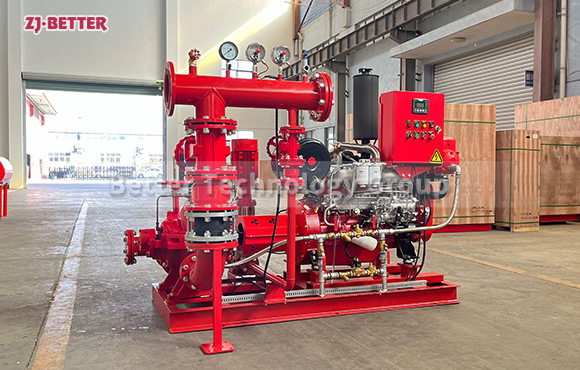

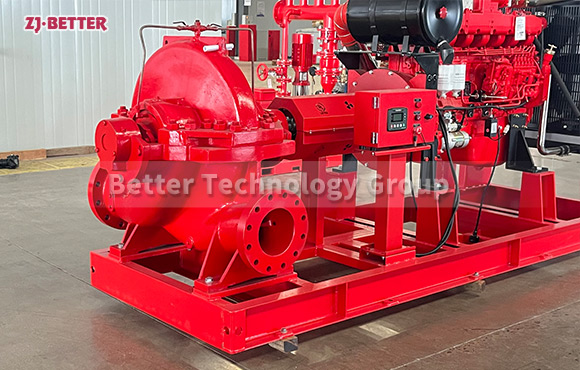

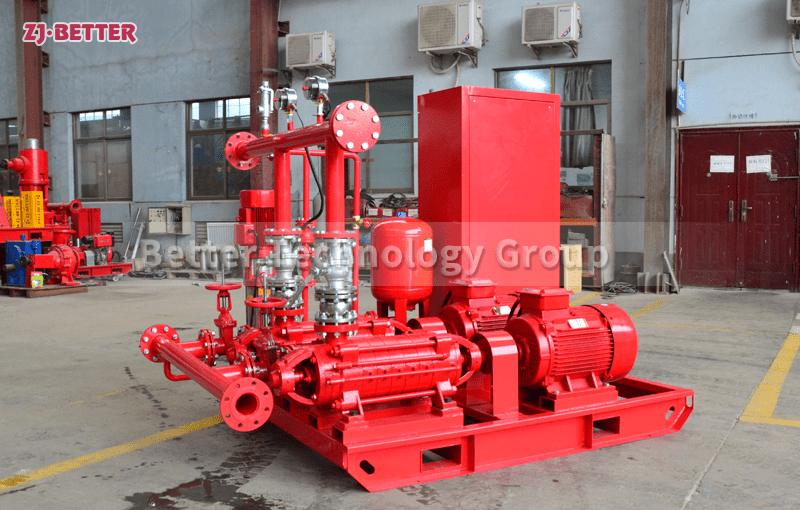

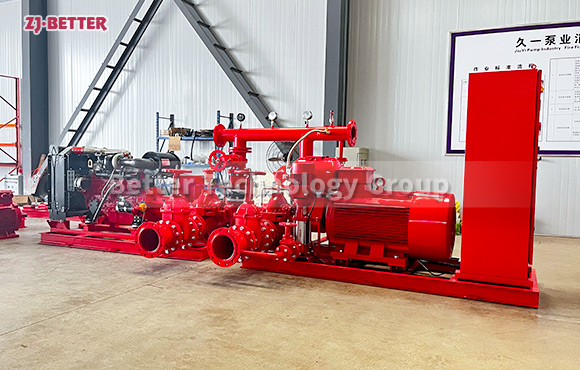

Durable Design and Powerful Performance: Reliable Diesel Fire Pump for Harsh Environments

Durable diesel fire pump with independent power supply ensures reliable water delivery without electricity, featuring fast start, high efficiency, strong adaptability, and low maintenance, ideal for mines, chemical plants, and ports.

As an essential component of modern firefighting systems, diesel fire pumps, with their durable construction and robust performance, are a reliable solution for ensuring firefighting water supply in complex environments. Whether operating in locations subject to high temperature, high humidity, dust, or frequent vibration, or facing unstable or even complete power outages, diesel fire pumps, with their independent power system and robust mechanical design, ensure a continuous supply of firefighting water in emergencies, providing stable and efficient firefighting support for various buildings, industrial facilities, and public spaces. One of their greatest advantages is their complete independence from utility power. This allows them to operate in remote areas, with limited energy infrastructure, or in extreme disaster environments, thus addressing the shortcomings of electric fire pumps in power-constrained environments. The optimized diesel engine design allows for rapid startup and reaches rated speed and pressure in a short period of time, enabling immediate response in emergencies. This high reliability allows diesel fire pumps to maximize their effectiveness in the critical early stages of a fire, effectively controlling the spread of a fire. In addition to their independent power source, diesel fire pumps also boast exceptional durability in their structural design. The pump body is typically constructed of high-strength cast iron or ductile iron, offering excellent wear and impact resistance, ensuring stable performance even in long-term, high-intensity operation. The engine, optimized for industrial specifications, is resistant to high temperatures, corrosion, and vibration, ensuring stable operation even in harsh environments. The strategic layout of the lubrication, cooling, and exhaust systems further extends the equipment’s service life and reduces the risk of downtime due to overheating or overload. The adaptability of diesel fire pumps is particularly important in complex environments. For example, in high-risk areas such as mines, chemical plants, ports, and storage and logistics centers, these equipment must not only withstand harsh environmental conditions but also meet the demands of long-term, high-load operation. With its high flow rate and powerful power, diesel fire pumps can instantly provide sufficient water pressure and volume to the firefighting network, meeting the multiple demands of sprinkler systems, fire hydrant systems, and foam fire extinguishing systems, ensuring efficient operation of the entire firefighting system. Performance stability is reflected not only in its continuous water supply but also in its energy efficiency and economical operation. The diesel engine utilizes efficient combustion technology, resulting in high fuel efficiency and reduced energy consumption during operation. Select models are also equipped with an intelligent control system that monitors engine operating status, water pressure, water flow, and oil level in real time. When an anomaly occurs, it automatically issues an alarm or even initiates a shutdown for protection, significantly improving operational safety and equipment reliability. This integration of automation and intelligence enables diesel fire pumps to maintain performance while reducing the complexity of manual intervention and enhancing management convenience. The modular design of diesel fire pumps offers significant advantages in terms of maintenance. Major components such as the engine, pump body, cooling system, and control panel utilize standardized interfaces for easy disassembly and replacement, reducing repair costs and downtime. Reasonable lubricant and coolant replacement cycles, combined with high-quality filter elements, effectively extend the service life of the engine and pump body. Due to the inherent durability of the diesel engine, maintenance frequency is relatively low, further reducing overall operating costs. In addition to its performance and structural advantages, diesel fire pumps also demonstrate meticulous safety design. Explosion-proof electrical components, shock-absorbing brackets, and multiple protective devices ensure the equipment remains safe and controllable even in extreme environments, preventing secondary risks caused by equipment failure. Some models are even equipped with remote monitoring functions. Managers can grasp the operating status of the equipment in real time through the control system, which facilitates rapid decision-making and emergency response, and improves the overall intelligence level of the fire protection system. Overall, the diesel fire pump has demonstrated its irreplaceable value in complex environments with its independent power source, strong output performance, durable structural design and intelligent control system. It is not only a reliable backing in emergency situations, but also a guarantee of stable and efficient operation in the long term. Whether facing sudden fires or high-risk industrial production scenarios, diesel fire pumps can provide users with safe, reliable and economical fire protection solutions with their stable performance, long-lasting durability and strong adaptability. It is precisely because of these outstanding advantages that diesel fire pumps have been widely used around the world and have become core equipment in fire protection systems of various high-risk industries and important facilities.