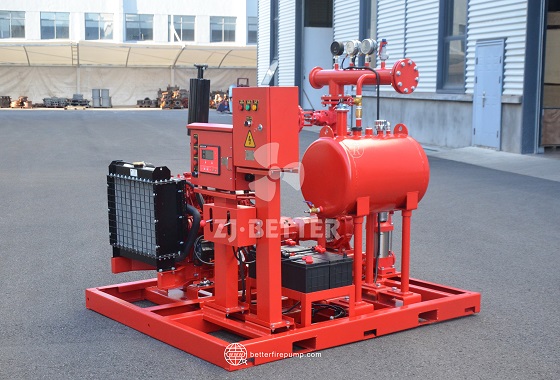

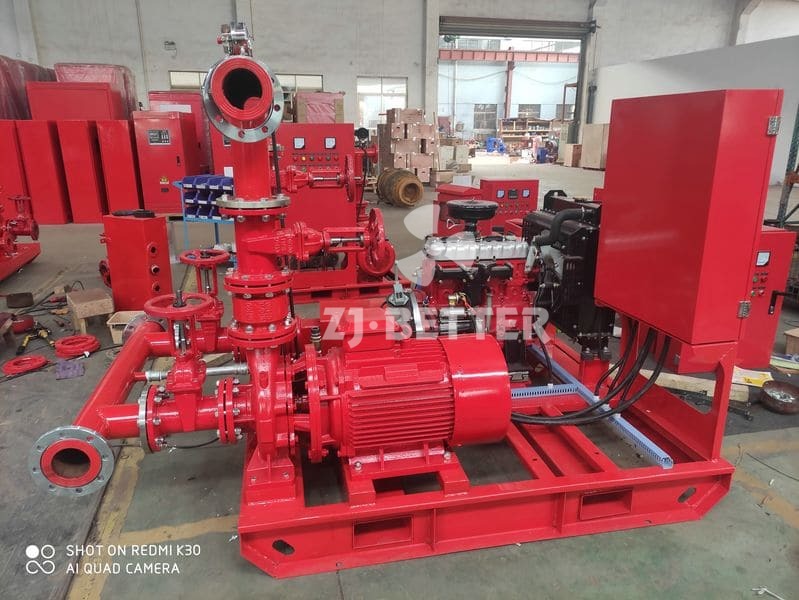

EEJ-ISW Fire Pump Set (inspection cabinet + control cabinet)

The complete fire pump system consists of pumps, drivers, controllers and accessories installed on a universal base, and is suitable for fire water supply and emergency water supply in warehouses, storage yards, airports, petrochemicals, liquefied gas in power plants, textiles, ships, oil tankers, etc. This pump set is ideal for firefighting or voltage stabilization in houses or small buildings. We customize it to NFPA 20 and UL standards.

The fire pump refers to the clean water pump used for fire water supply, and the processing medium temperature is lower than 80 degrees and is not corrosive. The pump set is the joint operation of multiple fire pumps to ensure the quantity and stability of the water supply. The electric motor fire pump group adopts multiple fire pumps powered by electric motors. The general fire water supply environment is equipped with one electric and one diesel fire pump as the reserve water pump to ensure sufficient emergency water consumption. The main components of the electric motor fire pump group are the motor and the pump body. The pump body is subdivided into the pump casing, impeller, pump shaft, bearing, coupling, sealing form, water lift pipe, etc. The specific fire pump model is determined according to the environment and performance requirements. According to the material quotation required by the customer, accurate selection is conducive to on-site use and reduces failure problems.