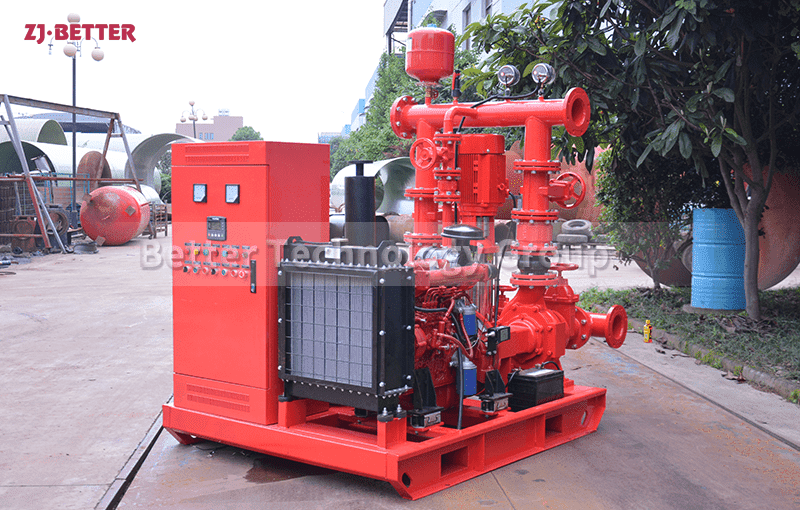

Complete Diesel Fire Pump System with Main Pump and Pressure Maintaining Function

The complete diesel fire pump system integrates the main pump’s water supply and pressure stabilization functions. It adopts independent diesel power and has the ability to start quickly, output stable pressure, and run continuously. It is suitable for large-scale fire protection projects and environments with unstable power, ensuring the safe and reliable operation of the fire protection pipeline network.

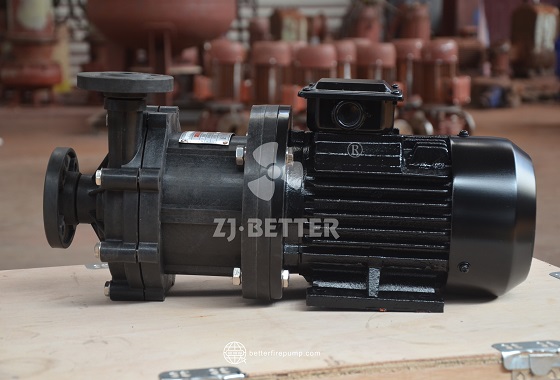

Complete diesel fire pump systems are comprehensive fire-fighting water supply solutions designed for various engineering projects with extremely high reliability requirements. Their core advantage lies in the unified integration of the main fire pump, diesel power system, pressure stabilizing and replenishing device, control system, and necessary piping components, ensuring stable and reliable operation throughout the standby, startup, and continuous operation phases. These systems use diesel engines as the primary power source, operating completely independently of external power supplies. They can continue to operate normally even during power outages, power fluctuations, or unstable power conditions, making them particularly suitable for industrial parks, large warehousing and logistics centers, energy facilities, transportation hubs, and other critical infrastructure projects. The main fire pump in the system typically employs a high-efficiency centrifugal pump structure, with the pump body made of high-strength materials, possessing excellent pressure resistance and impact resistance. The internal hydraulic flow channel is optimized to effectively reduce energy loss, enabling the equipment to stably output the design flow rate and head under rated operating conditions, meeting the fire protection code requirements for fire water pressure and supply capacity. The complete diesel fire pump system boasts significant advantages in starting performance. Through the coordination of automatic control logic and pressure monitoring devices, when the fire pipeline pressure drops or a fire signal is triggered, the system can quickly complete the diesel engine startup, pump loading, and pipeline water supply process, establishing stable pressure in a short time and gaining valuable time for initial fire suppression. Pressure stabilization and replenishment are crucial components of this system. By configuring pressure stabilizing devices and pressure storage tanks, the system continuously maintains the fire pipeline pressure during normal standby, reducing frequent main pump starts, effectively reducing equipment wear and energy consumption, and ensuring the pipeline remains within the design pressure range, thereby improving the overall response efficiency and operational stability of the fire protection system. The diesel engine plays a key power role in the system, characterized by stable torque output and strong load adaptability. It can maintain reliable speed under prolonged high-load operation, providing continuous power support to the fire pump and ensuring that insufficient power does not affect water supply during fire suppression. The complete diesel fire pump system prioritizes structural integrity and ease of installation. The engine, pump set, pressure stabilizing device, and piping components are typically mounted on a reinforced base, resulting in a compact and rational layout that facilitates overall transportation and on-site placement, shortening the construction cycle and reducing installation difficulty. The system’s control device offers multiple operating modes, enabling manual control, automatic start-up, and remote signal linkage. It also provides real-time monitoring of operating status and promptly issues alarms in case of abnormal conditions, facilitating management and maintenance by operations and maintenance personnel and improving the safety and controllability of the fire protection system. Addressing the continuous operation requirements of engineering projects, this type of system fully considers the selection of key components and structural reinforcement. By strengthening the shaft system design, optimizing bearing configuration, and improving cooling and lubrication methods, the pump set maintains stable performance under long-term continuous operation, reducing the probability of failure and extending equipment lifespan. The complete diesel fire pump system also excels in environmental adaptability. Its protective design allows the equipment to operate stably in high-temperature, high-humidity, or dusty industrial environments, making it less susceptible to external conditions and suitable for installation in indoor pump rooms or semi-open-air locations. The system boasts significant advantages in maintenance and management. Its clear structure and easy-to-inspect and replace key components, with routine maintenance focusing primarily on the fuel system, lubrication status, and periodic trial runs. The standardized maintenance procedures help ensure the equipment maintains optimal operating condition during long-term standby. For fire protection projects of varying scales and types, the complete diesel fire pump system can be flexibly configured according to design requirements, including parameters such as flow rate, head, interface specifications, and pressure stabilization device capacity, meeting diverse fire protection system design requirements. Before leaving the factory, the equipment typically undergoes rigorous performance testing and operational checks to ensure all indicators meet design standards and engineering requirements, providing reliable assurance for project delivery and subsequent operation. Overall, the complete diesel fire pump system achieves high reliability and stability in fire protection water supply by organically combining the main pump’s water supply with pressure stabilization and replenishment functions. It is particularly suitable for fire protection projects with high requirements for safety and continuous operation, demonstrating excellent practical value and engineering adaptability in real-world applications.