Multi-Power Configuration Diesel Fire Pump Unit | High-Efficiency Fire Water Supply

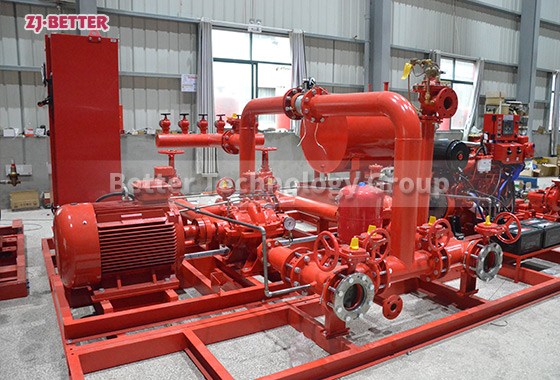

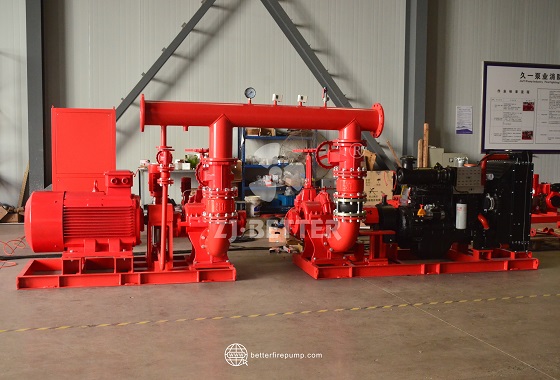

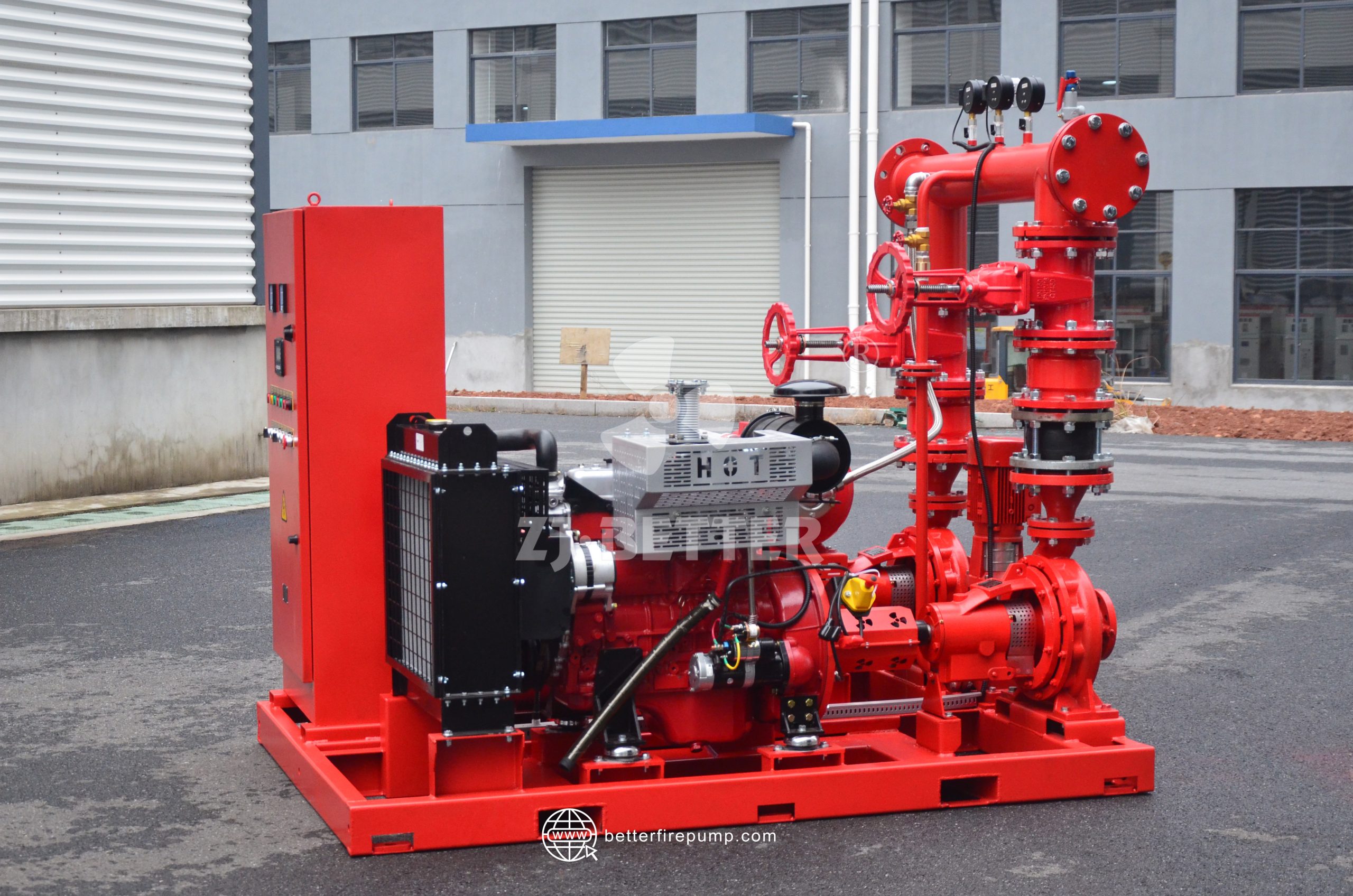

We offer high-performance diesel engine fire pump unit solutions, featuring strong power, automatic control, high reliability, and continuous and stable water supply capabilities. These solutions are suitable for fire protection systems in high-rise buildings, industrial plants, warehouses, and logistics facilities, enabling rapid pressurization and stable fire suppression in emergency situations.

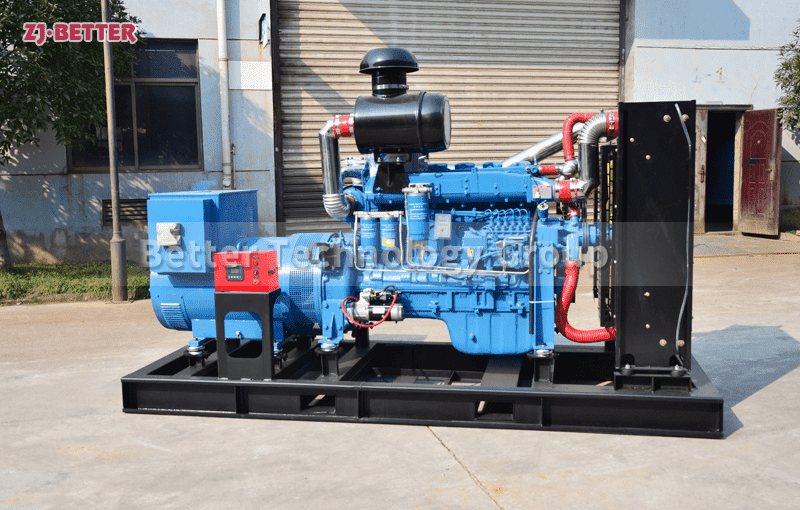

This diesel-powered fire pump unit, an indispensable core component of modern building fire protection systems, is a key fire protection facility prioritized by many engineering projects due to its powerful performance, independent operation capability, and high reliability in emergency situations. The diesel power system does not rely on mains power and can maintain stable output even in the event of power outages, line faults, or fires causing power interruptions, ensuring a continuous water supply to the fire protection system and serving as a vital emergency force for ensuring fire safety in critical locations. The entire unit consists of a diesel engine, fire pump, control cabinet, fuel system, cooling system, and base. Its compact structure, rational layout, and convenient maintenance make it suitable for various scenarios, including large commercial buildings, warehousing and logistics centers, industrial plants, municipal engineering projects, docks, and airports. Its greatest advantage lies in its strong power output capability. Diesel engines inherently possess characteristics such as high torque, high durability, and adaptability to harsh environments. Combined with a fire pump, it can instantly release high head and large flow, enabling the entire system to quickly establish pressure in the fire protection network, ensuring that sprinkler systems, fire hydrant systems, and various fire extinguishing devices reach operational status within a short time. For fire scenes requiring continuous water supply for extended periods, diesel-powered fire pumps can operate continuously without interruption, with low fuel consumption and minimal power attenuation, effectively meeting stringent rescue needs. Its second major highlight is its highly reliable control system. The intelligent control cabinet features multiple operating modes, including automatic, manual, remote, and linkage modes, and can automatically start the unit based on fire signals for rapid response. When the fire pressure drops to the set value, the system automatically enters operating mode; when the pipeline pressure recovers, the equipment automatically shuts down and remains in standby mode, truly achieving 24/7 intelligent protection. The control system employs multiple protection mechanisms, including high water temperature protection, low oil pressure protection, overspeed protection, three-leakage protection, and fire linkage protection, ensuring safe and stable operation of the unit under various conditions and preventing fire system paralysis due to malfunctions. The equipment design also emphasizes durability and adaptability. The engine is made of high-strength materials, enabling stable operation even in harsh environments such as high temperature, high humidity, and high dust levels; the fire pump section uses a corrosion-resistant structure and a thickened pump body, adapting to applications requiring prolonged static placement and sudden high-intensity operation. The entire system’s piping, pump shaft, mechanical seals, and other key components have been optimized to ensure long service life and high reliability. The base features an integral welded structure with vibration-damping design, resulting in low vibration and noise during high-speed operation, thus improving overall stability. Furthermore, the compact installation structure and small footprint allow for flexible placement in various machine room locations, making it particularly practical for projects with limited space. Ease of maintenance is another significant advantage. The unit’s layout fully considers future maintenance needs; filters, diesel tanks, cooling systems, and lubrication systems are all easily accessible from the outside, allowing maintenance personnel to quickly inspect, replace, and maintain components, significantly improving maintenance efficiency and reducing operating costs. The entire system also supports a remote monitoring interface, enabling integration with building fire protection systems and fire control rooms to achieve remote start-up, status monitoring, and fault alarm functions, improving overall management efficiency. In terms of performance, the diesel engine fire pump unit features high head, high flow rate, and strong suction, making it particularly outstanding in high-rise buildings, long-distance water supply, or high-pressure fire protection systems. Different models can be configured with varying power and pump types to meet the pressure and flow requirements of various operating conditions. Its dynamic response speed is fast, with an extremely short start-up time from receiving an instruction to reaching rated operating status, ensuring that the fire suppression system can be deployed immediately to extinguish fires and reduce the time it takes for the fire to spread. In terms of safety, the unit is equipped with an independent fuel system, allowing for long-term fuel storage, and features safety details such as fuel level alarms, leak-proof design, and fire-retardant coatings. The exhaust system is constructed from high-temperature resistant materials and equipped with heat insulation and noise reduction structures, effectively reducing heat radiation and noise impact. Some units also support dual-battery configurations to improve starting reliability and ensure successful ignition even in extreme environments. Environmental performance is also taken into consideration; the engine has been comprehensively optimized in terms of combustion efficiency, emission control, and energy-saving design, enabling the equipment to maintain strong power output while reducing emissions and meeting regulatory requirements. Application scenarios are very broad, including fire pump rooms, commercial complexes, manufacturing plants, energy stations, residential communities, urban infrastructure, and port projects. It is particularly suitable for projects with unstable power supply or requiring independent fire suppression systems, and is an important piece of equipment for improving overall fire safety levels. Its reliable performance under harsh operating conditions makes it a core support for high-standard fire protection systems. In summary, this diesel-powered fire pump unit plays a crucial role in various fire protection projects due to its powerful performance, intelligent control, high reliability, safe design, long-life structure, and adaptability to complex operating conditions. It not only meets daily fire standby needs but also ensures a continuous, stable, and high-flow water supply in emergencies, providing a solid guarantee for life and property safety. It is an irreplaceable and essential piece of equipment in modern building fire protection systems. Whether during the construction phase or after long-term operation, this equipment, with its robust performance and stable quality, has become the preferred configuration for high-standard fire protection systems, providing efficient, reliable, and safe fire extinguishing support for various fire scenarios, and is a core force in ensuring the fire safety of modern buildings.