The Optimal Solution for Modern Building and Industrial Fire Protection: Real-World Applications of Integrated Electric Fire Pump Stations

The integrated electric fire pump station offers a compact, intelligent, and energy-efficient solution for modern buildings and industrial fire protection, ensuring reliable and eco-friendly water supply with simplified maintenance.

With the rapid advancement of urbanization, building structures have become increasingly complex and industrial operations more intensive, placing greater demands on fire protection systems. Traditional fire pump configurations often suffer from long installation periods, complicated onsite debugging, and poor system compatibility, making them inadequate for the high-efficiency, intelligent, and reliable fire water supply systems required by modern buildings and industrial sites. Against this backdrop, the integrated electric fire pump station has emerged as a next-generation solution. With its compact structure, stable performance, intelligent control, and ease of maintenance, it is rapidly gaining prominence in the market.

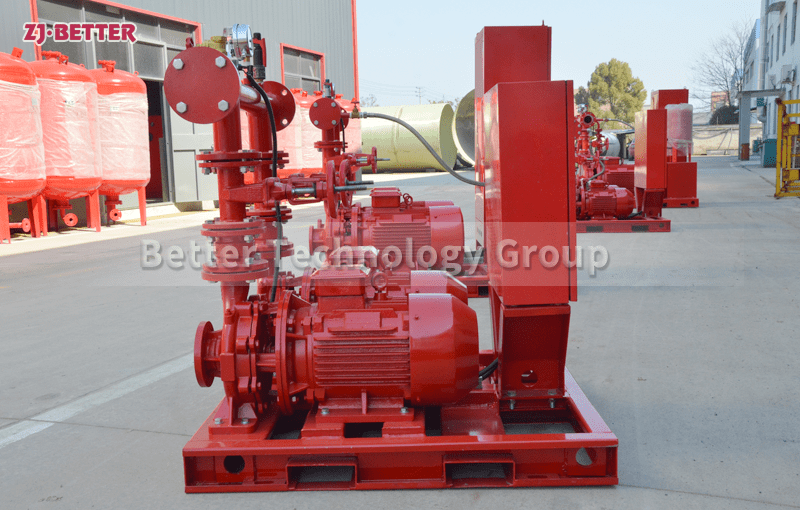

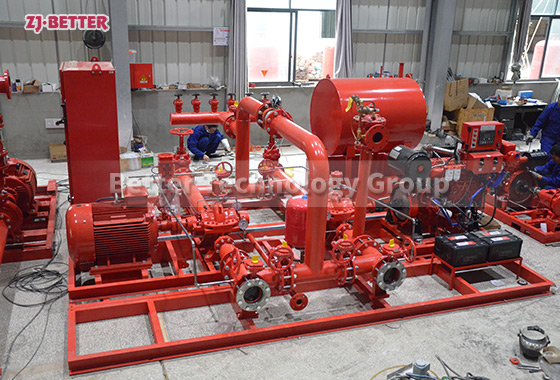

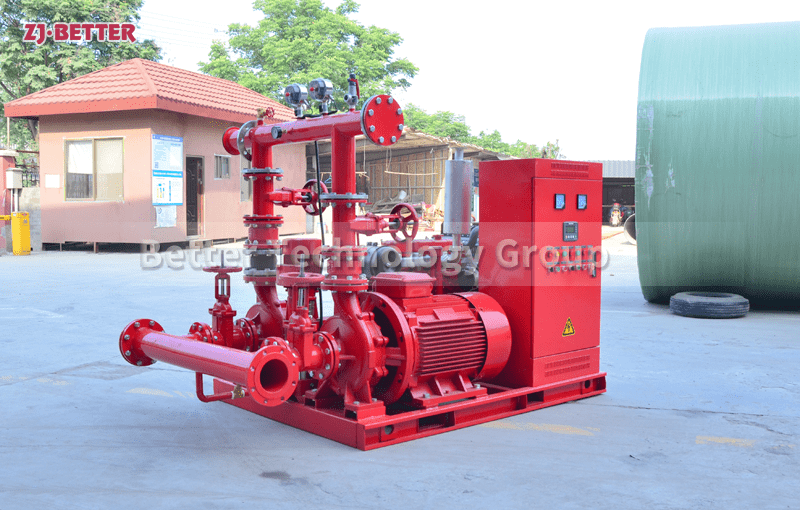

Typically composed of an electrically driven pump unit, starter control cabinet, piping system, automatic control system, pressure tank, and base, the integrated electric fire pump station is pre-assembled and tested at the factory before delivery. Onsite, only electrical and pipe connections are needed to put the system into operation quickly. This modular and highly integrated design significantly reduces engineering complexity and construction costs while greatly shortening installation cycles and enhancing the reliability and responsiveness of the fire protection system.

From a performance perspective, the pump station integrates high-efficiency centrifugal pumps, motors, and intelligent controllers to ensure constant water pressure while minimizing energy consumption. With the help of a frequency conversion system, the equipment automatically adjusts to match real-time water demand, improving system responsiveness and eliminating water hammer effects. This not only increases the overall lifespan of the equipment but also enhances its operational stability.

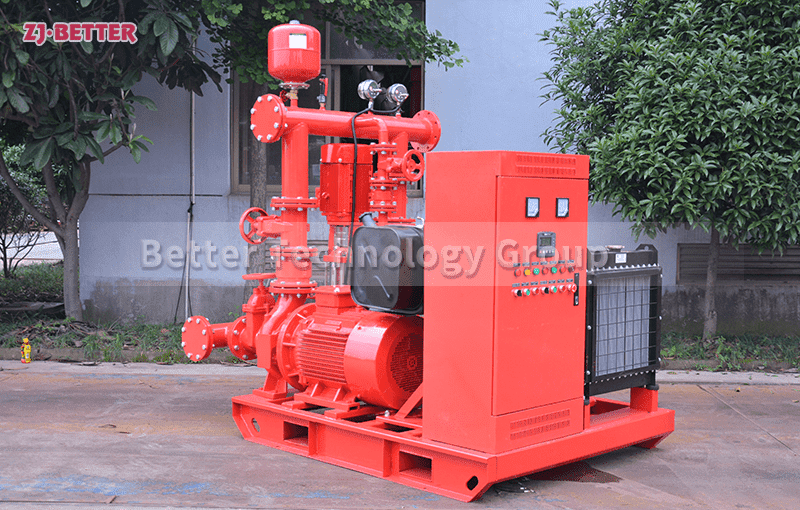

On the intelligence front, the system is equipped with advanced automatic control and remote monitoring capabilities. Through the integration of PLC programmable logic controllers and HMI human-machine interfaces, operators can view key data in real time, such as pressure, flow rate, current, voltage, and fault alarms. It supports RS485 and MODBUS communication protocols for seamless integration with building management systems. Some high-end models even offer cloud-based remote monitoring, allowing facility managers to oversee operations via smartphones or computers, facilitating unattended operation and preventive maintenance.

As for applicable scenarios, the integrated electric fire pump station is ideal for high-rise residential buildings, office complexes, commercial centers, underground parking facilities, large factories, and logistics centers—especially those with space limitations or urgent timelines. Its compact footprint and plug-and-play installation make it well-suited for projects with restricted machine rooms. Additionally, the pipeline system is fabricated with standard welding techniques and anti-corrosion lining, and it can be customized to meet specific design requirements.

In terms of environmental impact, the station features a sealed, leak-free design to prevent water contamination. Its electric drive produces zero noise and emissions, making it particularly valuable for green building projects and environmentally sensitive industries. The smart energy-saving mechanisms align with modern sustainability goals and contribute to long-term energy efficiency.

Maintenance is also simplified. Since the system is factory-tested and delivered as a complete unit, there is no need for extensive onsite calibration. Key components are arranged logically, and all controls are centralized on a single interface. The reduced number of pipe joints and electrical connections lowers the risk of leaks and malfunctions, enhancing the overall safety and stability of the system.

From a safety standpoint, the integrated fire pump station is equipped with multiple layers of protection and alarms, including overload protection, phase loss protection, over/under-voltage alerts, water shortage alarms, and overtime operation alarms. This ensures reliable operation during critical moments. Some models also include backup power interfaces or automatic switching devices, enabling seamless transition during power outages.

Market feedback indicates strong performance and customer satisfaction across numerous projects. In one provincial key construction project, installation was completed in under two hours, saving significant construction time. At a large manufacturing facility, the station provided continuous 24/7 monitoring and intelligent alerts, reducing fire risks and becoming the central pillar of the site’s fire protection system.

In conclusion, the integrated electric fire pump station is a high-performance, cost-effective, and intelligent fire protection solution that meets the stringent demands of modern buildings and industrial environments. It represents the future direction of fire pump technology and offers a reliable pathway toward safer, more efficient, and environmentally responsible fire safety systems.