Independent Diesel Fire Pump System – A Solid Guarantee for Fire Safety

The independently operated diesel fire pump offers powerful power and high reliability, automatically starting and continuously supplying water even during power outages, ensuring stable fire protection system operation. Featuring an energy-efficient design, intelligent control system, and durable construction, this pump is suitable for a variety of locations, including industrial, commercial, and high-rise buildings, providing a safe, efficient, and long-lasting fire water supply and an ideal solution for emergency fire response.

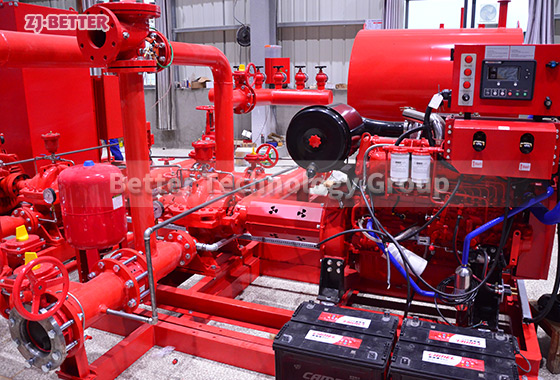

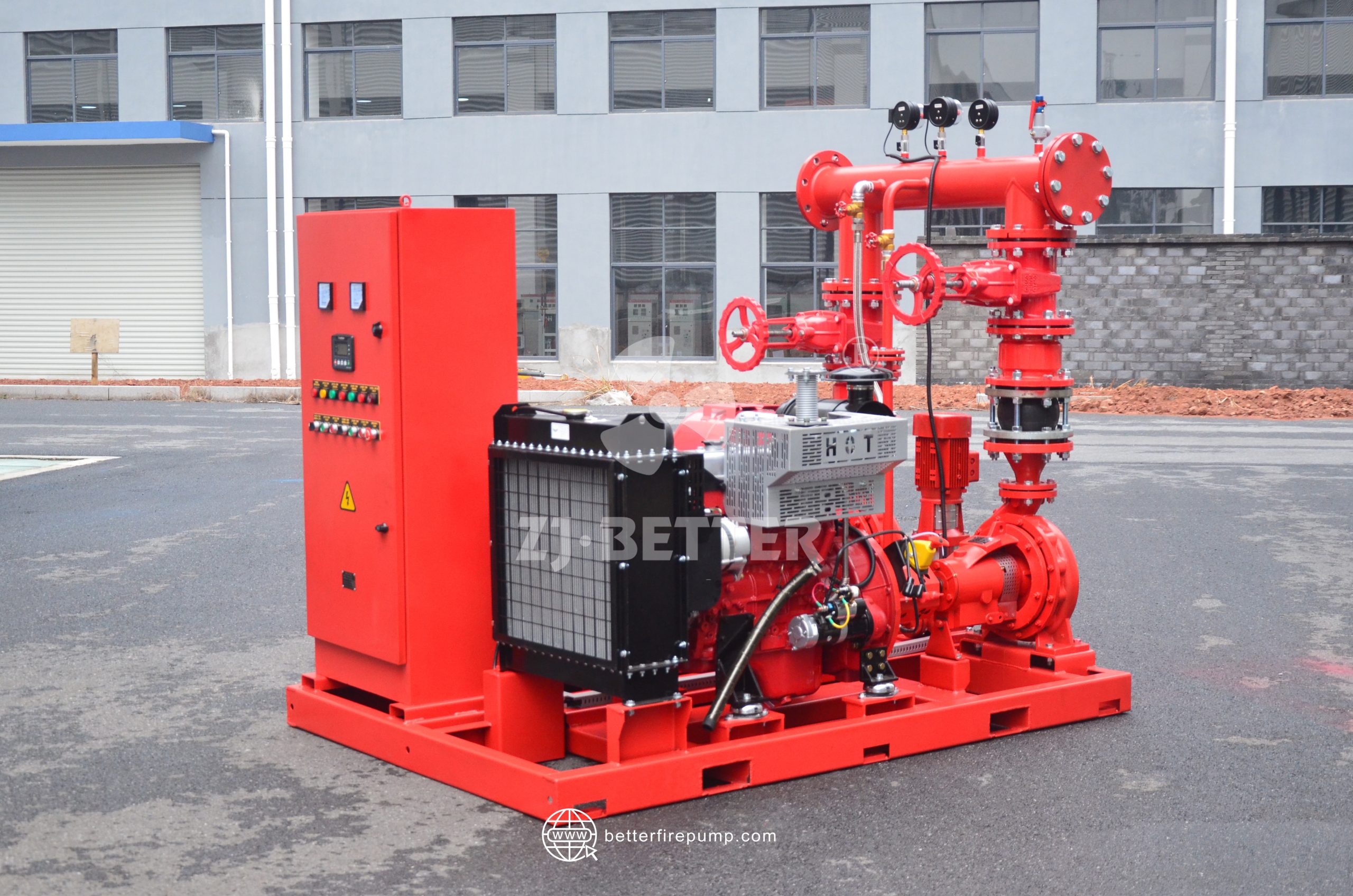

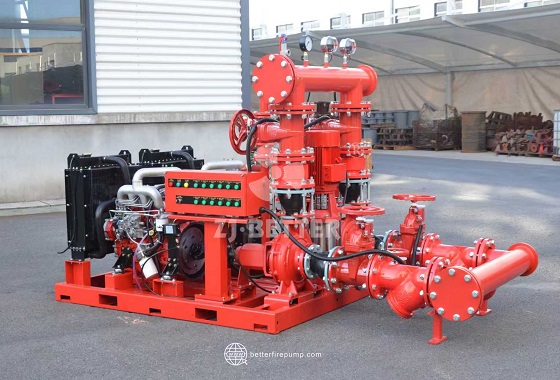

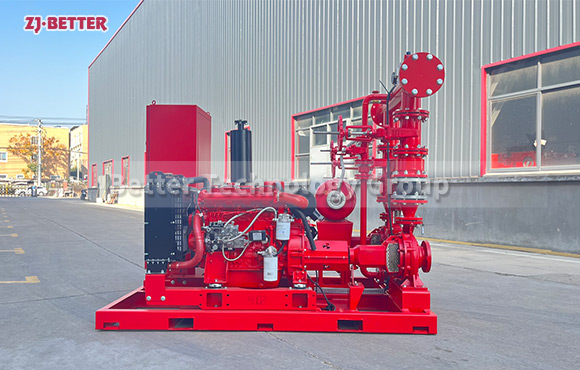

The standalone diesel fire pump system is a high-performance water supply device designed to handle a variety of complex firefighting environments. Powered by a diesel engine, it operates reliably even in power outages or power interruptions, providing reliable fire water supply for critical locations such as buildings, factories, oil depots, docks, power stations, storage areas, and high-rise buildings. The system’s greatest strength lies in its independence and efficiency, enabling it to start, operate, and supply water without relying on an external power grid. It is an indispensable core component of modern firefighting systems. The diesel fire pump system consists of a diesel engine, centrifugal pump, coupling, baseplate, fuel system, cooling system, exhaust system, electronic control system, and monitoring panel. Its precisely matched structural design and high-strength material construction achieve a perfect balance of high head, high flow rate, low noise, and high durability. Designed in accordance with international firefighting standards, it boasts excellent self-priming performance and long-term continuous operation. It can maintain stable water pressure in extreme weather conditions, ensuring water requirements for both initial firefighting and ongoing firefighting. One of the pump units’ most significant advantages is its independent operation. Even in the event of a power outage, a fire causing a power outage, or operating in an area without electricity, the diesel fire pump can automatically start and quickly resume operation, ensuring that the fire system’s water pressure remains constant, thereby preventing serious fire damage caused by water supply interruptions. The system utilizes an automatic control module, enabling fully automated detection, alarm, and activation. When the pipe network pressure drops below a set value, the diesel engine immediately starts and drives the pump to deliver water, eliminating the need for manual intervention and significantly improving the speed and reliability of firefighting response. The diesel fire pump unit offers exceptional performance, offering a wide range of flow and head parameters that can be flexibly customized to meet the fire protection design requirements of various buildings and industrial sites. The pump body is constructed of high-strength cast iron or stainless steel, offering excellent corrosion and wear resistance, ensuring stable performance even in water sources containing impurities. The dynamically balanced impeller ensures low vibration, low noise, and high efficiency during operation, extending the equipment’s service life. The engine utilizes internationally advanced combustion and cooling technologies, delivering powerful power and excellent fuel economy. It delivers stable speed and torque while maintaining low fuel consumption, achieving highly efficient energy conversion. The control system is one of the core technologies of this diesel fire pump. The intelligent electronic control panel integrates multiple monitoring and protection functions, including real-time display of parameters such as oil pressure, temperature, water temperature, speed, number of starts, battery charge, and operating time. It also features automatic alarms and safety shutdowns. If a system anomaly occurs, such as low oil pressure, high temperature, or an operating timeout, the controller immediately issues an alarm and automatically initiates safety measures to prevent equipment damage. Users can also use the remote control interface for remote monitoring and data transmission, facilitating centralized management and maintenance of the fire protection system. The diesel fire pump system was designed with ease of use and maintenance in mind. Its modular design facilitates installation and transportation, and its shock-resistant base effectively reduces vibration transmission during operation and improves overall stability. The fuel tank and exhaust system are strategically located for easy refueling and exhaust, extending the engine’s service life. The system offers a long maintenance cycle, versatile accessories, and low ongoing operating costs, making it suitable for long-term, continuous use in industrial and commercial environments. Independently operated diesel fire pumps not only offer superior performance but also exceptional safety. The system supports both manual and automatic start-up modes, enabling rapid switching in emergencies and ensuring immediate fire water supply operation regardless of the operating conditions. Its cooling system utilizes a closed-loop water cooling system, ensuring the engine maintains an ideal temperature even under prolonged high loads, preventing failures caused by overheating. The exhaust system is designed to meet environmental standards, effectively reducing emissions and environmental pollution, embodying an energy-saving and environmentally friendly design philosophy. Compared to electric fire pumps, diesel fire pump systems offer significant advantages in independence and reliability. Electric fire pumps are limited by the power supply. In the event of a power outage, the time required to switch to backup power can cause a drop in fire water pressure. However, diesel fire pumps, with their self-sufficient power system, can start up quickly and provide a stable, high-pressure water supply, making them particularly suitable for locations with unstable or no power. Furthermore, diesel fire pumps can be combined with electric pumps and pressure-stabilizing pumps to form a combined fire pump system. Through a control system, automatic switching and coordinated operation are achieved, further enhancing the safety and flexibility of the entire fire protection system. This system has a wide range of applications in fire protection projects, providing a powerful emergency water supply in high-risk areas such as urban complexes, hospitals, subway stations, tunnels, airports, and docks, as well as oil depots, chemical plants, and power stations. It provides sufficient water pressure to support the coordinated operation of sprinkler and fire hydrant systems in the early stages of a fire, helping to quickly control the spread of a fire and gain valuable time for rescue efforts. Independently operating diesel fire pumps are not just equipment but also a safety mechanism. Combining mechanical reliability with intelligent control technology, they provide an efficient, stable, and sustainable power solution for modern fire protection systems. Their superior performance, high degree of automation, excellent adaptability, and strong operational independence make them the most trusted water supply core in modern building fire protection design. This diesel fire pump system will continue to play a key role in the future development of intelligent fire protection systems, with continuous technological optimization, energy conservation, environmental protection, and digital monitoring, providing even stronger support and assurance for global fire safety.