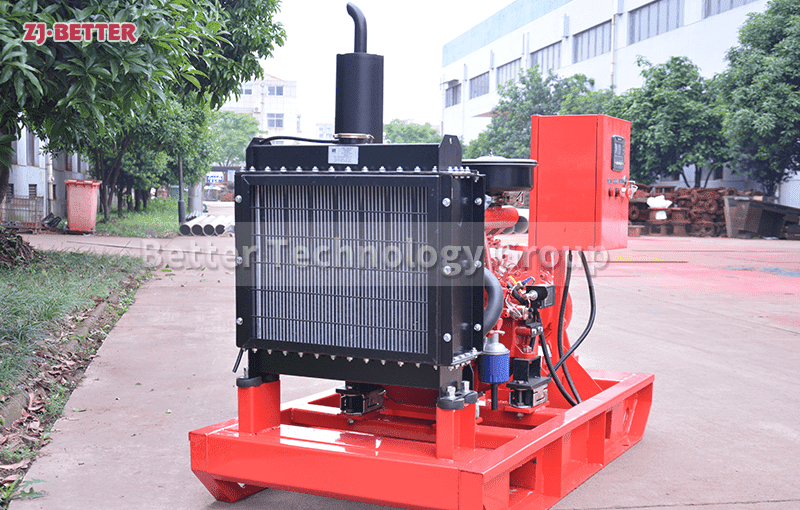

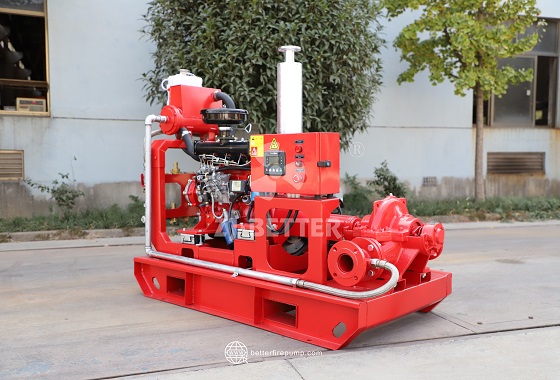

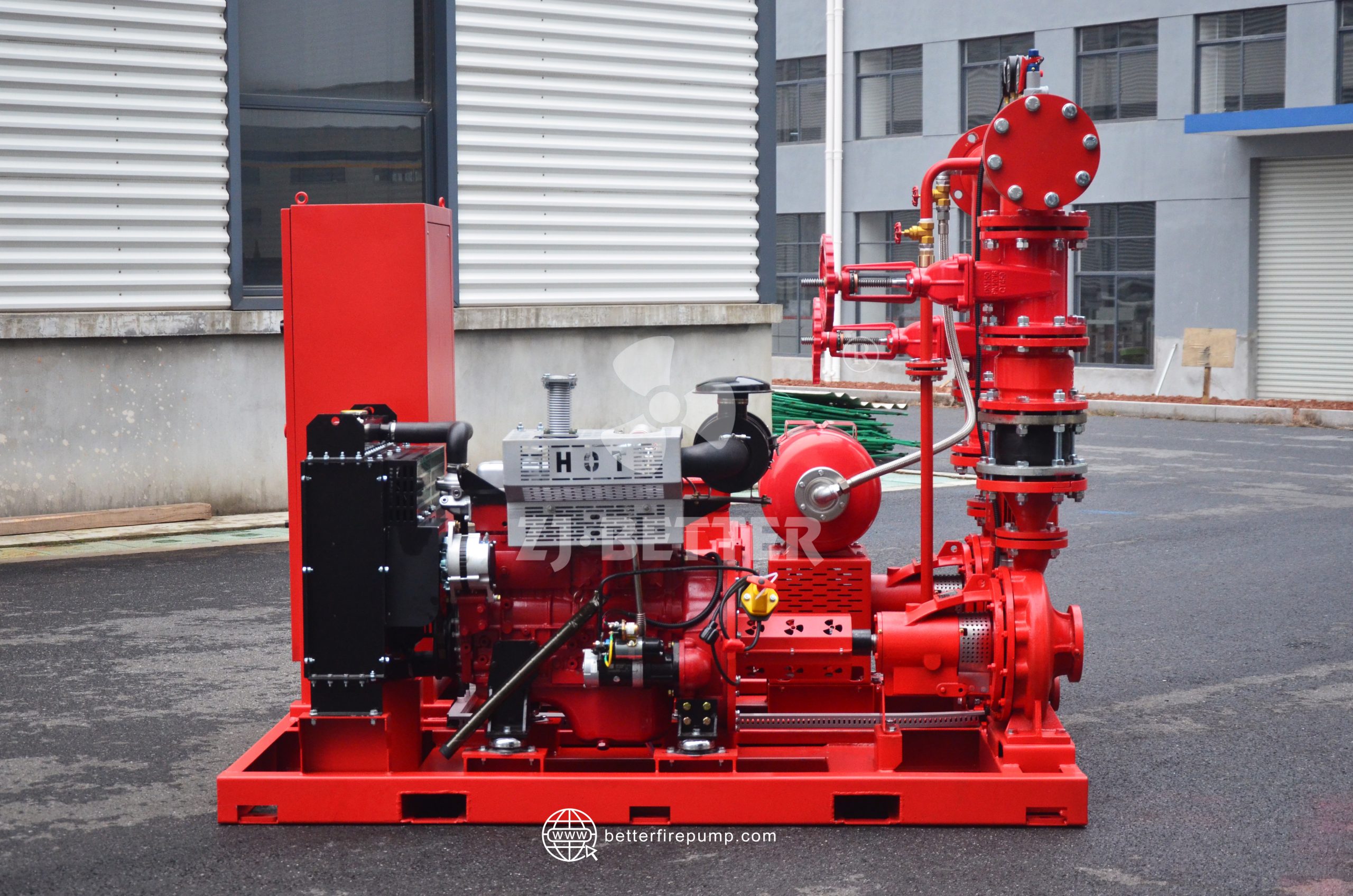

XBC-ZWC Diesel Self-priming Pump

The so-called self-priming pump does not require irrigation before starting, and after a short period of operation, the water can be sucked up by the function of the pump itself and put into normal operation.

Self-priming pumps are divided into the following categories according to their working principles:

(1) Gas-liquid mixing type (including internal mixing type and external mixing type);

(2) Water ring wheel type;

(3) Jet type (including liquid jet and

Self-priming pump is also a kind of centrifugal pump. It is just a high-height centrifugal pump with high water storage capacity. It does not require a foot valve in the suction line. Centrifugal pump products can absorb water after the first irrigation, so self-priming pumps can also be called centrifugal pumps. It can also be called a self-priming centrifugal pump.

The self-priming pump has the advantages of compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long life, and strong self-priming ability. The advantages of centrifugal pumps are compact structure, wide range of flow and head, suitable for mildly corrosive liquids, multiple control options, uniform flow, stable operation, low vibration, no need for special shock absorption foundation, equipment installation, Maintenance and repair costs are low.