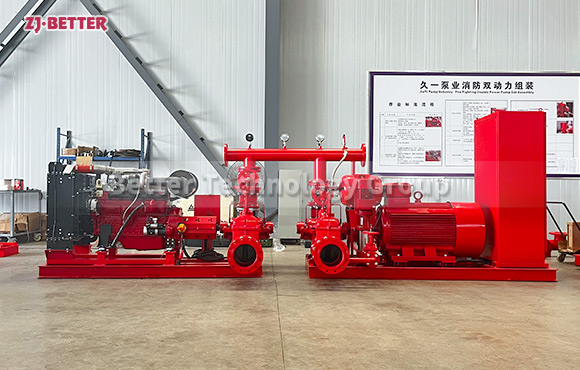

Diesel Fire Pump Unit for Critical Infrastructure with Durable and Reliable Performance

Diesel Fire Pump Unit for Critical Infrastructure delivers stable high-pressure performance, independent diesel power, rapid emergency response, and long-term continuous operation. Designed for industrial facilities, power plants, commercial complexes, and municipal systems, this heavy-duty fire water pump system ensures reliable fire protection, strong flow capacity, automatic control integration, durable construction, and efficient maintenance for mission-critical safety applications.

Critical infrastructure diesel fire pump units are stable, durable, safe, and reliable. Designed for applications with extremely high reliability requirements for fire protection systems, these high-power, independent power supply units utilize a high-performance diesel engine as their core drive source, paired with a high-efficiency centrifugal fire pump. Through precise power matching and an integrated base structure design, they achieve powerful output and long-term stable operation. Widely used in critical infrastructure projects such as data centers, power facilities, petrochemical bases, transportation hubs, airports, ports, hospitals, large industrial parks, and key municipal projects, these units can operate independently even in the event of a mains power outage or emergency, continuously providing a stable and sufficient fire water supply. The diesel fire pump unit employs a high-torque diesel engine, featuring rapid response and high load capacity. It quickly reaches rated speed during startup, ensuring the fire protection system establishes the required pressure in the shortest possible time, meeting the stringent flow and head requirements of various fire extinguishing methods such as sprinkler systems, fire hydrant systems, and foam extinguishing systems. The engine’s fuel system is optimized for high combustion efficiency and stable output power, maintaining steady power output even during long-term continuous operation, ensuring uninterrupted fire fighting. The entire unit is equipped with a high-efficiency cooling system, including a large-capacity radiator and a circulating cooling structure, effectively controlling engine temperature and preventing overheating that could lead to performance degradation. Simultaneously, air and fuel filtration systems ensure stable operation in dusty or complex industrial environments, enhancing the equipment’s adaptability. The pump body is constructed from high-strength cast iron or ductile iron, ensuring a robust and pressure-resistant structure. The internal impeller and guide structure undergo precision machining and dynamic balancing, optimizing the hydraulic flow channel design to reduce hydraulic losses and improve overall efficiency. This allows the equipment to maintain excellent performance curves even under high head and high flow conditions, making it particularly suitable for long-distance water transmission and vertical water supply needs in high-rise buildings. The integrated steel base structure enhances overall rigidity and stability, while the vibration-damping design effectively reduces operational vibration, ensuring the mechanical safety of the equipment during long-term operation. It also facilitates overall hoisting and on-site installation, improving engineering construction efficiency. The control system features an intelligent design, enabling automatic start-up, automatic shutdown, fault alarms, and operational parameter monitoring. When the pipeline pressure falls below a set value, the system automatically starts the diesel engine to drive the pump unit without manual intervention, significantly improving emergency response speed and ensuring critical facilities receive stable water supply support immediately in the event of a fire. The control panel displays key data such as water temperature, oil pressure, speed, battery voltage, and running time, allowing maintenance personnel to monitor equipment status in real time, perform proactive maintenance and repairs, and extend service life. To meet the high safety requirements of critical infrastructure, this unit can be configured with an electric fire pump, enabling primary/standby switching. The electric pump operates when power is normal, and the diesel pump automatically takes over in case of power failure or abnormality, forming a multi-layered protection mechanism that significantly improves the overall reliability of the fire protection system. The fuel tank capacity can be customized according to project scale to meet the needs of long-term continuous operation, ensuring continuous water supply even in complex disasters or power restoration delays. The coupling uses high-precision coaxial alignment technology to reduce energy loss and mechanical wear during power transmission, extending the service life of the pump shaft and bearings. The mechanical seal system is made of wear-resistant and high-temperature-resistant materials, maintaining good sealing performance even under high-pressure operating environments to prevent leakage from affecting system safety. The entire unit’s exterior is treated with an industrial-grade anti-corrosion coating, possessing excellent oxidation resistance and weather resistance, and can adapt to high-temperature, high-humidity, or corrosive environments. This diesel fire pump unit was designed with international fire protection engineering standards and the needs of projects in different regions in mind. It can be customized according to flow rate, head, and power parameters to meet the diverse design requirements of large commercial buildings, municipal engineering projects, and industrial projects. Before leaving the factory, the equipment undergoes rigorous performance testing, pressure testing, and load operation testing to ensure proper matching between the diesel engine and pump body, and stable and reliable operation. Its high head output capacity effectively overcomes the resistance of long-distance pipelines and the effects of height differences, ensuring that fire protection facilities at the most unfavorable points reach the design pressure. For critical locations such as data centers, power substations, and chemical plants, a continuous and stable fire water supply is a crucial prerequisite for ensuring the safety of personnel and equipment. This unit, with its independent power system and high-efficiency hydraulic performance, provides 24/7 standby support for critical facilities. In terms of maintenance design, the equipment has a reasonable structural layout, and key components are easy to disassemble and replace, reducing downtime and improving equipment availability. By optimizing the matching of engine speed and pump performance curves, the unit maintains high efficiency under different loads, reducing fuel consumption and controlling operating costs. The overall design balances high performance, durability, and safety, maintaining stable performance even under long-term operation and frequent start-stop conditions, thus building a reliable fire protection barrier for critical infrastructure. Whether in new large-scale engineering projects or upgrades of existing systems, this critical infrastructure diesel fire pump unit is an ideal choice due to its strong power output, stable operation, and independent water supply. It continuously provides a powerful and reliable water source in the event of a sudden fire or power outage, safeguarding the safe operation of important facilities and building a safer and more robust fire water supply system.