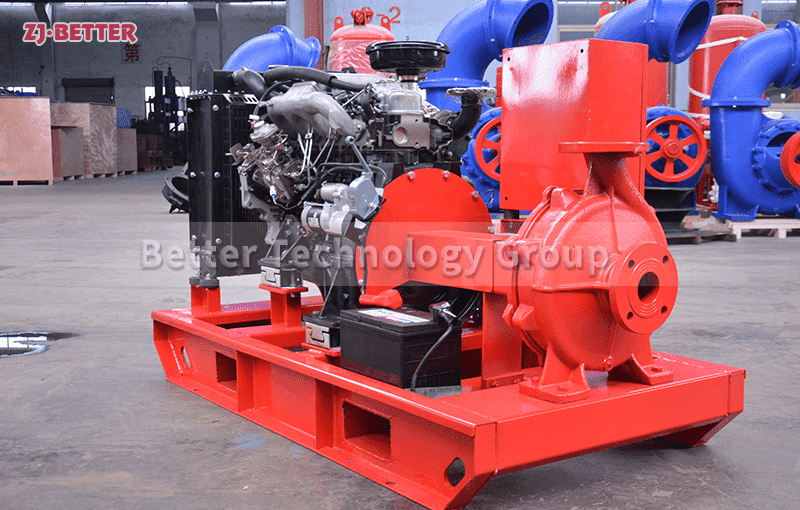

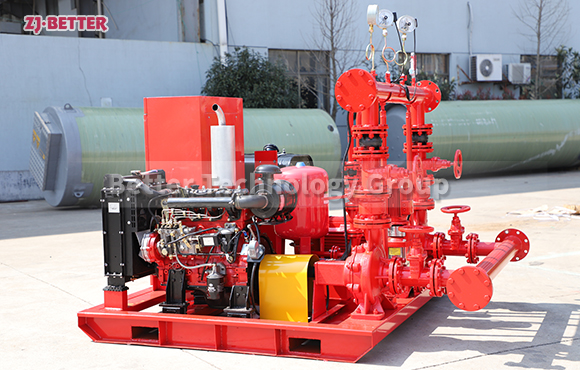

Durable and Energy-Saving Diesel Fire Pump Set to Reduce Operating Costs

Durable and energy-saving diesel fire pump set, with high efficiency and energy saving, stable water supply, fast start and multiple safety protection functions, suitable for fire water supply needs in industry, municipal administration, high-rise buildings, etc., with reliable operation and easy maintenance.

The durable, energy-efficient diesel fire pump unit is a fire water supply system designed for long-term, high-intensity operation. Powered by a high-quality diesel engine, it combines efficient pumps with an intelligent control system, providing reliable fire protection for a wide range of industrial, commercial, municipal, and large-scale infrastructure applications. Designed with high-intensity operation, continuous operation, fuel efficiency, and easy maintenance in mind, this pump unit enables rapid startup and stable water supply in emergency situations like fires, while maintaining low energy consumption and low failure rates during daily operation, significantly reducing overall cost of ownership. A key advantage of this unit is its durability. Core components, such as a high-strength cast iron pump body, stainless steel shaft and seals, high-temperature resistant coatings, and a specially heat-treated impeller, are constructed from wear- and corrosion-resistant materials. These features extend its service life and ensure stable operation in harsh environments such as high temperature, high humidity, and high dust levels. The diesel engine in the pump unit utilizes internationally standardized production processes, ensuring efficient fuel combustion, stable power output, and zero power degradation even during prolonged, high-load operation. Energy efficiency is another key highlight of this pump unit. By optimizing the fuel injection system, refining the intake and exhaust structure, and reducing transmission losses, this unit achieves a 10%-15% reduction in fuel consumption compared to conventional models at equivalent flow and head conditions, significantly saving users significant fuel costs over extended operation. Furthermore, the pump unit is equipped with an intelligent electronic control unit that automatically adjusts engine speed based on real-time pressure and flow, ensuring on-demand water supply, avoiding energy waste, and extending engine life. This diesel fire pump unit also boasts excellent starting performance. Its preheating system and high-performance electric starter enable rapid startup even in sub-zero temperatures and humid environments, ensuring immediate operational readiness during a fire. Its control system is compatible with both manual and automatic modes, allowing users to operate directly from the control panel or connect it to the fire alarm system for fully automated startup. Regarding safety, the pump unit is designed with multiple protection features, including low oil pressure protection, high water temperature alarm, overspeed protection, and water shortage shutdown. Upon detecting an abnormality, the system automatically issues an alarm or shuts down the unit, preventing equipment damage and ensuring personnel safety. Furthermore, the equipment features low maintenance costs, a rational structural layout, ample access to key areas for maintenance, simple routine maintenance, and easy replacement of wearing parts, minimizing downtime. Flexible installation is also a key advantage, with the option of a fixed or mobile base to suit user needs, adapting to diverse installation environments, including indoor equipment rooms, outdoor platforms, and temporary projects. The overall frame utilizes high-strength steel construction, offering excellent seismic and corrosion resistance, making it suitable for long-term use in coastal, high-humidity, and dusty environments. The pump unit demonstrates excellent performance, with a maximum flow rate capable of supplying water from hundreds to thousands of tons per hour. Its wide head range meets the high-pressure, stable water supply requirements of high-rise buildings, chemical parks, and large storage bases. In continuous operation tests, the unit demonstrated uninterrupted and stable operation for over 72 hours with minimal performance fluctuations, demonstrating its reliability and durability in emergency situations. As a fire water supply system that combines high performance with low energy consumption, the durable and energy-saving diesel fire pump unit is not only suitable for firefighting systems, but also for municipal water supply, industrial cooling, agricultural irrigation, and other applications. Its versatility provides users with a high return on investment. In general, this pump set has outstanding performance in terms of durability, energy saving, reliability, intelligence and easy maintenance. It can help users significantly reduce operating costs while ensuring the safety of life and property. It is one of the indispensable core equipment in modern fire water supply systems.