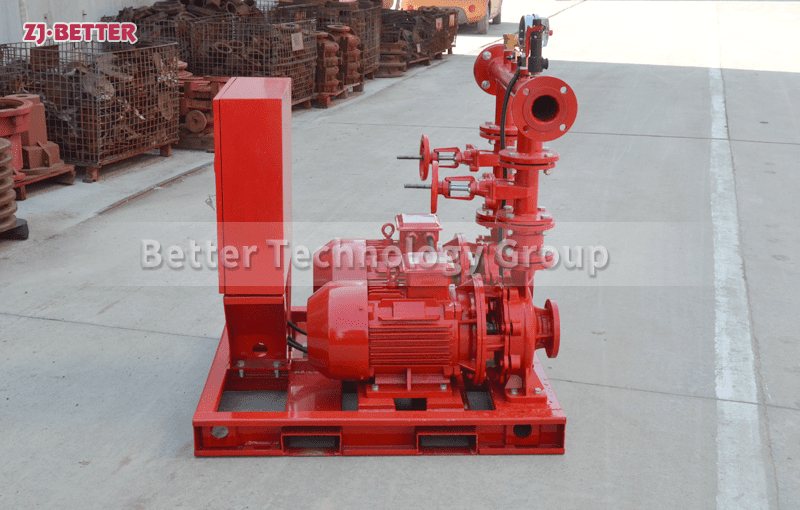

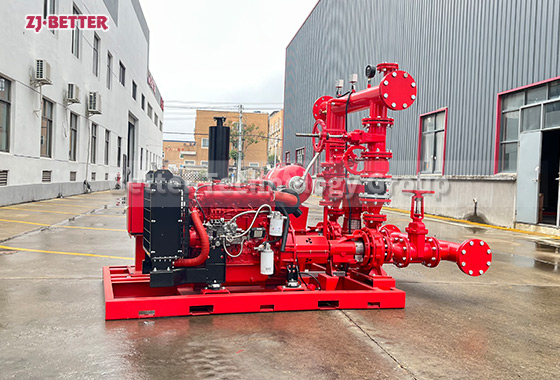

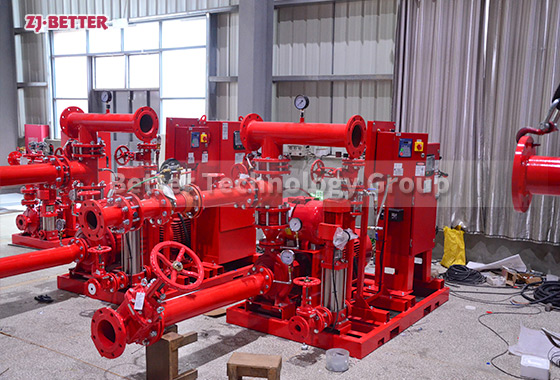

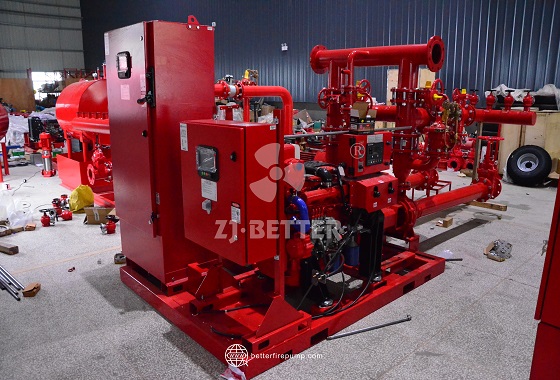

Fixed Fire Pump Unit Designed for Continuous Standby Fire Protection Systems

Stationary fire pump units are designed for long-term fire protection systems, featuring rapid start-up, continuous and stable operation, high head and large flow output, and intelligent control. They are suitable for building and industrial fire water supply systems, ensuring safe and reliable emergency water supply during fires.

Stationary fire pump units are core water supply equipment in fire protection systems of various buildings and industrial sites. Their main function is to continuously and stably provide fire-fighting water to the fire protection network in the event of a fire, meeting the design pressure and flow requirements. The stationary fire pump units referred to in the fifth heading are specifically designed for fire protection systems on continuous standby, offering significant advantages in reliability, stability, and long-term operational capability. These fire pump units typically employ an electric motor drive structure, achieving high-efficiency energy conversion through a rationally matched pump body, hydraulic model, and high-performance motor. While meeting fire protection regulations, they also consider the durability and economic efficiency of the equipment. The entire system is structurally designed with emphasis on overall rigidity and installation stability. The pump body, motor, base, and inlet/outlet piping are all uniformly laid out and reinforced, maintaining good mechanical performance under long-term static standby and sudden start-up conditions. They are less prone to vibration displacement or loosening of connections, thus ensuring rapid deployment in critical situations. Stationary fire pump units excel in hydraulic performance. The pump body is typically made of high-quality cast iron or ductile iron, possessing excellent pressure resistance and corrosion resistance. The internal flow channels are optimized to effectively reduce hydraulic losses, enabling the equipment to stably output the design flow rate and head under rated operating conditions. Even in high-rise buildings, large-span factories, or systems with high pipeline resistance, reliable water supply is maintained. Addressing the stringent requirements of fire protection systems for instantaneous start-up performance, these units feature targeted optimizations in motor selection and control logic, resulting in rapid start-up response. They can reach a stable operating state shortly after receiving the start signal, avoiding insufficient water supply due to start-up delays. Stationary fire pump units emphasize continuous operation capability. The design phase fully considers the actual need for prolonged uninterrupted operation of fire pumps under fire conditions. By strengthening bearing configuration, optimizing shaft seal structure, and improving heat dissipation capacity, the equipment maintains good temperature rise control and mechanical stability even under continuous high load operation, effectively extending the overall service life of the unit. The control system of the unit is usually integrated into an independent control cabinet, featuring manual, automatic, and remote control functions. It can be linked with the fire control center to automatically start the pump unit when the system pressure drops or a fire signal is received, ensuring timely supply of fire-fighting water. Simultaneously, it monitors current, voltage, and operating status in real time during operation, improving the overall safety and controllability of the system. Stationary fire pump units also have significant advantages in maintenance and management. Their clear structural layout and easy-to-inspect and replace key components mean that routine maintenance mainly focuses on periodic checks of lubrication, electrical connections, and pipe seals. Maintenance costs are relatively controllable, making them ideal for fire protection systems that need to be on standby for extended periods. For different application scenarios, these fire pump units can be customized according to project requirements, including flow rate, head, motor power, and interface specifications. They can flexibly adapt to fire protection network designs of different scales, and can be stably used in everything from small and medium-sized commercial buildings to large industrial parks. In actual operation, stationary fire pump units typically form a complete fire water supply unit with pressure stabilizing devices, valve assemblies, and piping systems. They maintain stable output even when system pressure fluctuates or water demand changes, effectively reducing the impact of water hammer on the pipe network and equipment. The equipment surface is usually treated with anti-corrosion coating and features a striking red fire-resistant paint, meeting the identification requirements for fire equipment and enhancing weather resistance in complex environments, making them suitable for installation in pump rooms, basements, or outdoor protected areas. Stationary fire pump units are designed and manufactured in strict accordance with relevant fire protection standards and engineering specifications. From material selection to assembly, multiple quality control processes are implemented to ensure reliable performance even during long-term standby and to prevent system operation from being affected by aging or malfunctions during critical moments. In summary, these fire pump units, with their stable hydraulic performance, rapid start-up response, excellent continuous operation capability, and convenient maintenance, have become indispensable core equipment in various fire protection systems, providing a long-lasting and reliable fire water supply for buildings and industrial sites, demonstrating high safety and practical value in practical applications.