Diesel Fire Pump Set with Automatic Control Panel: Round-the-Clock Protection for Your Fire Safety

ZJ-BETTER diesel fire pump set with advanced automatic control system ensures 24/7 fire safety in high-rises, petrochemical plants, and industrial sites. Smart monitoring, high efficiency, and compliance with ISO, CE, and UL standards.

In modern buildings and industrial facilities, the reliability of fire protection systems is crucial. The ZJ-BETTER diesel fire pump set, equipped with an advanced automatic control system, stands out as the ideal solution for responding to emergency fire incidents. Designed especially for environments with unstable or unavailable mains power, it guarantees a continuous and powerful water supply under all conditions.

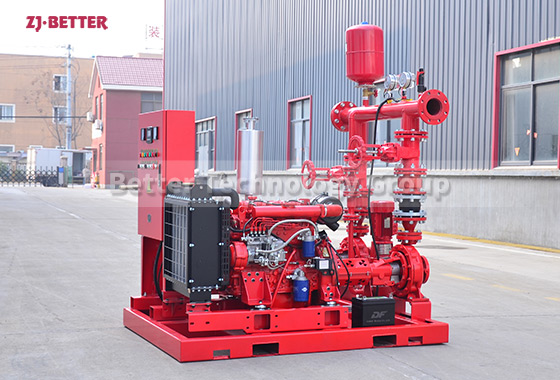

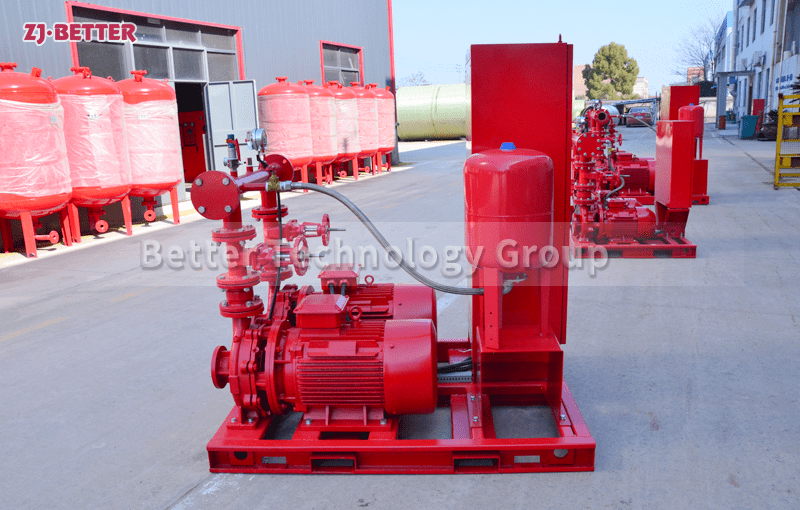

This integrated diesel-powered fire pump package consists of a diesel engine, fire pump, coupling, base frame, fuel tank, batteries, control cabinet, instrumentation, intake and exhaust systems, and an intelligent control panel. The automatic control system is at the heart of this unit, offering remote start, automatic switchover, fault alarms, and real-time operational monitoring — all contributing to high efficiency and automation.

ZJ-BETTER’s automated diesel fire pump set is engineered to meet the demands of a wide range of applications, including high-rise buildings, petrochemical plants, industrial zones, and warehouse complexes — all of which require immediate fire response capability independent of the mains power supply. The unit utilizes a high-performance diesel engine, capable of one-button emergency startup to deliver high-pressure, high-flow water instantly, ensuring timely intervention and supporting fire suppression operations effectively.

The integrated control system adopts a microcomputer-based chip controller and can be connected to a fire control center or building management system (BMS). It provides real-time monitoring of key parameters such as pump status, battery voltage, fuel level, and coolant temperature. In the event of anomalies — such as startup failure, low fuel level, or overheating — the system issues audible and visual alarms while logging fault codes for quick troubleshooting.

Moreover, this fire pump set is compact in structure, easy to install and transport, and all components are treated with anti-corrosion coatings, making it suitable for both indoor and outdoor environments. Maintenance costs and failure rates are significantly reduced. All ZJ-BETTER diesel fire pump units are manufactured to ISO and CE standards, with certain models complying with UL and FM certifications to meet global compliance requirements.

Choosing the ZJ-BETTER diesel fire pump with automatic control is not only a strategic upgrade to your fire protection system but also a critical investment in safeguarding lives and property. We provide customized configuration options and comprehensive after-sales support. Please contact us for detailed technical specifications and pricing.