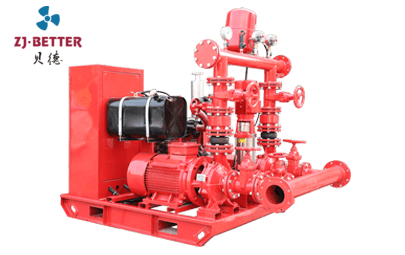

Why is EDJ fire pump set the safest, most practical and most comprehensive product?

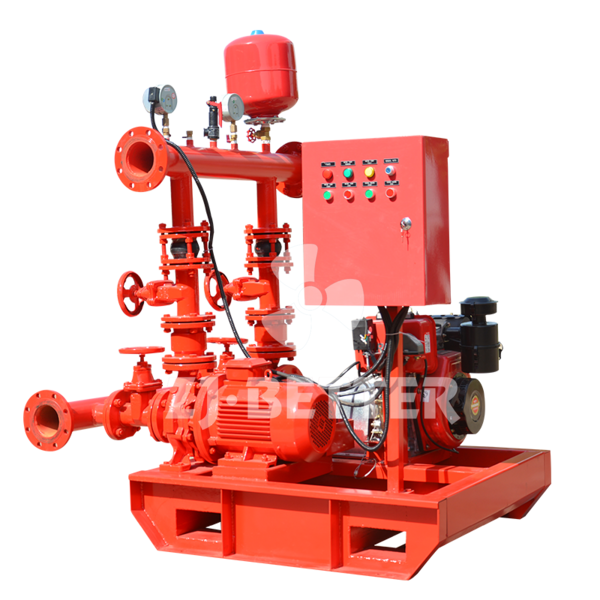

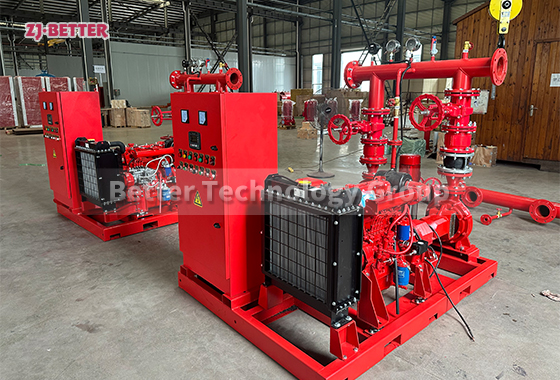

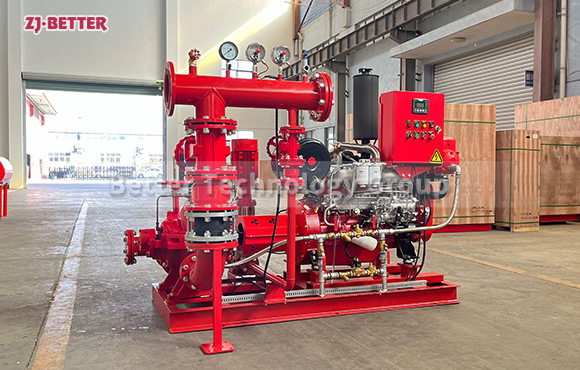

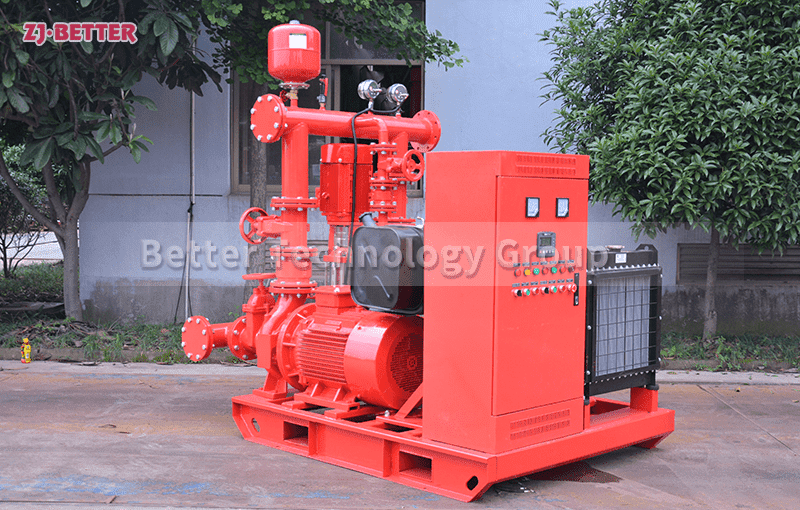

EDJ fire pump set is composed of electric pump, diesel pump and stabilized pressure pump. In daily use, as an auxiliary pump, the stabilized pressure pump keeps the existence of liquid (water) in the fire pipeline at all times, and the electric pump works as the main power pump in normal work. When the circuit system is burnt out due to a serious fire, the diesel pump will start instead of the electric pump within ten seconds, which will not be affected by the circuit and complete the fire fighting work. In recent years, EDJ fire pump group has gradually become the first choice of fire protection systems in various office buildings and residential buildings, and its safety

BETTER GROUP Technology Co, Ltd is a professional company that designs, develops, manufactures and sells general fluid equipment. The company cooperates with South Korea Hyundai pump, Japan Sita Co., Ltd. and other foreign famous pump and Valve Companies in strong technology, introduces internationally advanced design, development and enterprise management modes, and has long hired domestic and foreign pump and valve experts to provide technical guidance for the company. In March, 2014, the company signed a five-year pump product design and technical service contract with Zhejiang University of technology. As the scientific and technological achievements transformation base of the industrial pump Research Institute of Zhejiang University of technology, the company has laid a solid foundation for the company’s new product development and technological progress.

The main products of the company include submersible fire pumps, urban emergency drainage pumps, diesel fire pump sets, gas top pressure fire water supply equipment, oil-water separation equipment in catering industry, tank pump integrated fire pressurization and pressure stabilization water supply equipment, B-series submersible sewage pumps, AST series special sewage pumps for building civil engineering, WQ, QW series submersible sewage pumps, ISG, IRG, IHG, isgd series vertical pipeline pumps, ISW, iswd series horizontal centrifugal pumps, DL type vertical multistage pumps GDL portable pipeline multi-stage pump, LG, LG-B portable high-rise building water supply multi-stage pump, etc. The main products of the company are in line with the high-tech fields supported by the state.