Discover the EDJ Fire Pump for superior performance

Experience unmatched performance and reliability with the EDJ Fire Pump.

Designed to meet the highest standards of fire protection, our pump offers exceptional functionality and dependability.

Whether for residential, commercial, or industrial applications, the EDJ Fire Pump provides the peace of mind you need for effective fire prevention and suppression. Trust in our advanced technology and ensure the safety of your property with the EDJ Fire Pump.

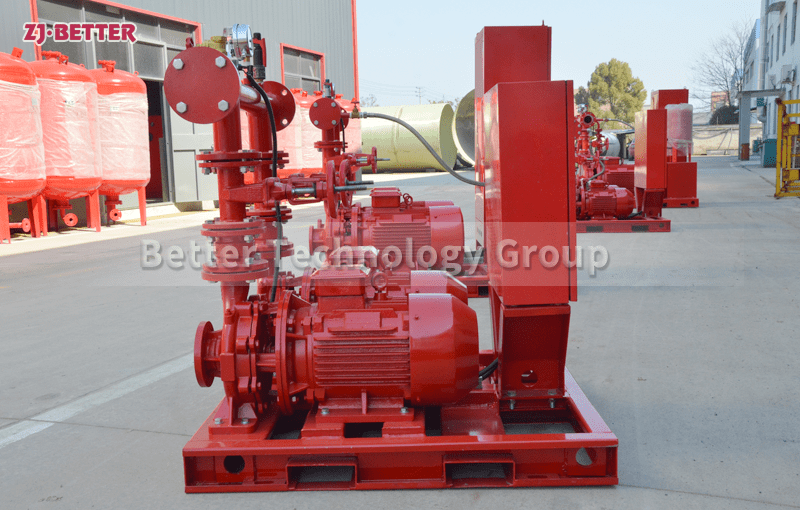

Electric pump system: We offer a variety of electric pumps, including single-stage pumps, horizontal split-case pumps, end-suction pumps, and multi-stage pumps, available in cast iron or stainless steel construction. The pumps are equipped with efficient copper impellers to ensure exceptional performance.

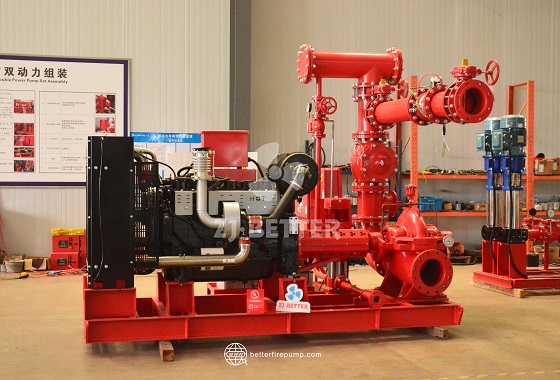

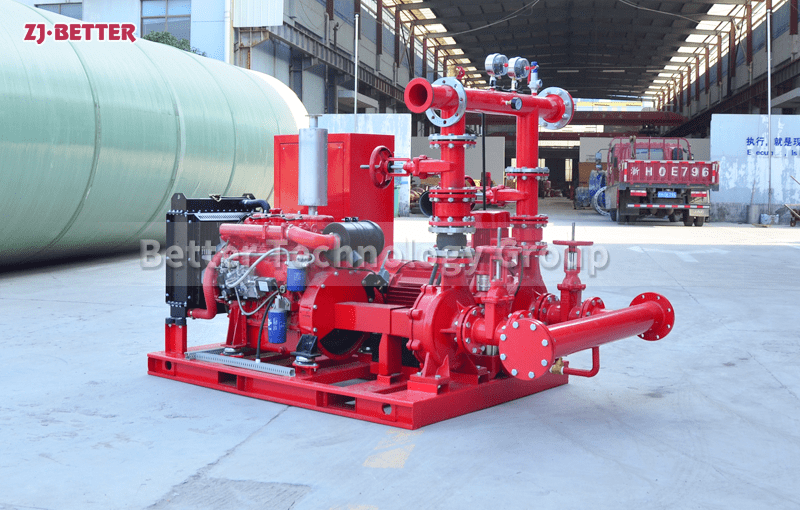

Diesel engine pump system: With the same flow capacity as the electric pumps, the diesel engine pump system is integrated with high-flexibility couplings or universal joints to form a complete fire pump unit. Additionally, the system includes components such as fuel tanks, water tanks, fans, and control panels to provide comprehensive reliability.

Pressure stabilizing pump system: Whether in horizontal or vertical configuration, our pressure stabilizing pump system delivers lower flow rates but higher head pressure, ensuring a stable water pressure for the fire protection system.

Advanced control panel: Equipped with an intelligent control panel, the system enables automatic control of the electric pumps, diesel engine pumps, and pressure stabilizing pumps. The control panel features overload and overcurrent protection, ensuring the safe and stable operation of the system.