What is the important role of diesel engine fire pump?

With the characteristics of full sealing, no leakage and corrosion resistance, fire pumps are widely used in environmental protection, water treatment, fire protection and other departments. They are ideal pumps for building non-leakage, non-pollution civilized workshops and civilized factories. Our commonly used fire pumps are electric fire pumps and diesel engine fire pumps. The difference between the two is that the electric fire pump needs power system supply. If the power is cut off, the diesel engine fire pump can be started at any time to make up for the original position of the electric fire pump.

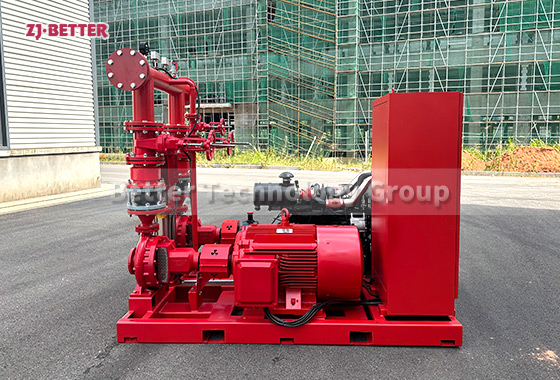

Electric fire pumps can supply fire water for general occasions. Diesel engine fire pumps are aimed at fire water supply for high-flow and high-lift occasions, and the diesel engine has good starting characteristics, fast start-up speed, strong overload capacity, and it does not need to run and stand by all the time, saving energy. efficient. Diesel engine fire pumps have complete performance and a wide range of models. They can be used in single-stage single-suction pumps, multi-stage single-suction pumps, self-priming pumps, long-axis pumps, etc., and can also be used in combination and in parallel, with a wide range of flow and pressure. Diesel engine fire pumps are widely used for fire water supply in warehouses, docks, airports, petrochemical, power plants and other industrial and mining enterprises. Larger flow and head. The temperature of the conveying medium can reach 80°C.