Control-Panel Jockey Pump Set: Key Equipment for Fast Fire System Startup Response

The electrical control cabinet type pressure stabilizing pump set is an intelligent complete set of equipment used for maintaining the pressure of fire protection pipeline network. It has the advantages of automatic pressure replenishment, rapid response, energy-saving operation and multiple electrical protections. It is suitable for high-rise buildings, factories, warehouses and various fire protection systems to achieve stable pressure guarantee and reliable main pump start-up support.

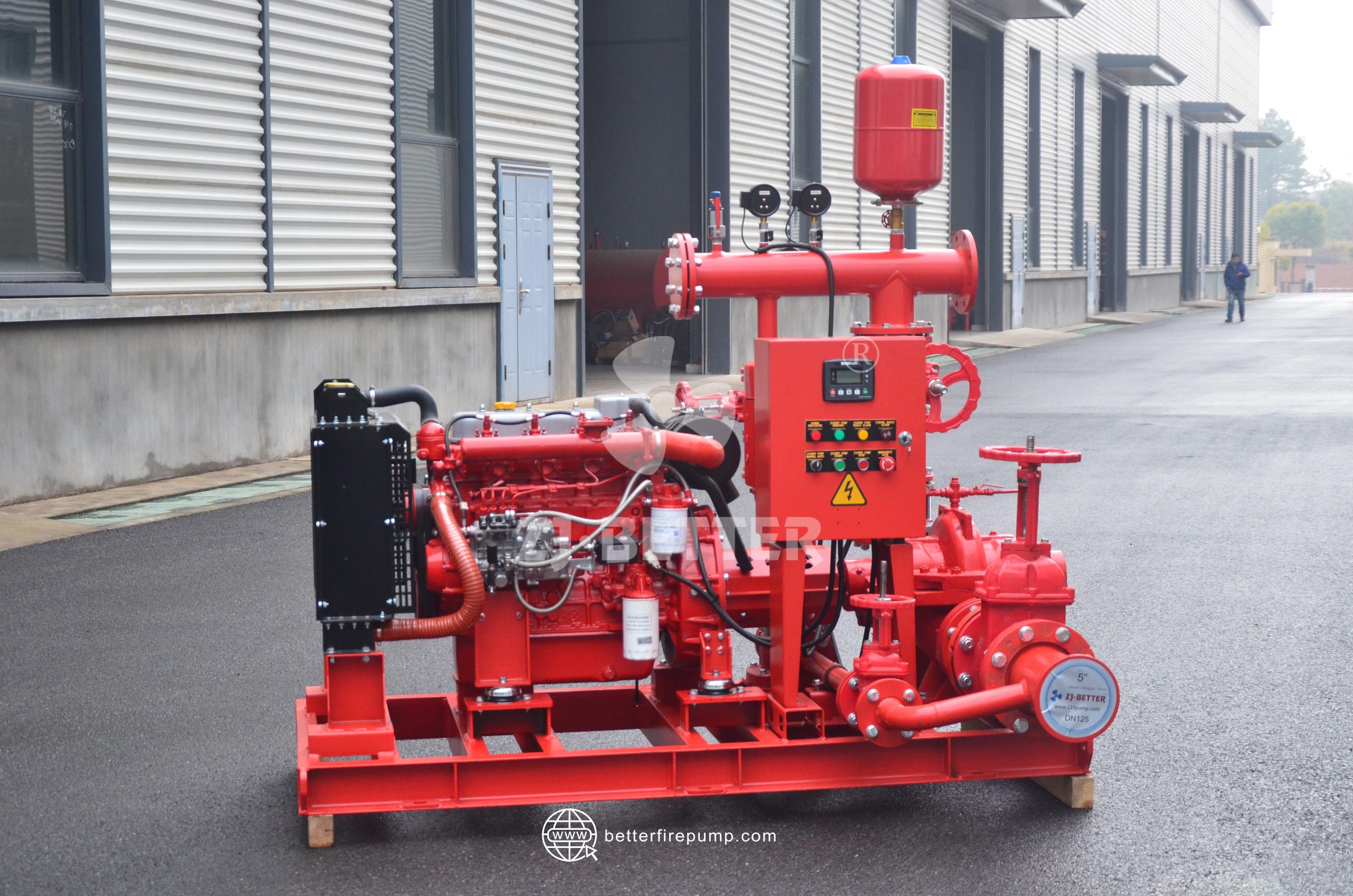

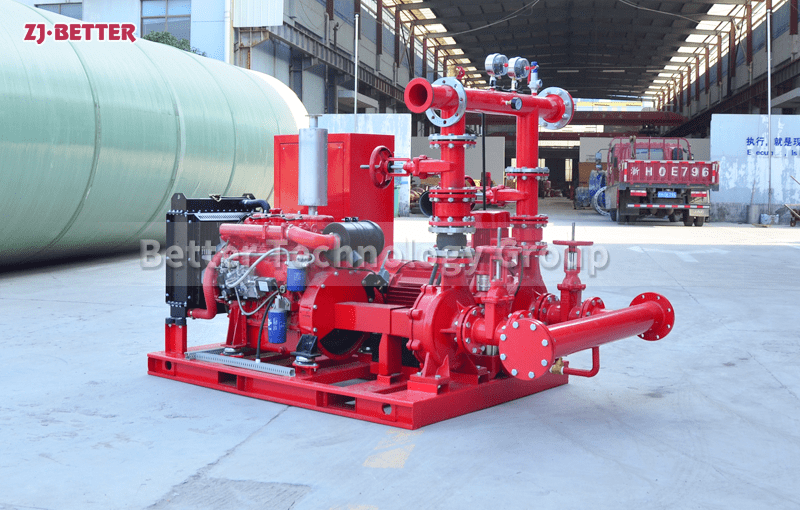

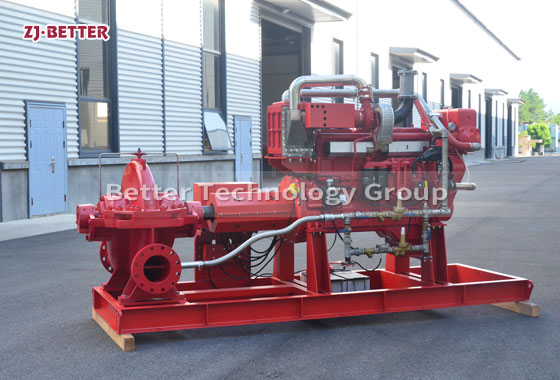

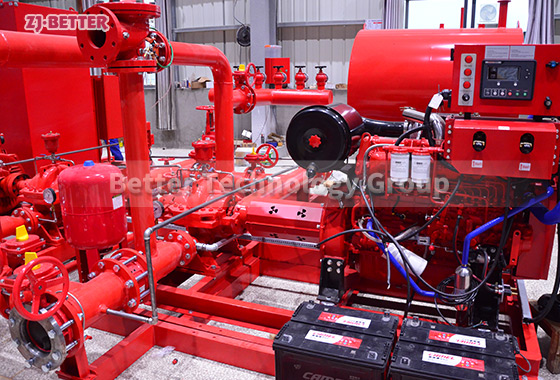

As an indispensable key device in modern fire protection systems, the cabinet-type pressure-stabilizing pump set plays a crucial role in ensuring the main fire pump can start quickly and without delay in the event of a fire by continuously maintaining the preset pressure of the pipeline network, thereby significantly improving the response efficiency and reliability of the entire system. This device consists of an electrical control cabinet, a pressure-stabilizing pump, a pressure tank, a sensing and protection system, and piping components. Through intelligent control, it achieves multiple functions such as automatic start/stop, pressure monitoring, and fault alarms, providing stable and efficient pressure assurance for various types of buildings, factories, warehouses, and fire water supply systems. Its electrical control cabinet adopts an integrated design with standardized internal wiring and a clear operating interface. Multiple indicator lights, ammeters, voltmeters, control buttons, and an automatic/manual switching device allow operators to monitor the pump set’s operating status at any time, ensuring convenient daily maintenance and repair. The pressure-stabilizing pump uses a combination of a high-efficiency motor and an energy-saving pump, resulting in low noise, low vibration, and stable operation. It can maintain high-efficiency output under long-term continuous working conditions, making it particularly suitable for 24/7 online pressure maintenance in fire protection systems. The pressure tank is constructed of high-strength steel and utilizes a diaphragm structure to effectively separate water and gas, resulting in more stable system pressure compensation and reduced pump start-stop frequency, thus extending the overall lifespan of the equipment. This pump set boasts numerous performance advantages. Its intelligent control system automatically determines whether to start or stop the pressure-stabilizing pump based on changes in pipeline pressure, requiring no human intervention and helping to avoid potential hazards caused by sudden pressure drops. When the pressure senses a drop below the set lower limit, the pressure-stabilizing pump immediately starts to replenish pressure, quickly restoring the pipeline pressure to a safe range; when the pressure reaches the upper limit, it automatically stops, eliminating energy waste. The entire process is smooth, precise, and extremely responsive, creating favorable pressure conditions for triggering the main pump, ensuring that the main pump can be immediately put into operation when needed, thereby improving the overall safety level of the fire-fighting water supply system. In terms of material selection, the equipment employs a corrosion-resistant metal structure and a high-standard spraying process, which not only improves rust resistance but also enhances durability in outdoor or humid environments. Its stable base design provides strong earthquake resistance, making it suitable for high-rise buildings, complexes, factories, logistics centers, and other locations with extremely high safety requirements. Under various complex operating conditions, including high temperature, high humidity, dusty, or mildly corrosive environments, this pump set can still provide continuous and reliable pressure maintenance. Meanwhile, the cabinet-type pressure-stabilizing pump set has comprehensive electrical protection functions, including phase loss protection, overload protection, short circuit protection, and overpressure/underpressure alarms. Each feature ensures that the equipment can automatically shut down to avoid danger in abnormal situations, preventing equipment damage or system failure. Furthermore, the equipment supports remote monitoring and signal linkage, enabling information exchange with fire control panels, fire pumps, sprinkler systems, and fire hydrant systems, thus creating a unified and coordinated operating mode for the entire fire protection system. In terms of energy saving, the cabinet-type pressure-stabilizing pump set reduces ineffective operating time through intelligent adjustment strategies, effectively reducing energy consumption. Especially in large fire protection pipe networks, long-term operation can significantly reduce energy costs. The collaborative working mechanism of its pressure tank and control system makes the pump set operation more efficient, significantly extending the service life of internal components, reducing maintenance frequency, and lowering later operation and maintenance costs. In terms of installation and maintenance, the integrated design of this pump unit results in a compact layout and small footprint, allowing for flexible installation in pump rooms, basements, or equipment rooms. The installation process is standardized, with highly compatible interfaces, short construction cycles, and easy integration into existing systems. Maintenance requires only routine checks based on pressure gauge readings, control cabinet indications, and operating records, eliminating the need for complex disassembly. Therefore, it perfectly meets the requirements of modern engineering for efficient operation and maintenance. As a crucial component of fire protection systems, the control cabinet-type pressure-stabilizing pump unit not only enhances the automation level of the entire system but also improves emergency response speed, enabling fire equipment to quickly enter operational status within critical first seconds. This plays an irreplaceable role in reducing fire spread and protecting personnel and property. With its stable and reliable performance, intelligent operation, robust and durable structural configuration, and adaptability to various scenarios, this type of pressure-stabilizing device is gradually becoming a standardized configuration in modern building fire protection systems, providing a durable, stable, and safe pressure maintenance solution for buildings of different sizes and types.