High-Efficiency, Low-Noise, and Low-Maintenance Electric Fire Pump Solution

Discover a high-efficiency, low-noise, and low-maintenance electric fire pump designed for superior firefighting performance. Ideal for commercial, industrial, and high-rise applications with advanced control systems and energy-saving features.

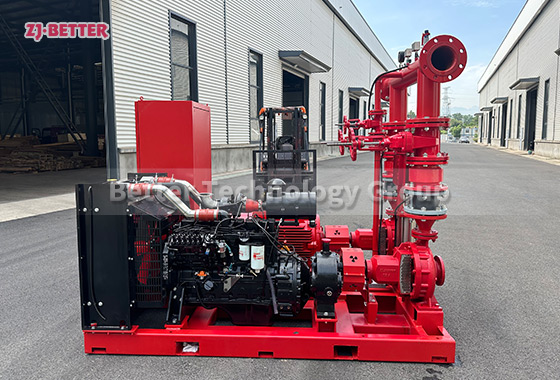

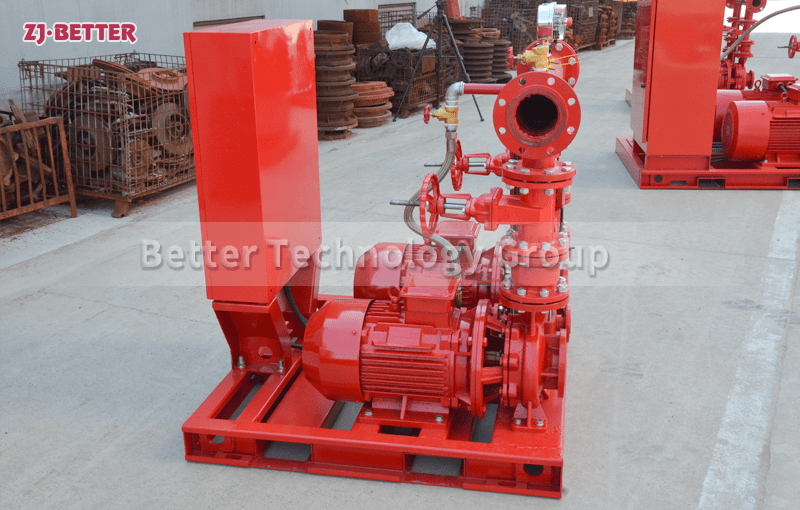

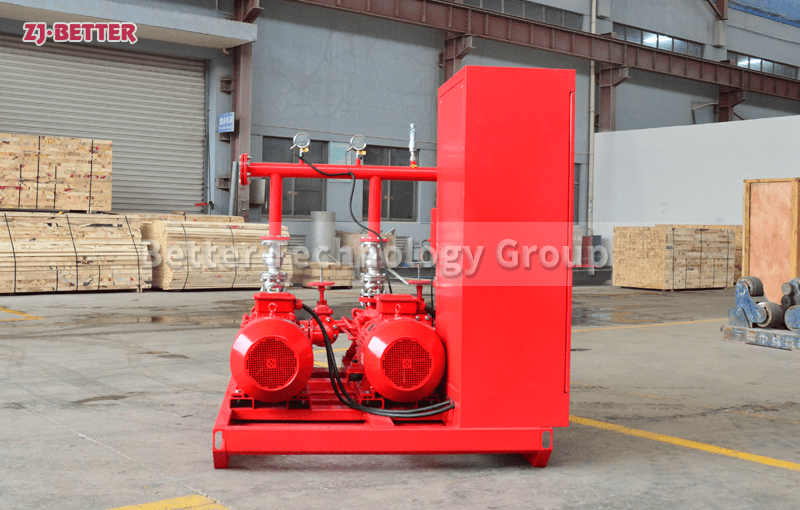

The electric fire pump solution featured here is a high-performance, precision-engineered system designed to meet the most rigorous demands of modern firefighting applications. Built for high efficiency, low noise, and minimal maintenance, this fire pump is ideal for installations in commercial buildings, industrial facilities, high-rise structures, warehouses, chemical plants, airports, and municipal fire protection systems. The unit integrates a robust horizontal multistage centrifugal pump with a powerful electric motor, offering superior pressure stability and water delivery rates across a wide range of operational conditions. One of the most significant advantages of this electric fire pump is its exceptional hydraulic performance. The pump is designed with advanced computational fluid dynamics to ensure optimal flow paths and minimal hydraulic losses. The multistage design provides high head capabilities, making it ideal for systems requiring long-distance water delivery or vertical lifts in high-rise applications. Additionally, the internal components, such as precision-cast impellers and wear-resistant diffusers, are manufactured using high-grade stainless steel or cast iron with anti-corrosion coatings, ensuring prolonged life in harsh environments and compatibility with various water qualities. Energy efficiency is a core feature of this pump system. The electric motor is designed to operate at high efficiency levels (IE3 or above), reducing energy consumption and operating costs over the long term. The alignment between the motor and pump shaft is optimized to minimize mechanical losses, and optional variable frequency drives (VFDs) can be incorporated to further enhance energy savings by adjusting pump speed according to system demand. This not only reduces electricity bills but also contributes to lower carbon emissions, making it an environmentally responsible choice. Noise reduction is another critical feature that makes this pump ideal for indoor or noise-sensitive installations. The motor runs with low vibration due to dynamic balancing and precision alignment, while the pump casing and internal flow channels are acoustically optimized to minimize turbulence and cavitation noise. As a result, the system operates quietly even under full load, ensuring compliance with occupational noise standards and creating a more comfortable environment for nearby personnel. Maintenance requirements are minimal thanks to the system’s smart design and component durability. The electric motor requires less frequent servicing compared to diesel-driven counterparts, and the pump’s bearings are lubricated for extended intervals, reducing the need for manual intervention. The mechanical seals are made from premium materials that resist wear and leakage, extending service intervals and ensuring leak-free operation. In addition, the pump’s modular construction allows for easy access to internal parts during inspection or repairs, cutting down downtime and simplifying routine maintenance procedures. The integrated control cabinet enhances the system’s reliability and usability. It features advanced protection functions including overload, over-voltage, phase failure, and short-circuit protection, ensuring safe and stable operation at all times. The control panel includes intuitive indicators, status lights, and optional PLC or touchscreen interfaces for real-time monitoring of pressure, flow rate, motor status, and alarm notifications. Remote control and monitoring capabilities can be added to meet the needs of modern smart building systems or remote fire protection stations. From a safety and compliance perspective, the electric fire pump unit meets or exceeds international firefighting standards such as NFPA 20, EN12845, and GB6245. It has undergone rigorous performance and pressure testing to ensure that it delivers consistent and reliable performance during emergency scenarios. The system starts automatically upon receiving a signal from fire protection sensors, such as sprinklers or hydrant systems, ensuring rapid response and sufficient water pressure for firefighting teams or automatic suppression devices. Installation is straightforward due to the unit’s compact footprint and integrated skid-mounted base. The entire assembly is factory-tested before delivery, reducing commissioning time on site. All components are arranged logically and labeled clearly to facilitate installation and piping connections. Optional accessories such as pressure tanks, backflow preventers, check valves, and flow meters can be configured based on customer requirements or site-specific standards. The unit’s rugged design and anti-vibration base frame make it suitable for seismic zones or high-vibration industrial settings. The corrosion-resistant paint coating and stainless-steel fasteners provide durability against outdoor exposure or chemical-laden atmospheres. Moreover, the system can be customized with weatherproof or explosion-proof enclosures for use in special environments such as oil refineries, marine terminals, or offshore platforms. Operational flexibility is further enhanced by its ability to work in dual or standby configurations. The electric fire pump can be paired with a diesel backup pump or jockey pump for pressure stabilization and redundancy, ensuring uninterrupted protection even in case of power outages or component failure. This dual redundancy design is especially valued in mission-critical facilities where downtime is not an option. Customization options include pump flow rates ranging from 10 GPM to over 5000 GPM, discharge heads from 30 to 300 meters, and power ratings tailored to site needs. Customers can specify horizontal or vertical pump orientation, material grades, motor insulation class, and additional monitoring sensors for vibration, temperature, or seal leakage. These flexible configurations enable the system to be tailored precisely for local regulations, climate conditions, and infrastructure constraints. In summary, this high-efficiency, low-noise, and low-maintenance electric fire pump solution combines precision engineering, modern control systems, energy-saving design, and robust construction to deliver superior firefighting performance in demanding applications. Its reliability, ease of use, and adaptability make it an ideal choice for contractors, facility managers, fire protection engineers, and developers seeking a long-term, high-value fire pump solution that performs flawlessly when it matters most.