Fire Safety Enhancement with Efficient Pressure-Maintenance and Main Pump Linkage Systems

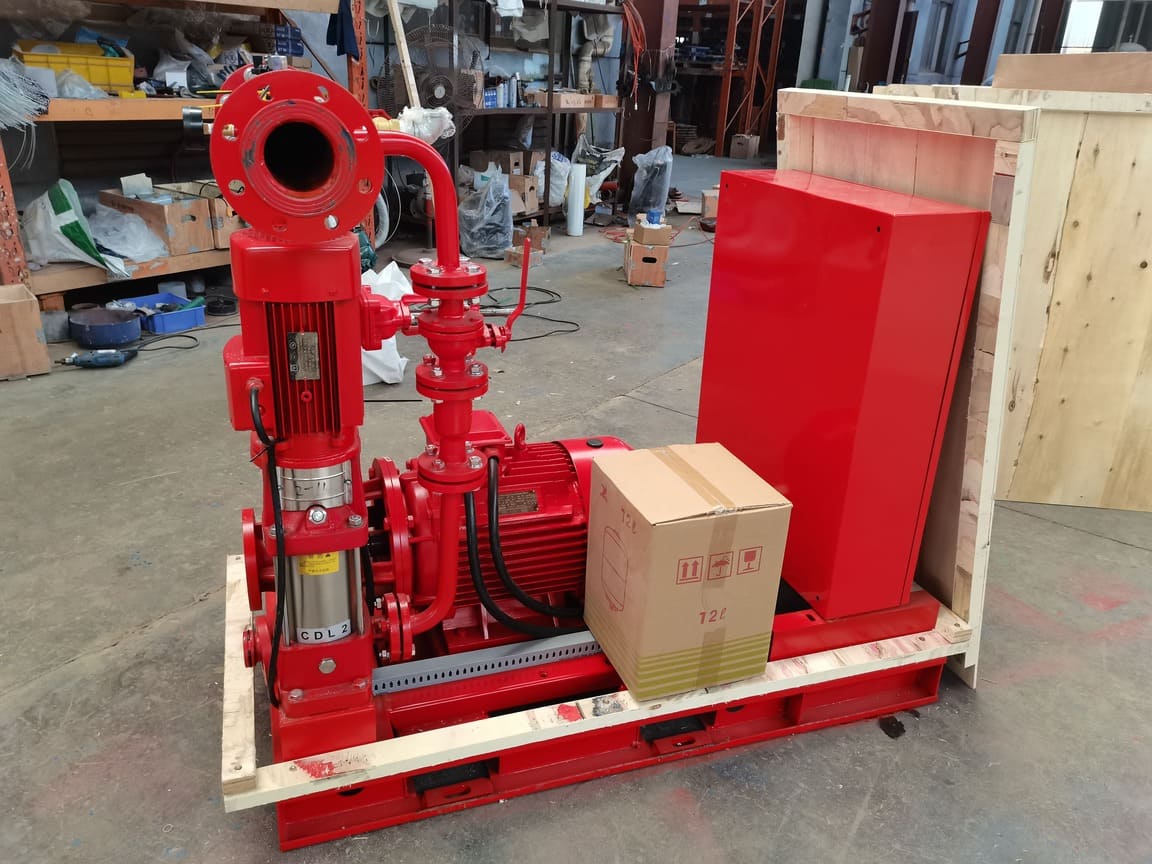

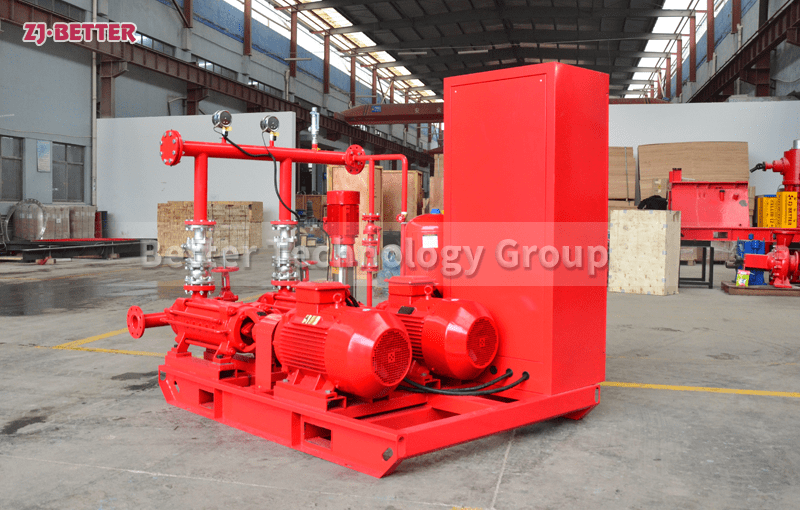

The high-efficiency pressure stabilization and main pump linkage system achieves rapid response, continuous stability, and high-pressure fire water supply performance through intelligent pressure control, automatic start-stop logic, and dual power redundancy design. It is suitable for high-rise buildings, industrial facilities, and large-scale fire protection systems, effectively improving overall fire safety and reliability, and is the best choice for ensuring fire water supply in critical locations.

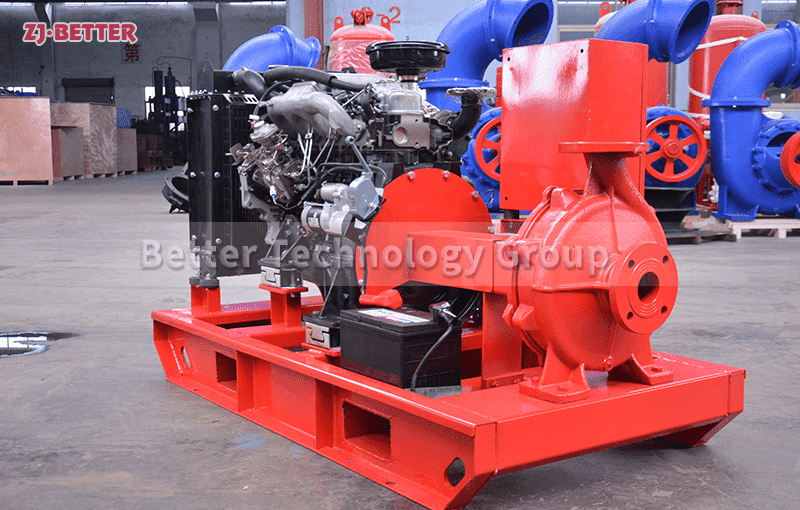

To meet the high standards of modern buildings and industrial facilities for the continuous and stable operation of fire-fighting water supply systems, high-efficiency pressure stabilization and main pump linkage systems have gradually become an indispensable core component of fire protection engineering. This system not only solves the shortcomings of traditional equipment in terms of frequent start-stop cycles, pressure fluctuations, and response delays, but also provides safer, faster, and more efficient water supply guarantees during the initial, development, and entire fire-fighting process through highly automated control logic. The high-efficiency pressure stabilization system uses small-flow, high-lift pumps to maintain a constant pressure in the pipeline network over a long period, keeping the entire fire-fighting pipeline in a state of readiness. If leakage, slight flow, or pressure drop occurs at the end, the pressure stabilizing pump will immediately and automatically… The system starts and replenishes pressure to maintain the pipeline pressure within the set range, preventing the sprinkler system from failing to open in time due to insufficient pressure. It also prevents the main pump from starting accidentally due to slight pressure drops, thereby extending the lifespan of the main pump and diesel pump and significantly reducing system energy consumption. When the system pressure drops rapidly or a large flow water intake signal appears, the pressure stabilizing pump will transmit this information to the control system. The control system will determine that this is a fire start-up condition and instruct the main pump or diesel pump to start operation, achieving a seamless switch from small pump to large pump. This design allows the fire protection system to form an effective high-pressure water supply as quickly as possible in the early stages of a fire, reducing the spread of danger caused by delayed response and significantly improving overall fire protection performance. A high-efficiency pressure stabilization and main pump linkage system typically consists of an electric main pump, a diesel backup pump, a pressure stabilizing pump, a pressure tank, a check valve, a control cabinet, and a complete piping structure. The electric main pump, as the primary water supply equipment, can instantly provide a stable water source with a large flow rate and high head. Its compact structure and high efficiency make it suitable for daily fire protection needs. The diesel backup pump provides emergency power in case of mains power failure or when the electric pump cannot be used. It features self-fuel-driven operation, strong torque, and high output power, maintaining a stable water supply even in harsh environments, ensuring dual redundancy for the system. The pressure stabilizing pump maintains the static pressure in the pipeline, eliminating the need for frequent start-stop operations of the main pump and ensuring that terminal devices always have pressure response, preventing system failure due to insufficient pressure. Furthermore, the pressure tank reduces the number of start-stop operations of the pressure stabilizing pump and buffers water flow within the pressure stability range. The check valve and various safety valves ensure proper water flow direction, prevent backflow, and provide more comprehensive pressure protection. One of the biggest advantages of the high-efficiency pressure stabilization and main pump linkage system is the intelligent integration of automated control logic. Through various pressure sensors, electrical contact pressure gauges, flow signal acquisition, liquid level monitoring, and fault detection modules, the control cabinet can manage the entire system in real time. When the pipeline pressure drops slightly, only the pressure stabilizing pump is activated; when the pressure drops significantly to the activation set value, the main pump is immediately engaged. If the main pump fails to start or the main power supply is abnormal, the system automatically switches to diesel pump operation, thus maintaining uninterrupted fire water supply. This fully automatic linkage logic requires no manual intervention, giving the fire protection system a high degree of responsiveness. Even at night, in unattended locations, or at remote sites, it can ensure immediate operation in the event of a fire. Furthermore, the control cabinet supports manual, automatic, and emergency modes, and can be intervened via buttons, remote terminals, or linkage signals. It also stores various types of operating data and fault records, facilitating later maintenance and system analysis. The system also boasts significant performance advantages. Its efficient pressure stabilization control minimizes pipeline pressure fluctuations, ensuring optimal startup conditions for sprinkler, fire hydrant, deluge, and foam systems. The main pump’s high-flow-rate design guarantees sufficient water pressure during the fire spread phase, enabling stable and powerful fire suppression. In locations sensitive to fire water pressure, such as large factories, chemical industrial zones, warehousing and logistics centers, high-rise buildings, subway stations, hospitals, and power plants, this system provides long-term, stable, low-failure-rate, and rapid-response fire protection, elevating the reliability of the entire fire protection system to a new level. Furthermore, this type of system excels in energy efficiency. The pressure-stabilizing pump has a much lower power consumption than the main pump, maintaining static pressure instead of frequent main pump start-stop cycles, significantly reducing overall system energy consumption. The diesel pump employs an optimized combustion and automatic preheating structure, allowing for rapid startup even in low-temperature environments, ensuring emergency response is unaffected by weather. It features high fuel efficiency, low maintenance requirements, and controllable operating costs. The main pump utilizes a high-efficiency hydraulic model, achieving a significantly higher overall energy efficiency than traditional equipment, resulting in substantial energy savings for long-term industrial fire protection systems. In terms of structural design, the system adopts an integrated unit form, integrating the main pump, standby pump, pressure stabilizing pump, pipelines, valves, base and control unit on the same platform, which greatly reduces the difficulty of on-site installation, shortens the construction period, simplifies on-site connection, and makes commissioning faster and more efficient. The integrated structure reduces pressure loss, vibration and noise caused by non-standard pipeline installation, and the equipment operates more smoothly. In addition, all components of the system are designed according to fire protection standards, and have the characteristics of high durability, corrosion resistance, and stable seismic structure, which enables the equipment to withstand high-intensity working conditions for a long time without easily failing. In terms of maintenance, the high-efficiency pressure stabilizing and main pump linkage system adopts a modular layout, allowing the pressure stabilizing pump, main pump, motor, diesel engine, and control cabinet to be independently inspected and repaired. This facilitates quick fault location and component replacement. Its lubrication system, cooling system, coupling structure, and valve settings all adopt a design concept that facilitates disassembly and assembly, reducing maintenance frequency and shortening maintenance time. The system has an automatic inspection function, which can start the equipment at regular intervals for short-term operation tests to ensure normal motor lubrication, optimal diesel engine condition, and stable pump body sealing. This avoids problems such as jamming, oxidation, or pressure loss caused by long-term idleness. The high-efficiency pressure stabilizing pump also performs periodic self-checks to ensure the continuous and effective maintenance of pipeline pressure. Overall, the high-efficiency pressure stabilization and main pump linkage system not only enhances the overall safety of the fire water supply system, but also significantly improves the start-up speed, water supply capacity, operational stability, and long-term economic efficiency. Whether in large public buildings, industrial parks, underground spaces, high-rise buildings, pressure-sensitive systems, or unattended sites, this system can provide a high level of fire water supply guarantee. Through intelligent linkage, redundant power, and high-efficiency hydraulic performance, it achieves truly reliable fire protection. Its rapid response capability and multi-level linkage control allow the fire protection system to demonstrate stable and powerful performance at critical moments, providing a high level of technical support and protection for fire safety.