Reliable Choice for Extreme Conditions: Performance of Heavy-Duty Diesel Fire Pump

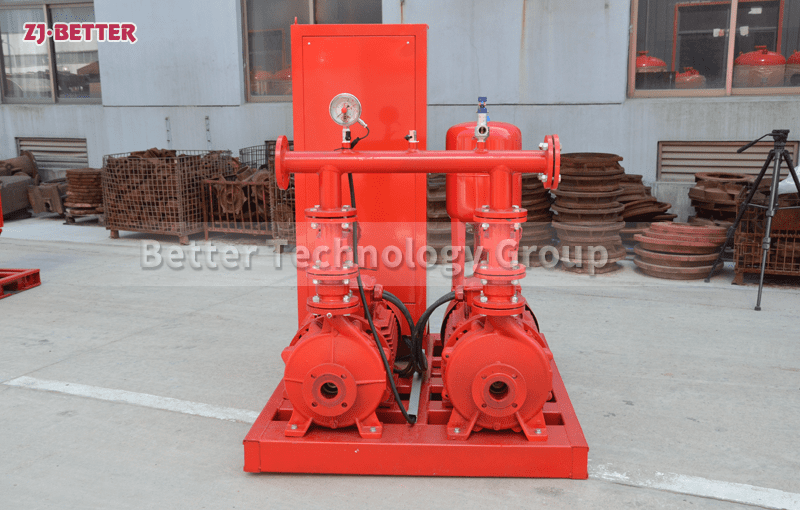

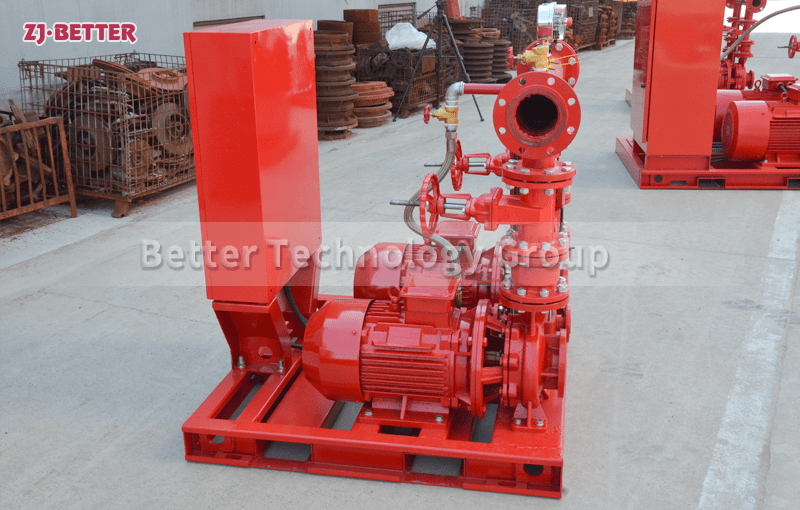

Heavy-duty diesel fire pumps are designed for extreme environments, featuring strong power output, durable structure, and excellent adaptability. They can operate stably in high and low temperatures, dusty environments, and without electricity, ensuring reliable water supply and fire safety at critical moments.

A reliable choice for extreme environments: A performance analysis of heavy-duty diesel fire pumps. As an essential core component of modern firefighting systems, heavy-duty diesel fire pumps demonstrate exceptional performance advantages in diverse and complex environments and high-intensity operations. Their design reflects the high demand for continuous water supply and stable operation in extreme environments, resulting in significant improvements in structural strength, power performance, durability, and adaptability. Compared to conventional fire pumps, heavy-duty diesel fire pumps utilize an optimized engine powertrain and pump structure to maintain stable operation in demanding conditions such as high temperature, high humidity, low temperature, dust, and unstable power supply, ensuring water supply security during critical moments. Powering these pumps is a high-efficiency diesel engine with high output power and strong torque, ensuring no performance degradation even under extended full-load operation. The diesel engine’s robust fuel adaptability allows for continuous operation even in areas with limited fuel supply, without relying on an external power grid. This independent power advantage is particularly important in remote mining areas, petrochemical sites, seaports, and field storage areas without reliable power. The powerful power system not only ensures rapid pump startup but also delivers a stable, high-pressure water flow within seconds, effectively responding to sudden fires. Furthermore, the pump body of this heavy-duty diesel fire pump utilizes wear-resistant alloy materials and a high-strength casting process, ensuring stability under high flow rates and high pressures, and resisting deformation and wear. Its optimized sealing system effectively prevents water leakage and impurities, enhancing overall durability and service life. Furthermore, the fluid dynamics of the pump’s internal flow path significantly improves water flow efficiency and head performance, enabling the unit to maintain robust water supply capabilities in complex pipe networks. Furthermore, in terms of adaptability, this heavy-duty diesel fire pump is capable of withstanding extreme climate conditions, from extreme heat to freezing temperatures. The cooling system utilizes a high-efficiency radiator and recirculating cooling to prevent engine shutdown due to overheating even in high-temperature environments. Furthermore, the combination of fuel preheating and an electric start system enables the pump to start quickly in sub-zero temperatures, providing reliable support for firefighting operations in cold regions. Furthermore, the pump unit’s corrosion-resistant design makes it suitable for coastal areas with high salt fog and humidity, effectively preventing performance degradation caused by environmental corrosion. Regarding the control system, the heavy-duty diesel fire pump is equipped with an intelligent electronic control panel that monitors key parameters such as speed, water pressure, temperature, and fuel status in real time. It automatically generates alarms and initiates protective measures if an abnormality occurs, significantly enhancing equipment safety and reliability. Select models also support remote monitoring and automatic start/stop functions, allowing management personnel to operate the equipment from the control room or remote terminal. This not only improves operational convenience but also reduces the frequency of manual inspections. Regarding maintenance, the heavy-duty diesel fire pump was designed with ease of maintenance in mind, with a rational layout of key components and strategically located access points, facilitating daily inspection and maintenance. The separate structure between the diesel engine and pump body reduces vibration and facilitates replacement of wearing parts, thereby extending the overall equipment life. Furthermore, upgraded fuel filtration and lubrication systems further minimize damage to the equipment caused by impurities and reduce maintenance costs. In addition to their vital role in emergency firefighting, heavy-duty diesel fire pumps also have extensive applications in industrial production and emergency water supply systems. For example, in the petrochemical industry, this equipment can rapidly supply water in the event of a sudden fire, creating a stable water curtain that effectively isolates the source of the fire. In the mining industry, it can withstand the harsh effects of dust and moisture, ensuring safety in underground operations. In ports, terminals, and warehouses and logistics centers, it provides high-flow, high-pressure water supply to meet the needs of large-scale firefighting. These practical application scenarios fully demonstrate the versatile performance and core value of heavy-duty diesel fire pumps. More importantly, with the increasing demand for reliability and sustainability in modern firefighting, heavy-duty diesel fire pumps optimize fuel consumption and emissions, offering energy-saving and environmentally friendly features while complying with international firefighting equipment standards, providing users with long-term and stable protection. Their rugged structure, powerful power, excellent adaptability, and intelligent control system combine to form their unique advantages, making them a core component of firefighting systems in various high-risk locations. In short, with their excellent power output, strong environmental adaptability, durable structural design, advanced intelligent control, and simple maintenance, heavy-duty diesel fire pumps are a reliable choice for withstanding extreme environments and ensuring fire water supply. It is not only an important equipment to ensure the safety of life and property, but also an embodiment of the close integration of modern fire protection technology and engineering practice. It represents the high-end level and development direction of the emergency water supply system and will continue to play an irreplaceable role in the future fire safety system.