How Does This Fire Pump Optimize Hydraulic Design to Improve Efficiency and Reduce Energy Consumption?

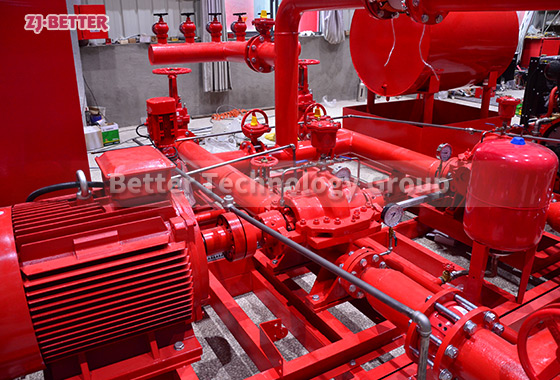

This fire pump features an advanced hydraulic design that optimizes flow channel structure, effectively reducing hydraulic losses and improving operational efficiency. The high-efficiency impeller and precisely optimized fluid dynamics ensure a smoother water flow, minimizing turbulence and energy loss for better energy conversion.

Additionally, the pump is equipped with a high-performance sealing system that minimizes leakage, ensuring long-term stable operation while reducing maintenance costs. The pump body is made of corrosion-resistant materials, extending its lifespan and maintaining high performance even in harsh environments.

In real-world applications, this fire pump is widely used in industrial, commercial, and high-rise building fire protection systems, providing reliable fire suppression when it matters most.

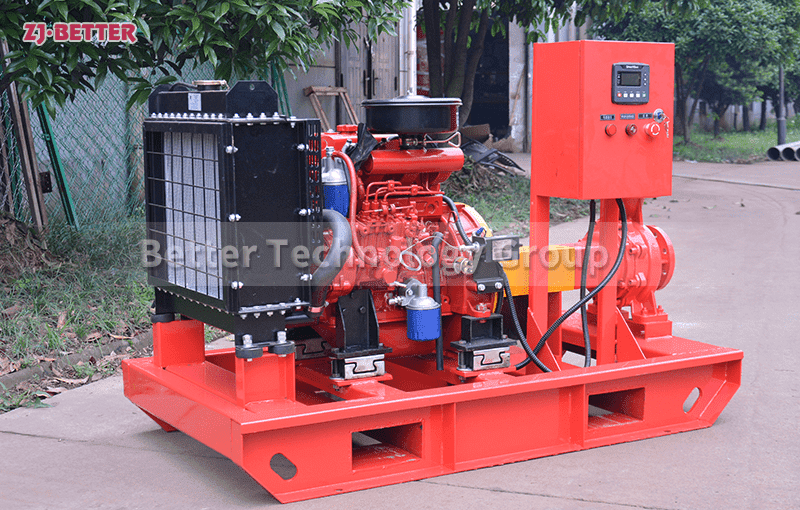

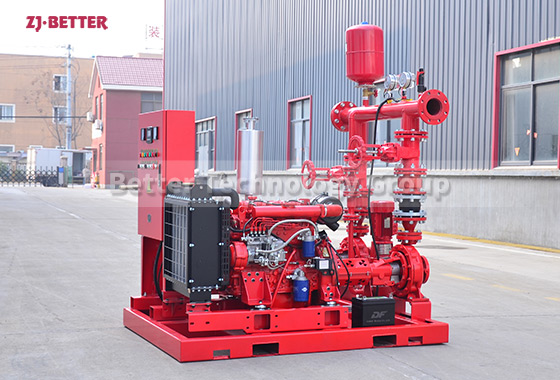

Our company specializes in the research, development, production, and sales of fire pumps, dedicated to providing efficient, reliable, and safe fire protection systems for global customers. Our product line includes electric fire pumps, diesel engine fire pumps, and pressure-stabilizing water supply systems, widely used in industrial, commercial, high-rise buildings, and municipal engineering projects. All products strictly adhere to ISO, NFPA, and other international standards, ensuring superior quality and safety. The optimized hydraulic design significantly enhances operational efficiency, reduces energy consumption, and minimizes maintenance costs. Additionally, the smart control system integrates automatic start/stop, remote monitoring, and fault alarm functions for enhanced user convenience. Constructed with high-strength materials and anti-corrosion coatings, our equipment offers exceptional durability and adaptability, maintaining stable performance even in harsh environments. With outstanding product performance and comprehensive after-sales service, our fire pump systems have been exported to numerous countries and regions, providing reliable fire protection for diverse buildings and projects. Moving forward, we will continue to drive technological innovation and product upgrades, contributing to the advancement of the fire safety industry and delivering superior solutions to our customers.