Fire pumps can be used to transport all kinds of liquids

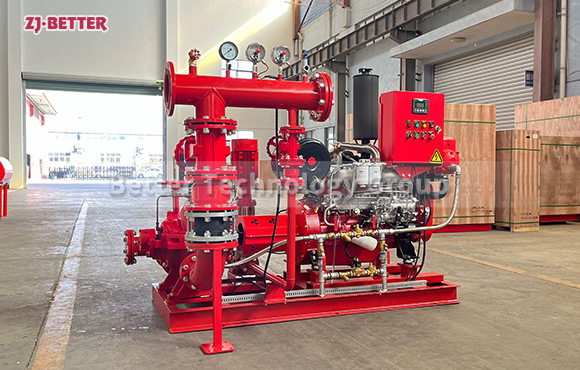

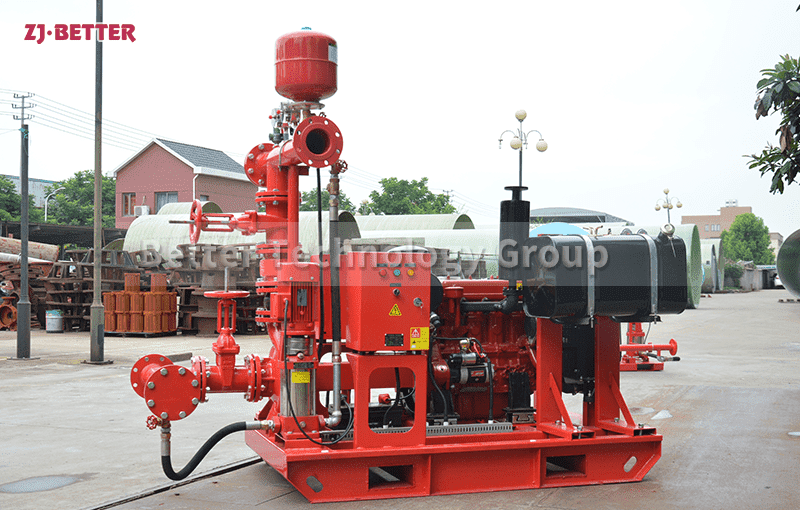

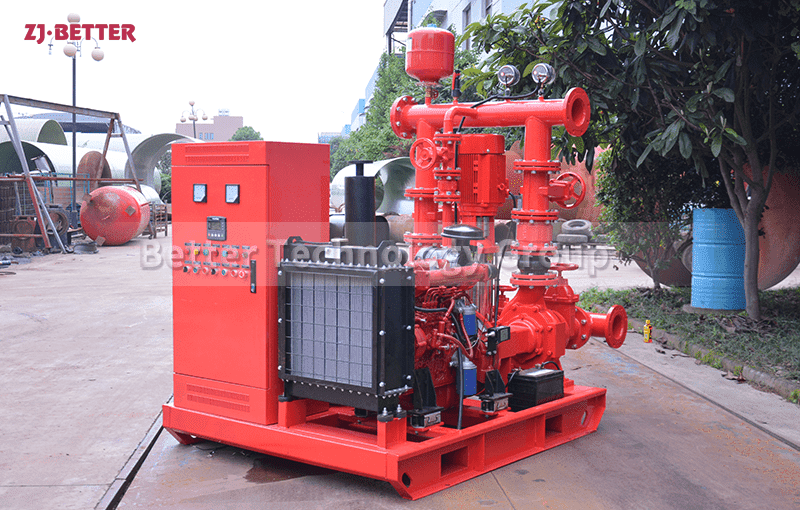

The fire pump is used to transport various liquids. It is an ideal pump and fire system for building civilized factories, non-leakage, and non-polluting civilized workshops. It is often installed on fire extinguishing systems, fire trucks or other fire-fighting facilities to transport water. Or a special pump for foam solution fire extinguishing. Pipeline fire pumps are widely used in water treatment, environmental protection, fire protection and other departments.

In production and life, fire pumps have the characteristics of a wide range of applications, such as in water treatment, fire safety and other departments. Fire pumps can not only be used in fire protection systems, multi-stage fire pumps can also be used in industrial production and urban construction, including industrial and urban water supply and drainage, and pumping water for high-rise buildings. Engineering fire pumps are used for fire pumps in engineering sites such as fire hydrant systems, water sprinkler fire extinguishing systems, and foam fire extinguishing systems.