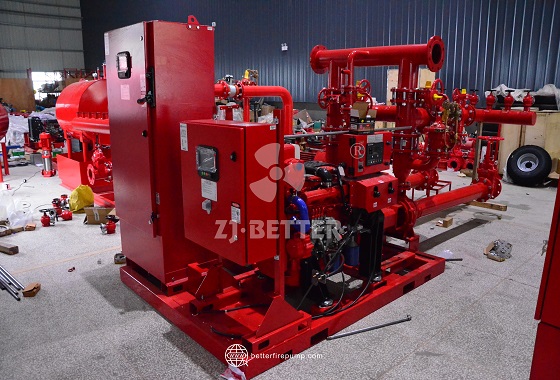

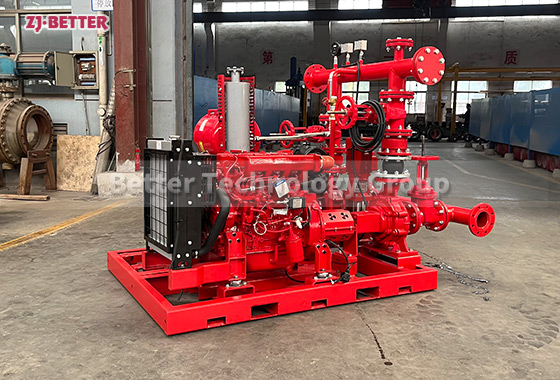

Smart Control Fire Pump Unit for Stable Operation and Enhanced Fire Protection

The intelligently controlled fire pump unit integrates high-efficiency drive, automated operation, and multiple safety protections. It is suitable for high-rise buildings, industrial parks, warehousing and logistics, and municipal projects. It ensures rapid water supply and stable operation in the event of a fire, comprehensively improving the reliability and safety of the fire protection system.

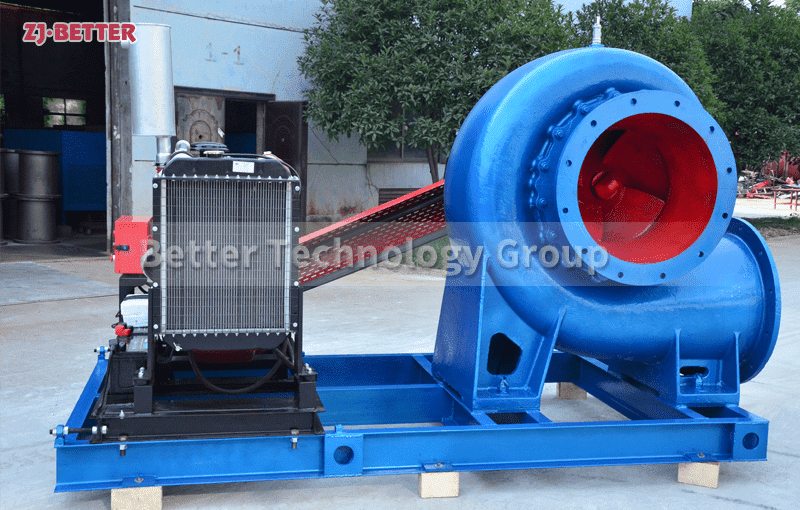

Intelligently controlled fire pump units are modern fire water supply equipment that integrates advanced technology, stable performance, and efficient operation. They not only respond quickly to fires, providing a robust water supply for firefighting operations, but also demonstrate exceptional stability and reliability during both standby and operational operations. Compared to traditional fire pump systems, the introduction of intelligent control systems significantly enhances automation, enabling the equipment to adapt to different scenarios and needs, reducing delays and errors caused by manual operation. This provides safer and more efficient fire protection for high-risk industries such as modern buildings, industrial parks, warehousing and logistics centers, municipal engineering projects, and petrochemical and power generation. The core advantage of these fire pump units lies primarily in their intelligent control systems. These units typically feature advanced electrical control cabinets and sensor systems that monitor key operating parameters such as water pressure, flow, current, and temperature in real time. These units utilize program logic to automatically start and stop the system, regulate pressure, and provide fault alarms. This intelligent control significantly reduces the need for human intervention and ensures the equipment is operational as quickly as possible in emergencies, ensuring a continuous and stable water supply. Furthermore, the intelligent control system features remote monitoring and data logging. Through the communication module, managers can remotely view operating status, historical data, and alarm logs, enabling more efficient equipment management and maintenance, enhancing the overall intelligence of the fire protection system. In terms of performance, intelligently controlled fire pump units utilize high-efficiency drive systems, with common power sources including electric motors and diesel engines, ensuring that water supply needs can be met in diverse locations. Electric motor-driven pumps are suitable for areas with stable power supplies, offering fast startup, low noise, and easy maintenance. Diesel engine-driven pumps, capable of independent operation even during power outages, are widely used in applications requiring high reliability. Regardless of the drive system, the pump body is constructed of wear-resistant materials and features a high-precision hydraulic design, ensuring high efficiency and low energy consumption even during long, intensive operation, significantly improving system stability and cost-effectiveness. During manufacturing, the units are typically equipped with high-quality bearings and seals to prevent leakage or mechanical failure under high-pressure and high-speed operation, significantly extending the equipment’s service life. Intelligent control fire pump units are designed with ease of installation and maintenance in mind. They typically utilize a modular design, with all key components and control systems centrally mounted on a unified chassis. Installation requires only plumbing and power connections, significantly shortening the construction cycle and reducing installation costs. During maintenance, the control cabinet features an intuitive interface, clear parameter visualization, and self-diagnosis to quickly pinpoint the location of problems, reducing maintenance effort and downtime, significantly saving users significant operational costs. Furthermore, the units’ compact design and small footprint make them suitable for use in limited equipment rooms or outdoor environments, particularly in high-rise urban buildings and underground facilities. Safety is a key factor in fire pump units, and intelligent control fire pump units incorporate multiple safeguards, including overload protection, overheating protection, low-voltage alarm, phase loss protection, automatic switching, and manual emergency start. These safeguards ensure immediate action in the event of an emergency and prevent further damage. Furthermore, diesel engine-driven pump units are typically equipped with a dual-battery starting system and fuel preheating device, ensuring rapid startup and operation even in low temperatures or extreme conditions. In addition, the unit’s casing and piping are treated with a high-temperature and corrosion-resistant coating, effectively resisting moisture, salt spray, and chemical corrosion in complex environments, ensuring high efficiency and stability over long-term operation. In terms of application, the intelligent control fire pump unit serves a wide range of industrial, commercial, residential, and public infrastructure applications. In high-rise buildings, its automatic pressure regulation and backup drive functions ensure uniform and stable water supply to every floor. In petrochemical plants, the unit’s durability and high performance meet the needs of continuous operation in environments with strict fire protection requirements. In municipal water supply and drainage systems and underground spaces, the unit can meet the pressure requirements of fire protection pipe networks to provide a continuous and reliable water supply. In large warehouses, logistics parks, and airport terminals, the unit’s high flow output and intelligent operation provide crucial support for fire prevention and control. The economic benefits of the intelligent control fire pump unit are also not to be underestimated. Thanks to its advanced hydraulic design and high-efficiency drive system, the unit delivers powerful hydraulic output while maintaining relatively low energy consumption, resulting in significant energy savings over the long term. Intelligent control and automated operation not only reduce labor costs but also mitigate the risk of losses due to human error. The equipment’s high durability and low maintenance requirements further extend its lifespan, resulting in a low overall cost of ownership and a significant cost-effectiveness advantage. With the continuous improvement of global fire safety standards, intelligent control fire pump units have become essential equipment that complies with various international standards. Their design and manufacturing processes are strictly adhered to NFPA, ISO, and other specifications, ensuring their competitiveness in the global market. Overall, intelligent control fire pump units, with their high-efficiency drive, intelligent control, stable and reliable performance, and flexible application range, have become an indispensable component in modern fire protection systems. They not only meet emergency water supply needs during fires but also provide stable backup for facilities during normal times, making them the optimal choice for enhancing the intelligence and safety protection capabilities of fire protection systems.

.jpg)