In modern firefighting systems, the accessibility and efficiency of water sources are critical to the overall success of any fire suppression operation. Especially in areas without municipal water networks—such as industrial zones, mining sites, oil fields, remote villages, and forest protection zones—the ability to extract and deliver underground water efficiently becomes a key technical challenge. To address this, we introduce the Diesel Engine-Driven Vertical Turbine Fire Pump, a high-performance solution specifically designed for deep-well water extraction under demanding conditions.

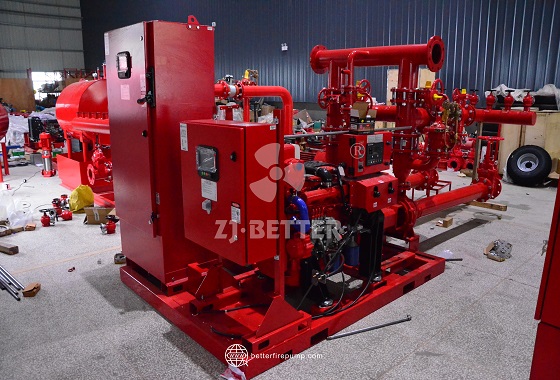

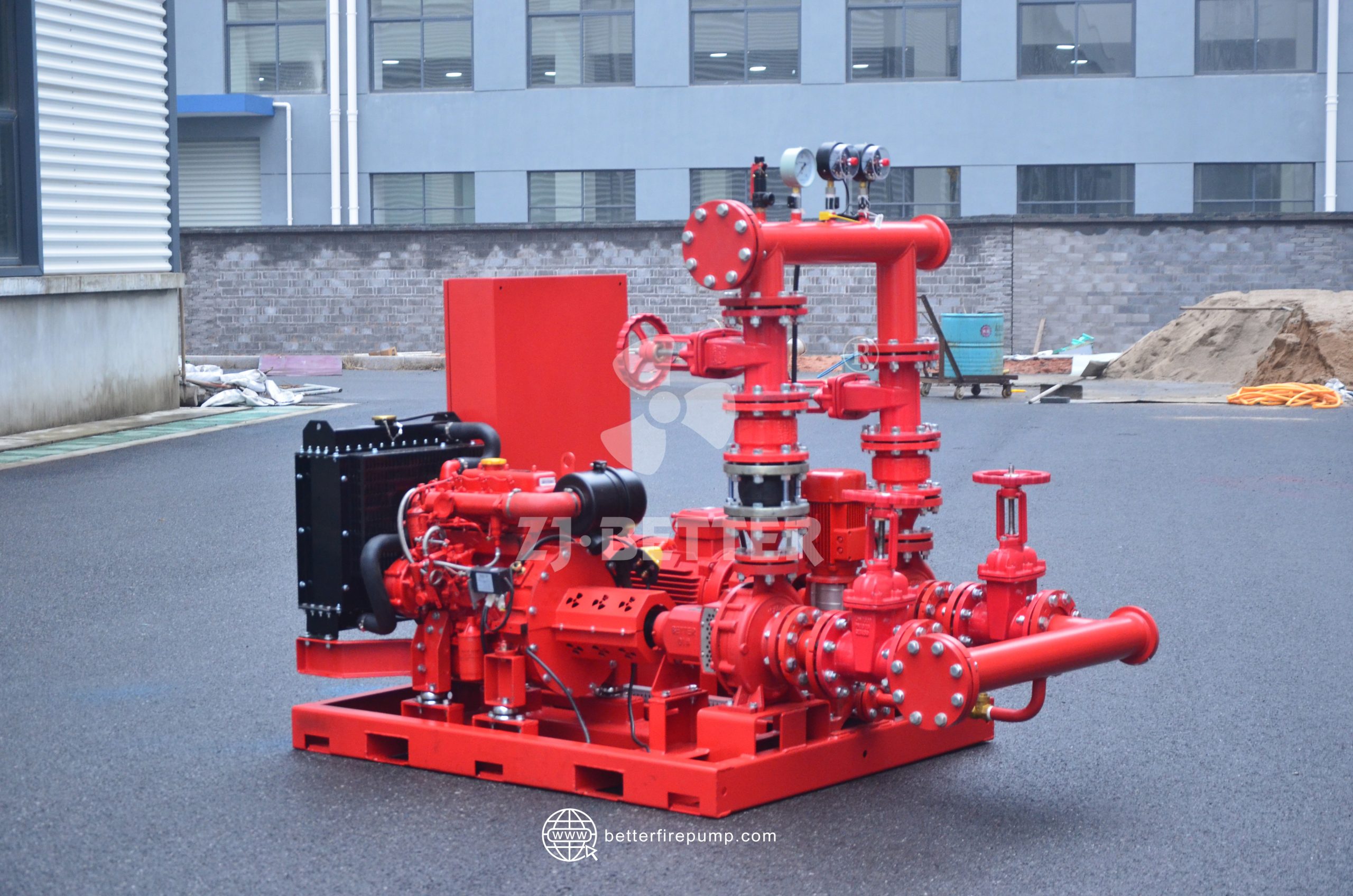

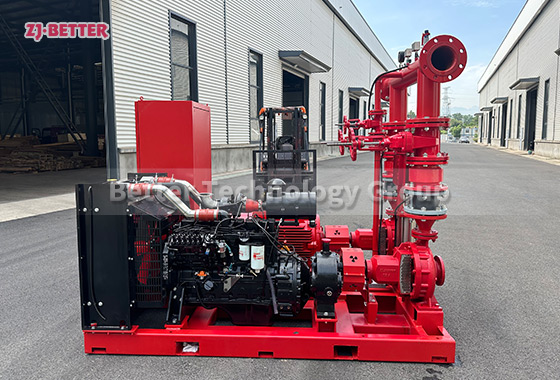

This unit features a diesel-powered drive system, eliminating reliance on grid electricity. It can operate reliably in areas with no power or unstable power supplies, making it ideal for field emergency deployment or locations with underdeveloped infrastructure. Compared with electric pumps, diesel engines offer superior adaptability and independence, providing crucial support in remote or harsh environments.

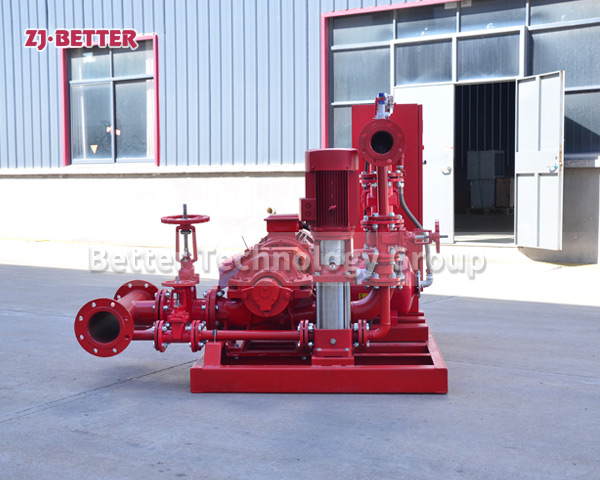

At the heart of the system is the vertical long shaft multistage pump design, which can reach depths of tens or even over a hundred meters to extract water directly from underground sources. Its robust shaft and high coaxial precision, supported by precision guide bearings, ensure minimal vibration and wear, thereby greatly extending the system’s service life. The modular structure simplifies on-site installation and maintenance, making it well-suited for confined wellheads and compact system layouts.

In terms of hydraulic performance, the vertical turbine pump delivers high head and large flow rate, ensuring fast water extraction and continuous supply over long periods. With pump casing and impellers made from corrosion-resistant cast iron or stainless steel, it can withstand various water qualities and fluctuating temperatures, ideal for long-term submersible use. Whether for emergency firefighting or system backup water supply, this pump ensures uninterrupted performance.

The entire system also comes with an intelligent control module, integrating ECU management and emergency shutdown protection. It provides real-time monitoring and alarms for parameters such as temperature, pressure, and RPM, ensuring safe operation under extreme conditions. Users may optionally equip the system with remote monitoring capabilities, allowing for remote start/stop and full operation data logging, which greatly enhances management efficiency.

In summary, the Diesel Vertical Turbine Fire Pump is a comprehensive solution featuring deep-well extraction capability, autonomous emergency operation, robust hydraulic performance, easy maintenance, and intelligent control. It is widely applicable in power-deficient or geographically challenging regions for firefighting water supply. More than just a pump, it provides a reliable, professional answer to underground water sourcing for firefighting, both in China and for global users.