High-Efficiency Small Diesel Engine Unit: Powerful Drive for Portable Fire Pumps

High-performance small diesel engine power unit designed for portable fire pumps, featuring strong power output, reliable cold start, excellent fuel efficiency, and long service life. Ideal for firefighting, emergency drainage, and industrial water supply with stable performance, easy maintenance, and adaptability to harsh environments.

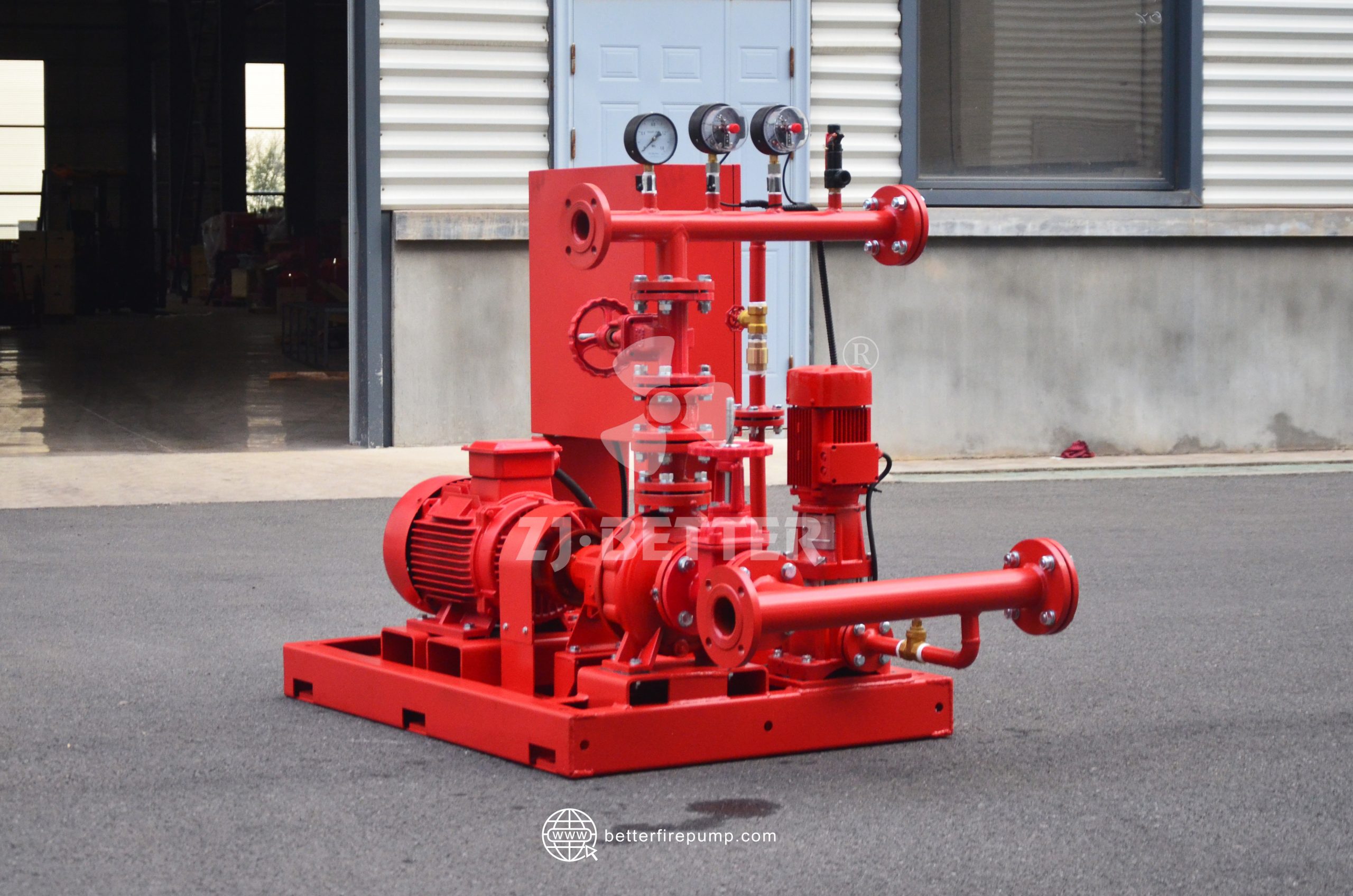

In modern fire protection systems, portable fire pumps are widely used in construction sites, warehouses, ports, oil depots, chemical plants, rural fire fighting, and water conservancy emergency rescue due to their flexibility and rapid emergency response. At the heart of these systems, small diesel engine power units play a crucial role. High-efficiency small diesel engine power units, with their strong output performance, reliable starting capability, excellent fuel economy, and outstanding adaptability, are ideal drive sources for portable fire pumps. These diesel power systems are specifically designed to provide immediate power in sudden fires and complex environments, ensuring that fire-fighting equipment can achieve maximum effectiveness at critical moments. The greatest advantage of small diesel engine power units lies in their perfect balance between high efficiency and high reliability. By employing advanced fuel injection technology and air supercharging design, the engine can still output stable high torque power while maintaining low fuel consumption. Whether in low temperature, oxygen-deficient, or high temperature and humidity environments, the diesel engine can maintain smooth starting and continuous operation, ensuring that the fire pump system can be immediately put into use in emergencies. This characteristic is particularly critical for emergency fire operations, as any delay in starting can lead to a decrease in fire-fighting efficiency or even the risk of escalation. This power unit boasts excellent cold-start performance, equipped with a high-pressure fuel injection system and preheating device, ensuring rapid start-up even in sub-zero temperatures without the need for external power or auxiliary equipment. In terms of power output, the small diesel engine power unit utilizes a high-pressure common rail fuel system and a high-efficiency combustion chamber structure, resulting in more complete combustion and stronger power. The engine’s maximum power output can meet the operational requirements of various types of fire pumps, from portable single-person operated pump sets to medium-sized high-lift pump systems, providing stable power supply. Simultaneously, its torque curve is smooth, and its low-speed output capability is strong, meaning that the engine can maintain continuous and stable operation during prolonged, high-pressure water supply operations, without performance degradation due to load fluctuations. This continuous output characteristic is crucial for fire pump systems, ensuring continuous water pressure and thus guaranteeing the stability and coverage of fire suppression spray. Furthermore, this diesel engine power unit was designed with lightweighting and portability in mind. By optimizing the cylinder block structure, using high-strength aluminum alloy materials, and employing a compact cooling system, the overall weight has been significantly reduced while maintaining high mechanical strength. This improvement makes the portable fire pump lighter and easier for a single person to carry and quickly deploy, making it ideal for fire emergency tasks requiring flexible mobility. For example, in scenarios such as rural fires, mountain fires, and ship firefighting, personnel can quickly carry the pump to the scene, connect it to a water source, and immediately begin operations. Reliability is the lifeline of firefighting equipment, and the small diesel engine power unit excels in this regard. The core engine components undergo high-precision machining and rigorous heat treatment, resulting in extremely high wear resistance and fatigue resistance. The crankshaft uses an alloy steel forging structure, combined with high-precision balancing, ensuring smooth operation and low vibration, significantly extending its service life. The cooling system uses forced air cooling or water cooling, combined with an intelligent temperature control device, which automatically adjusts cooling efficiency according to the load to prevent engine overheating. The lubrication system is equipped with a high-efficiency oil circulation device, ensuring low-friction operation even under high loads, effectively reducing energy consumption and wear. In terms of operation and maintenance, this diesel engine power unit is designed with user-friendliness in mind and is easy to operate. Manual and electric start systems can be flexibly selected according to needs, allowing users to easily complete start-stop operations. The control panel integrates functions such as fuel level display, tachometer, and alarm indicators, monitoring engine operating status in real time to ensure equipment safety. The modular design makes maintenance more convenient; common components such as filters, fuel injectors, and oil pumps are easy and quick to replace, significantly reducing maintenance time and costs. Compared to gasoline engine power units, diesel engines have a longer service life and a lower failure rate, making them suitable for frequent, high-intensity use. High fuel efficiency is another major highlight of this power unit. Diesel fuel itself has a high calorific value, and combined with a high-pressure injection system, the combustion process is more complete, significantly improving fuel conversion efficiency. Under the same power output conditions, diesel engines can reduce fuel consumption by approximately 20%-30% compared to traditional gasoline engines. This not only reduces operating costs but also lowers emissions of carbon dioxide and unburned hydrocarbons, meeting modern environmental protection requirements. Some models can also be equipped with a low-noise silencing system and emission purification device to further reduce noise and emission pollution, making them suitable for urban fire protection and industrial applications with stringent environmental requirements. This diesel engine power unit also has excellent environmental adaptability. Whether in high-altitude areas, deserts, humid coastal regions, or cold mountainous areas, the engine can automatically adjust the fuel injection quantity and combustion efficiency through an adaptive fuel control system, thereby ensuring stable output. The air filtration system employs a multi-stage filtration design, effectively preventing dust and sand particles from entering the combustion chamber, making it suitable for long-term use in dusty, highly polluted environments. The fuel system is made of corrosion-resistant materials, resisting damage from low-quality diesel or water-containing fuels, extending the overall lifespan of the engine. In terms of safety, the diesel engine power unit is equipped with multiple protection mechanisms, including low oil pressure alarm, over-temperature protection, and overspeed shutdown. Once an abnormal operating condition is detected, the system automatically cuts off the fuel supply and sounds an alarm to prevent equipment damage or fire risks. Furthermore, some models support remote monitoring and automatic start-stop control, and can be linked with fire control systems to achieve unattended operation. This intelligent control technology enables the equipment to have a higher level of automation and response speed in emergency fire protection systems. Besides its core applications in fire protection, this small diesel engine power unit is also widely used in emergency drainage, agricultural irrigation, industrial water supply, and engineering backup power, demonstrating powerful versatility and wide adaptability. Its modular interface design allows for easy connection to various pumps or generators, forming a multi-purpose power system, thus providing users with greater flexibility and investment value. In summary, the high-efficiency small diesel engine power unit, with its superior power output, excellent fuel economy, reliable starting performance, outstanding durability, and intelligent control characteristics, has become an indispensable core component in portable fire pump systems. It not only ensures the efficient operation of fire-fighting equipment in critical moments but also provides users with an economical, environmentally friendly, and reliable power solution. Whether in fire emergency response, industrial safety, or daily backup applications, this high-performance diesel engine power unit has won widespread market recognition and trust for its stable performance and long-term durability, making it an ideal power choice for modern fire pump systems.