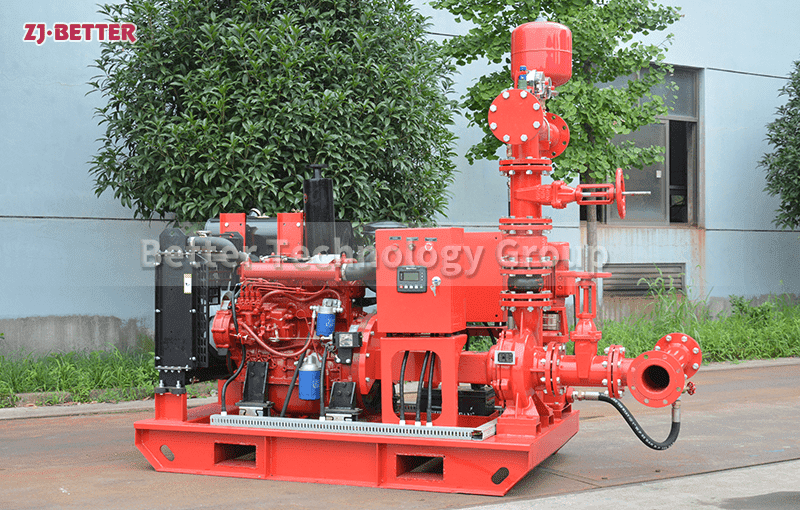

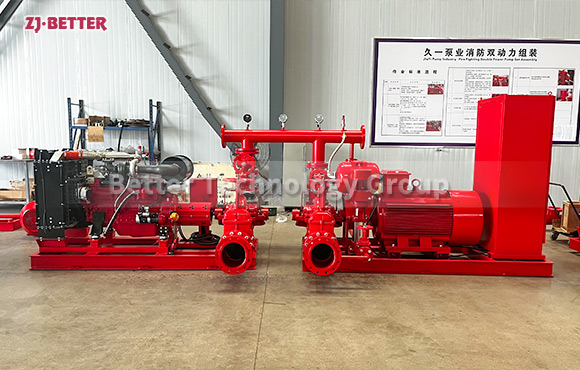

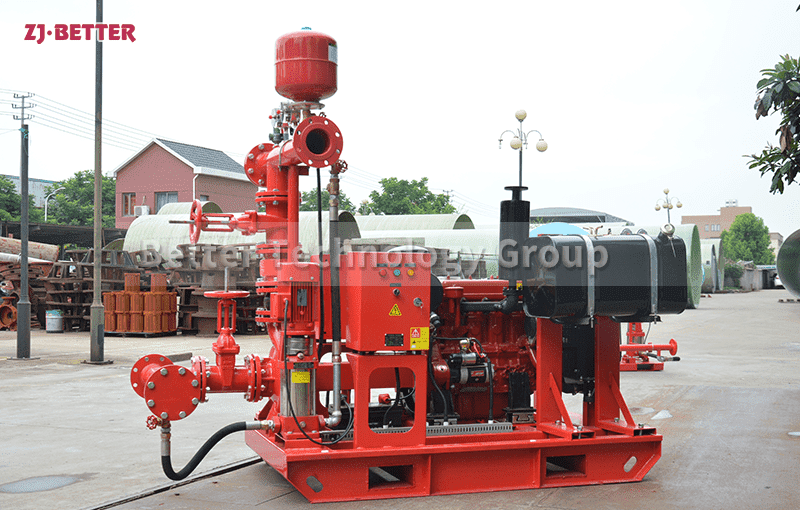

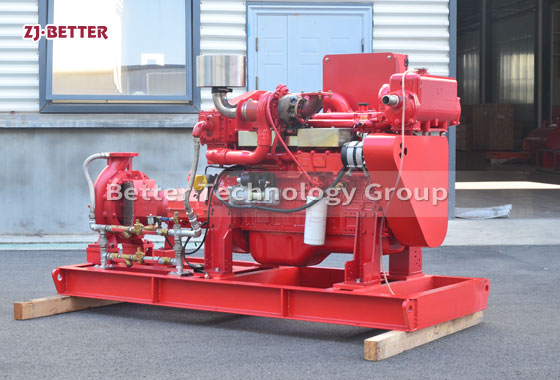

High Head Vertical Fire Pump for Direct Suction from Fire Water Tanks

High-lift vertical fire pumps are designed for direct water supply to large fire water tanks. They feature high lift output, rapid start-up, stable operation, and continuous water supply capability, making them suitable for high-rise buildings and industrial fire protection systems, thus improving the overall safety of fire water supply.

This high-lift vertical fire pump is a core fire-fighting water supply device specifically designed for direct suction water supply conditions in large fire water tanks, reservoirs, and underground fire water sources. Its overall structure adopts a vertical layout and long shaft drive, allowing the pump body to penetrate deep into the water tank for stable water intake. This effectively avoids the cavitation, starting difficulties, or unstable water supply problems caused by the limited suction head of traditional horizontal pumps. It can quickly establish stable water pressure the moment the fire-fighting system is activated, meeting the stringent requirements of high lift and continuous water supply capacity for large buildings and industrial fire protection projects. In terms of hydraulic design, this vertical fire pump fully incorporates direct suction conditions. By optimizing the number of impeller stages and the flow channel structure, the water flow smoothly transitions between each impeller stage, significantly improving the overall head output capacity while maintaining good hydraulic efficiency. Even under high-lift operation, it can still stably output the rated flow rate, ensuring sufficient water pressure for the sprinklers and fire hydrants at the end of the fire-fighting network. The core components of the pump body are made of high-strength materials, possessing excellent pressure resistance and impact resistance. This allows it to withstand instantaneous pressure fluctuations and long-term high-load operation in fire protection systems, significantly improving overall equipment safety and service life. The vertical structure maintains a reasonable distance between the motor and the water source, preventing adverse effects on the drive system from prolonged immersion or damp environments. Simultaneously, the long shaft, through multi-point support and precise coaxial correction design, effectively reduces vibration and sway during operation, ensuring stable and reliable operation of the pump unit under high speed and high head conditions. This product excels in starting performance. The dedicated drive motor features high starting torque and fast response speed, allowing it to quickly start working upon receiving a fire alarm start signal, even after long periods of standby, avoiding delays or failures that could affect the overall response efficiency of the fire protection system. The sealing system employs a mature and reliable combination of mechanical seals and auxiliary seals, ensuring sealing performance while also considering wear resistance and high-temperature resistance. This effectively prevents media leakage, ensuring the fire pump maintains good working condition even with frequent switching between long periods of standby and emergency operation. This high-lift vertical fire pump has significant advantages in adapting to complex water sources. It can operate stably in fire pools, water tanks, or underground water storage facilities, and has a strong adaptability to water level changes. Even with large water level fluctuations, it can maintain continuous water intake and stable water supply, avoiding water supply interruptions due to cavitation or air intake, and providing higher safety redundancy for large-scale fire protection systems. The overall structure was designed with practical installation and maintenance needs in mind. The modular component layout makes on-site installation more convenient, and the long shaft section can be flexibly configured according to the depth of the water pool, reducing non-standard modification costs. It also provides good conditions for later maintenance, shaft adjustment, and replacement of vulnerable parts, effectively reducing long-term operation and maintenance difficulty and costs. In terms of system integration, this vertical fire pump can work in conjunction with fire control cabinets, pressure control devices, and automatic inspection systems, realizing multiple operating modes such as automatic start, manual control, and remote linkage. When the fire protection system detects a pressure drop or fire signal, the equipment can quickly respond and enter a stable operating state. It also has multiple protection functions such as overload, phase loss, and overheating protection, further improving the operational reliability of the entire fire water supply system. To meet the needs of various large-scale fire protection projects, this high-lift vertical fire pump can be flexibly combined in terms of flow rate, head, shaft length, and interface specifications, making it widely applicable to various scenarios such as large commercial complexes, high-rise residential buildings, industrial parks, warehousing and logistics centers, power facilities, and municipal fire protection projects. Each unit undergoes rigorous performance and quality testing before leaving the factory, including head and flow rate testing, continuous operation testing, and vibration and noise testing, ensuring that it can stably meet the stringent requirements of fire protection systems for high-lift direct-suction water supply in actual use. In summary, this high-lift vertical fire pump, with its excellent direct-suction water supply capacity, stable and reliable high-lift performance, good environmental adaptability, and convenient installation and maintenance, has become an important piece of equipment in large fire water tank supply systems to ensure fire safety, providing solid support for building a safe, durable, and efficient fire water supply system for various engineering projects.