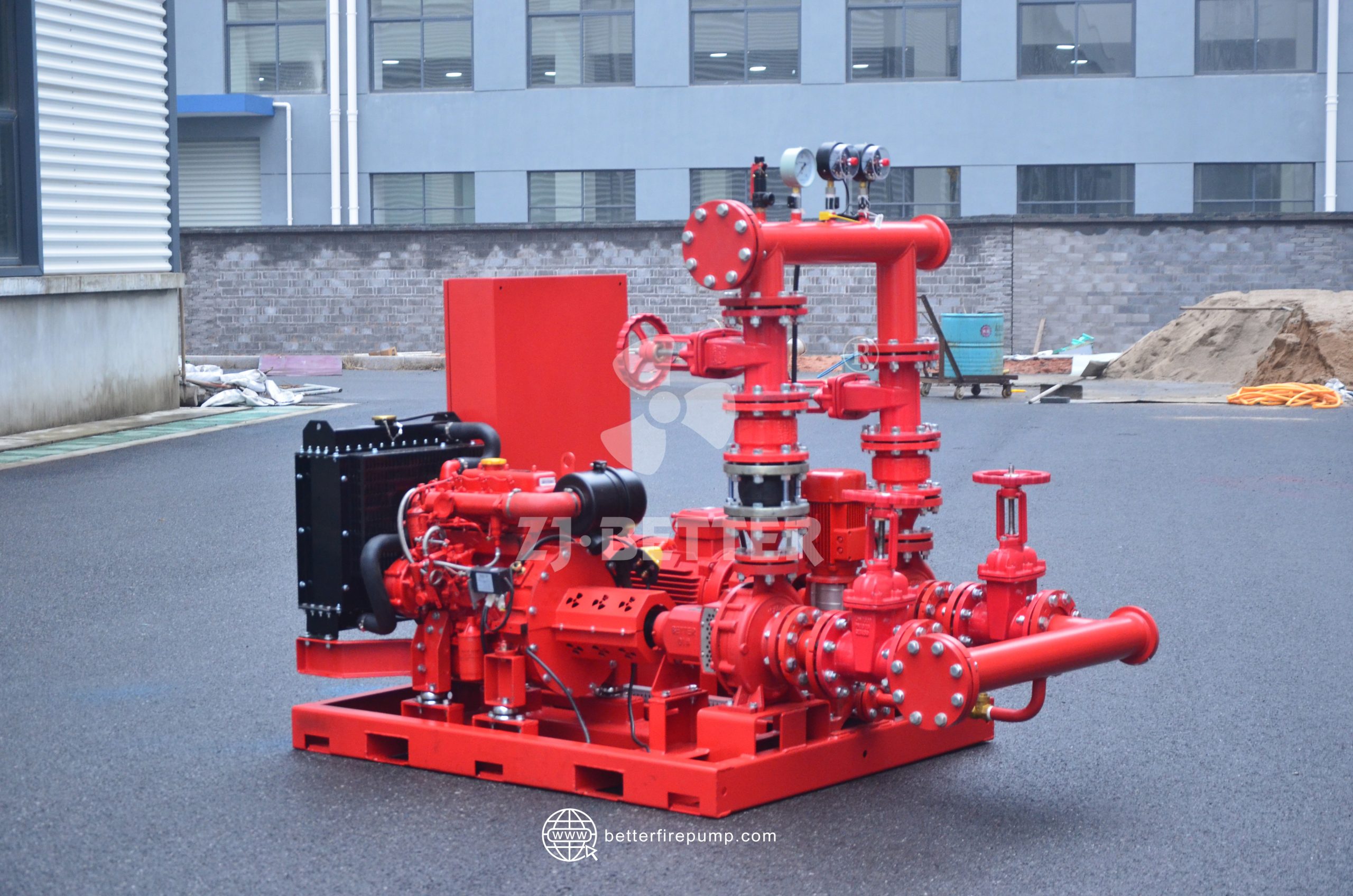

The horizontal electric multistage fire pump is engineered for super high-rise buildings, offering high head, strong system adaptability, and intelligent control. Discover its key role and application trends in modern fire protection systems.

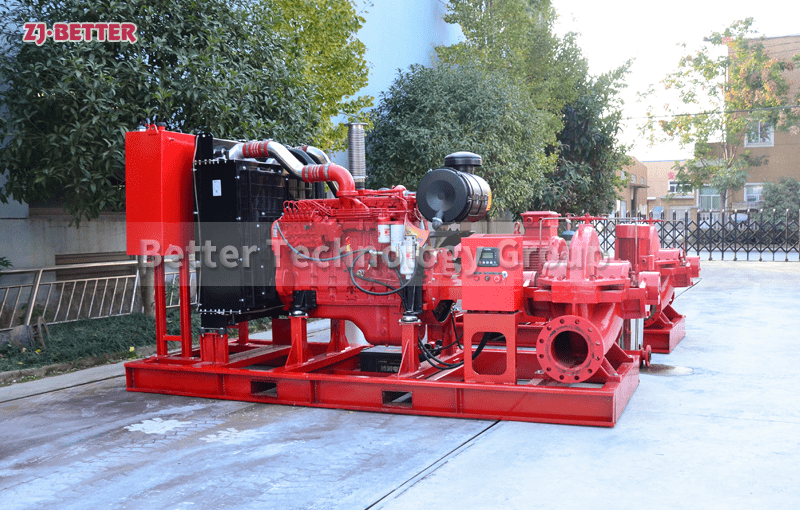

As urban architecture continues to reach new heights, fire protection systems for super high-rise buildings face unprecedented challenges. In such complex environments, ensuring that fire pump systems offer sufficient head, stable pressure output, and seamless system integration becomes a critical issue in both design and operation. The horizontal electric multistage fire pump, with its outstanding technical features and high customizability, is increasingly becoming a key component in high-rise fire protection engineering.

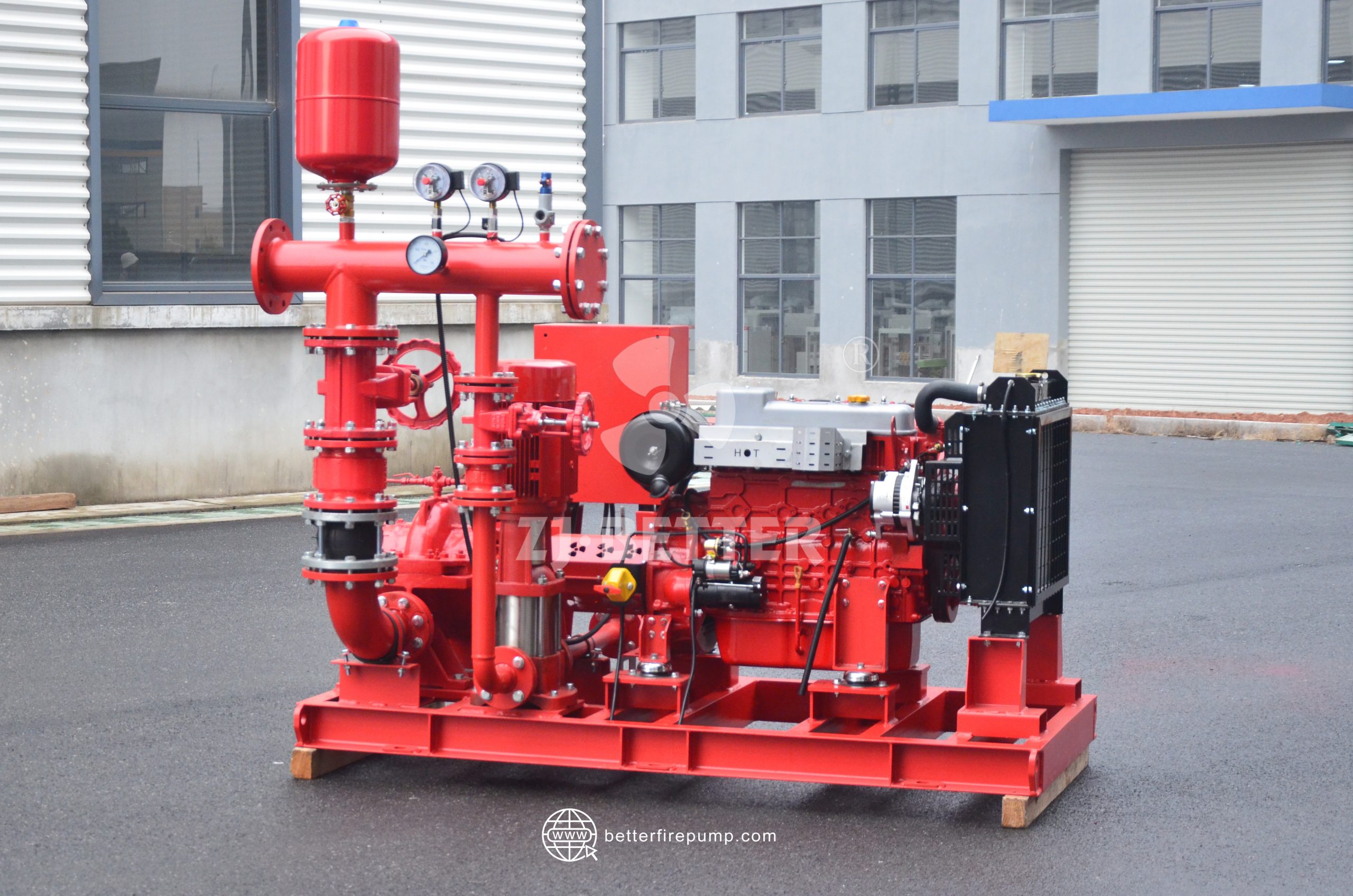

One of the core advantages of horizontal electric multistage pumps lies in their exceptional high-head output. Utilizing a multistage impeller arrangement, these pumps can efficiently overcome the significant vertical pressure losses required in tall buildings. This capability is especially vital for structures exceeding 150 meters in height, where conventional single-stage pumps struggle to deliver adequate pressure. The multistage design ensures stable high-pressure water supply during both the system start-up phase and peak fire demand periods.

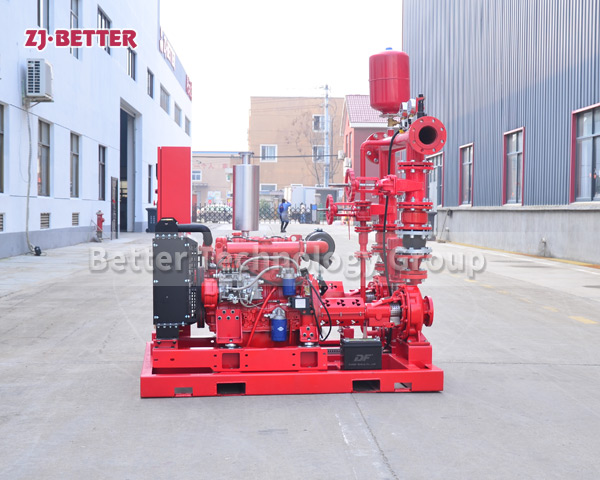

Moreover, the horizontal configuration allows for better space utilization, especially in pump rooms with limited or irregular layouts. The electric drive system provides fast response, high startup efficiency, and seamless integration with modern intelligent control systems. When combined with VFDs (Variable Frequency Drives), remote monitoring modules, and fire control cabinets, these pumps support automated operations such as remote start/stop, pressure feedback regulation, and fault alarms. This significantly enhances the overall automation level while reducing manual intervention.

In terms of system adaptability, horizontal electric multistage pumps offer flexible configurations in inlet/outlet sizes, connection interfaces, pressure ratings, and flow capacities based on project-specific requirements. The modular component design allows for easy maintenance and part replacement, optimizing long-term operational efficiency and cost-effectiveness. Pump materials like cast iron or stainless steel ensure resistance to corrosion and suitability for high-temperature, high-humidity fire environments.

Market trends indicate a rising demand for horizontal multistage electric fire pumps, driven by stricter fire safety regulations and heightened scrutiny of fire protection capabilities in tall buildings. Their performance, reliability, and automation features are now becoming industry benchmarks in the fire system designs of skyscrapers, commercial complexes, and office tower clusters.

As a professional fire pump manufacturer, we remain committed to advancing pump performance and technology. Our solutions adhere to NFPA, GB, and CE standards, ensuring global applicability and quality assurance. The horizontal electric multistage fire pump is not only a robust supplement to complex fire systems but also a fundamental pillar in the pursuit of safer, smarter high-rise architecture.

.jpg)