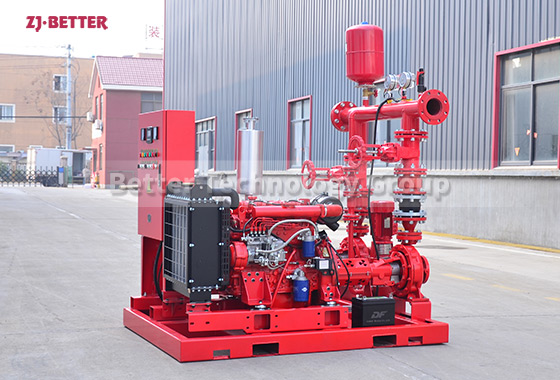

Rapid and Effective: EJ Fire System with end suction pump

Flow: 30-9000 GPM

Head: 3-20Bar

Speed: 740-2900r/min

Material: HT200, SS304, Bronze

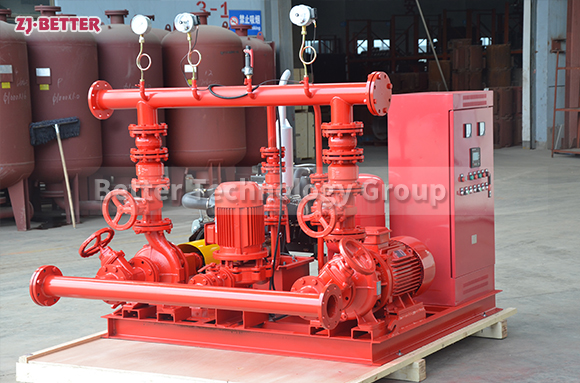

The EJ Dual Power Fire Pump System is an innovative and reliable fire protection solution. Combining an electric pump for robust water pressure and flow with a top-quality jockey pump for stable pressure maintenance, this system ensures efficient and timely water supply during fires. With advanced automation, remote monitoring, and energy-saving features, the EJ Dual Power Fire Pump System is a trusted choice for commercial, industrial, and residential applications.

Types of pumps used for fire service include: End Suction Pump, Split Case Pump, Vertical Inline Pump and Vertical Turbine Pump.

1. Electric motor driven pump, can use single stage pump, horizontal split case pump, end suction pump,multistage pump.

2.Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump.

3. Control panel: Auto Control of electric pump, diesel engine pump and Jockey Pump with overload, over current protection.

In summary, the EJ Fire Pump System stands out for its high-performance capabilities, intelligent control features, remote monitoring and control capabilities, energy efficiency, and overall reliability and durability. It is an ideal choice for fire protection needs.