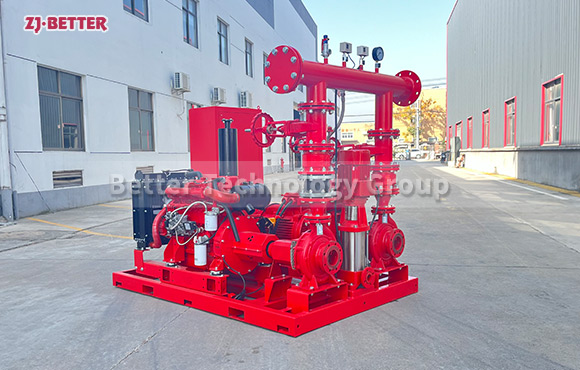

Heavy Duty Direct Coupled Horizontal Fire Centrifugal Pump

This highly efficient and durable horizontal motor-driven centrifugal fire pump features an optimized hydraulic design and high-strength construction, offering stable flow output, low vibration, high starting reliability, and the ability to operate under high load for extended periods. It is suitable for industrial plants, high-rise buildings, and municipal fire water supply systems.

This product is a heavy-duty, direct-drive horizontal centrifugal fire pump, specifically designed for fire water supply systems requiring extremely high reliability, stability, and continuous operation capabilities. The overall structure utilizes a horizontal single-stage centrifugal pump directly coupled to the motor, resulting in a short power transmission path and low energy loss. This ensures high-efficiency output while effectively reducing operating vibration and mechanical wear. It is particularly suitable for fire protection applications in industrial plants, high-rise buildings, warehousing and logistics centers, energy facilities, and municipal fire hydrant networks, where long-term standby and instantaneous high-intensity startup in emergency situations are required. The hydraulic design of this fire pump fully considers the specific requirements of fire fighting conditions. By optimizing the impeller profile and flow channel structure, the pump maintains stable hydraulic performance within the rated flow and head range. Even under high-load continuous operation, it ensures stable flow output and minimal pressure fluctuations, providing continuous and reliable fire water support to the end of the fire protection network. The pump body and key flow-through components are made of high-strength wear-resistant materials, possessing excellent impact resistance and corrosion resistance, enabling long-term operation under various water quality conditions, effectively extending the overall service life of the equipment and reducing maintenance frequency. The direct-drive motor structure is one of the significant advantages of this product. Compared to traditional coupling connections, the direct-drive design reduces intermediate transmission links, avoiding efficiency degradation and failure risks caused by misalignment or coupling wear. The overall structure is also more compact, requiring less space, facilitating flexible layout in projects with limited pump room space, and benefiting the overall planning and installation of the fire protection system. The motor selection is fully matched to the fire pump operating conditions, possessing high starting torque and excellent overload capacity. It can quickly enter a stable operating state under complex conditions such as power switching and emergency startup, ensuring uninterrupted fire water supply and preventing pressure drops, thus gaining valuable time for initial fire fighting. This horizontal centrifugal fire pump also demonstrates outstanding structural strength. The pump shaft is manufactured using high-precision machining processes and undergoes rigorous dynamic balancing verification. It maintains excellent shaft system stability even under high-speed operation. Combined with high-quality bearings and a reliable lubrication design, it effectively reduces operating noise and vibration levels, ensuring stable and reliable operation even during long-term high-load operation. The sealing system adopts a mature structural design suitable for fire fighting conditions, balancing sealing reliability and ease of maintenance. This ensures operational safety while reducing the risk of water leakage and downtime due to seal failure, further enhancing the reliability of the entire fire fighting system. Considering the characteristics of fire fighting equipment – ”standby during normal times, high-intensity operation during emergencies” – this product fully considers the practical need for low starting frequency but guaranteed success at critical moments during the design phase. Through reasonable structural redundancy and strict manufacturing process control, the equipment maintains excellent starting performance even after long periods of inactivity, preventing problems such as corrosion and jamming from affecting emergency use. The pump body interface dimensions and installation form comply with conventional fire fighting pipe network standards, facilitating quick connection to existing systems, reducing on-site modification work, and improving project implementation efficiency. It also provides convenience for future system upgrades and maintenance. In terms of operating performance, this fire fighting centrifugal pump has excellent efficiency curve characteristics, maintaining high hydraulic efficiency at different operating points, effectively reducing unit water supply energy consumption. This meets the high safety requirements of the fire fighting system while also considering energy saving needs during daily testing and drills. The overall equipment structure design follows the principle of easy maintenance; key components are reasonably arranged, and there is ample maintenance space. Routine inspection and maintenance operations can be completed without complex disassembly, helping to reduce the workload of maintenance personnel and the total life cycle cost of the system. The external structure is robust and durable, and the surface protection treatment meets the requirements of fire pump room environments, allowing for long-term use in complex conditions such as humidity, high temperature, or dust without affecting performance. Overall, this heavy-duty, direct-drive horizontal centrifugal fire pump demonstrates significant advantages in structural reliability, operational stability, hydraulic performance, and ease of maintenance. It is an ideal choice for standard fire fighting systems and demanding industrial fire fighting projects, providing continuous, stable, and sufficient fire fighting water supply at critical moments, and providing a solid and reliable equipment foundation for the stable operation of the fire safety system.