Precision Control and Reliable Performance: The New Safety Standard for Multi-Stage Fire Pump Systems

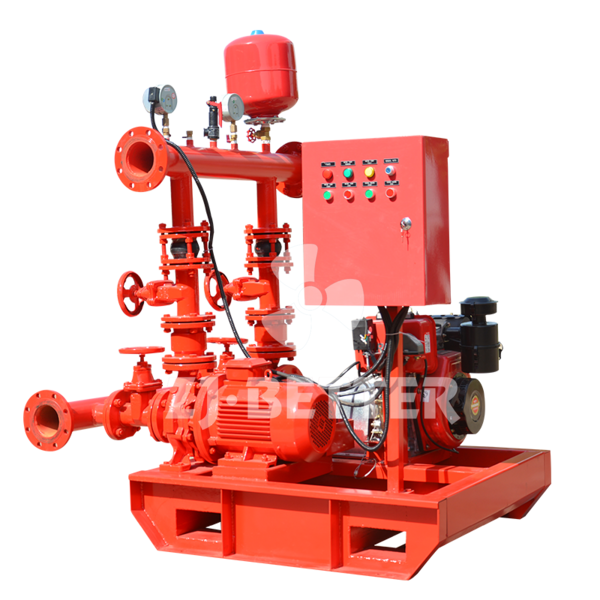

This high-performance, multi-stage fire pump system provides stable, high-pressure water supply and supports both automatic and manual control modes. It’s suitable for high-rise buildings, industrial plants, and large-scale fire protection projects. Its energy-saving, high-efficiency, low-noise, and easy-to-maintain advantages ensure continuous water supply and safe system operation during fires, making it an ideal choice for modern intelligent fire water supply systems.

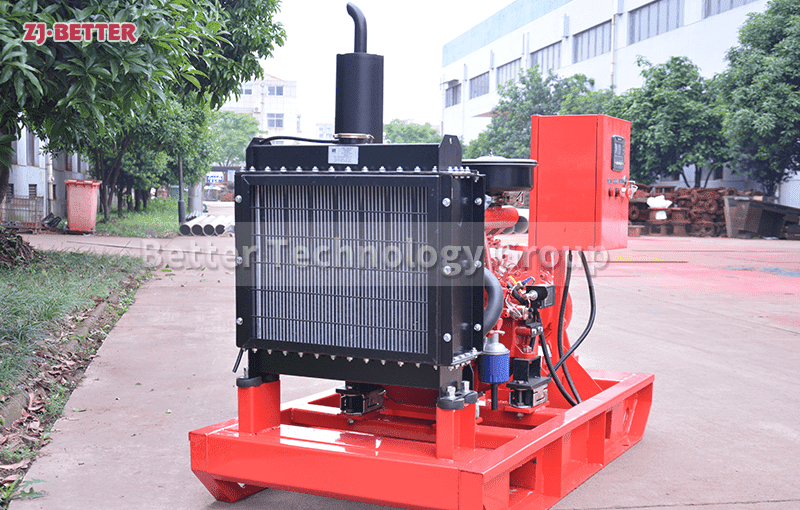

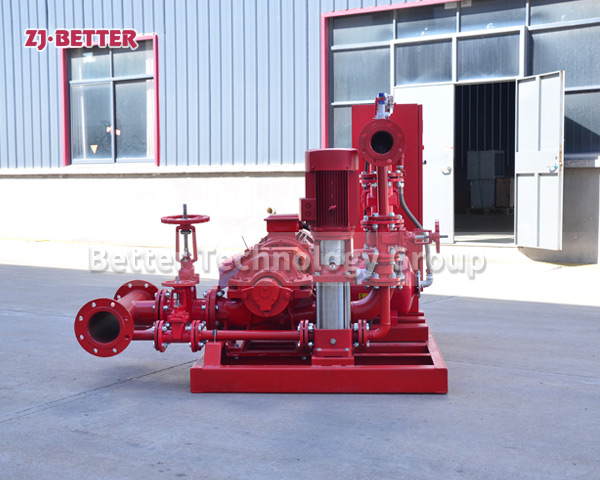

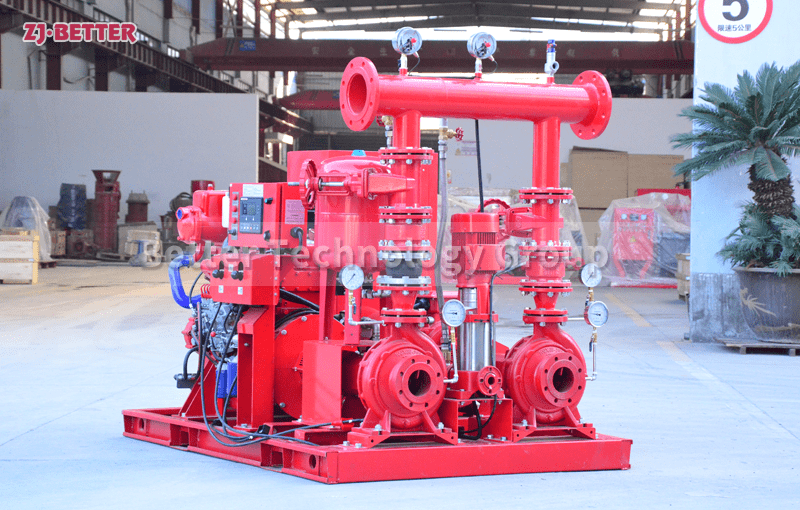

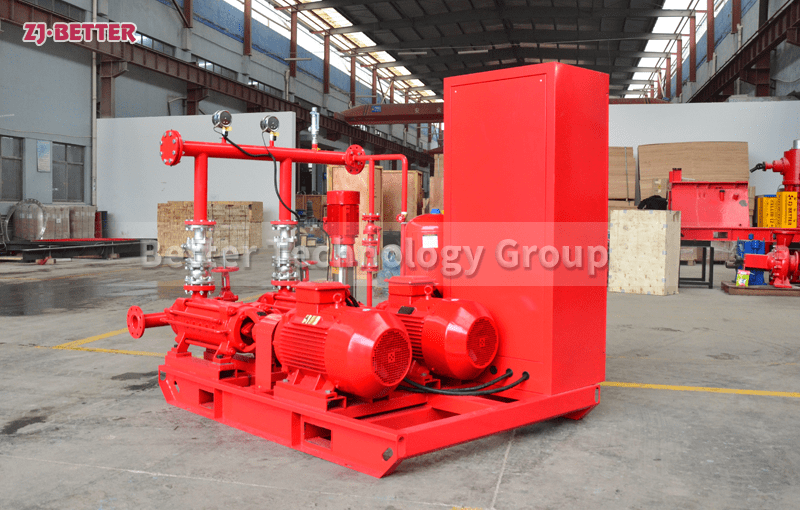

Multi-stage fire pump systems are high-performance equipment designed specifically for fire safety and emergency water supply. Known for their precise control and reliable performance, they are widely used in high-rise buildings, industrial plants, storage centers, airports, docks, and urban fire stations. They provide a continuous and stable high-pressure water supply in complex and ever-changing firefighting scenarios, ensuring sufficient water supply for fire suppression systems at critical moments. The design of these pump systems not only reflects the intelligent and automated trends in modern firefighting equipment, but also incorporates multiple technical advantages such as energy saving, stability, and ease of maintenance, providing a solid foundation for the long-term operation of firefighting systems. Multi-stage fire pump systems utilize a series-connected impeller design, which allows the water flow to accumulate energy at each stage, resulting in high head and high pressure output. These pump systems meet the stringent requirements of large buildings, long-distance water supply, and high-pressure sprinkler systems. Their core power supply is typically driven by a high-efficiency electric motor or diesel engine, and is equipped with an automatic switchover control system to automatically activate a backup power source in the event of a main power failure, ensuring continuous system operation. The pump body is constructed of high-strength cast iron or stainless steel, precision-machined, and dynamically balanced for superior pressure, vibration, and corrosion resistance. It maintains smooth, trouble-free operation even under long-term, high-load conditions. The system’s control unit, the intelligent core of the entire installation, features an advanced automatic monitoring and control panel that displays real-time operating parameters such as pressure, water flow, current, and voltage. Users can freely switch between manual, automatic, and remote control modes via a touchscreen interface. When the system detects a drop in water pressure or a fire alarm, the control system immediately initiates a command to automatically activate the primary or backup pump, restoring the water supply pressure to the set value in the shortest possible time. It also intelligently coordinates the operation of multiple pumps based on demand, minimizing energy waste and extending equipment life. The system’s pressure control is highly precise, utilizing variable frequency control technology to adjust output pressure in real time, perfectly matching the water supply flow rate to system requirements. This ensures stable output, whether for low-pressure inspections or high-pressure firefighting operations. This not only improves firefighting efficiency but also significantly reduces operating energy consumption, a key feature of modern energy-efficient firefighting systems. Multi-stage fire pump systems are designed with safety and redundancy in mind. They typically include a main pump, a backup pump, a pressure-stabilizing pump, and a surge tank. The pressure-stabilizing pump maintains the base pressure of the system’s pipeline network during non-fire conditions, preventing frequent starting and stopping of the main pump. In the event of a fire, the main and backup pumps automatically switch operation, creating a reliable dual-insurance mechanism. Furthermore, the system is equipped with automatic alarm and protection features. In the event of an abnormality such as overload, phase loss, overheating, low pressure, or water shortage, the control system immediately stops operation and issues an audible and visual alarm, preventing equipment damage and alerting personnel for prompt action. Another significant advantage of this fire pump system is its ease of installation and maintenance. The entire system utilizes a modular, integrated design and is fully assembled and commissioned before shipment. Users only need to connect the inlet and outlet pipes and power supply, significantly shortening the installation cycle. Regarding maintenance, the pump body and motor are split, facilitating disassembly and inspection. Key components such as bearings, seals, and impellers are constructed using international standards, ensuring high compatibility and ease of replacement. The system operates with low noise and vibration, and boasts excellent mechanical balance, making it ideal for installation in residential areas, high-rise basements, or other environments requiring high noise control. The multi-stage fire pump system is highly adaptable, allowing flexible configuration of flow and head parameters to suit building size and fire protection requirements. It supports parallel or series operation for multi-point water supply or zoned control, making it suitable for a variety of fire protection systems, including sprinklers, fire hydrants, water curtains, and water monitors. Optional special materials and high-temperature sealing components are available for industrial applications involving corrosive liquids or high-temperature media, further extending the system’s applicability and service life. Energy conservation and environmental protection are key highlights of this system. By incorporating variable frequency control technology and a high-efficiency motor drive, the system automatically adjusts pump speed based on real-time pressure demand, reducing inefficient energy consumption and achieving energy savings of over 30%. Furthermore, intelligent control logic automatically rotates the primary pump during multi-pump operation, balancing the operating time of each pump and preventing mechanical fatigue caused by prolonged high-load operation of a single pump, thereby extending the service life of the entire system. The performance and stability of multi-stage fire pump systems have been proven in numerous engineering projects. Whether in demanding environments such as large complexes, chemical parks, or airport terminals, they deliver continuous, sufficient, high-pressure water flow in the shortest possible time, reliably ensuring fire safety. Their powerful power output, highly intelligent control logic, robust mechanical structure, and energy-efficient operation make them a core component of modern building fire protection systems. In the overall design of fire protection systems, the application of multi-stage fire pumps not only demonstrates technological advancement but also embodies safety principles. They transform fire water supply from a passive response to a proactive defense, truly achieving the goal of “intelligent fire protection, instant water supply.” With the acceleration of urbanization and the expansion of building scale, fire safety standards are constantly improving. Multi-stage fire pump systems, with their exceptional reliability and forward-looking design, are becoming a key development direction in the future fire protection industry. Whether in new construction or retrofitting existing systems, they have earned the trust of users with their efficiency, safety, intelligence, and energy-saving features, making them an ideal choice for ensuring the stable operation of fire water supply systems.