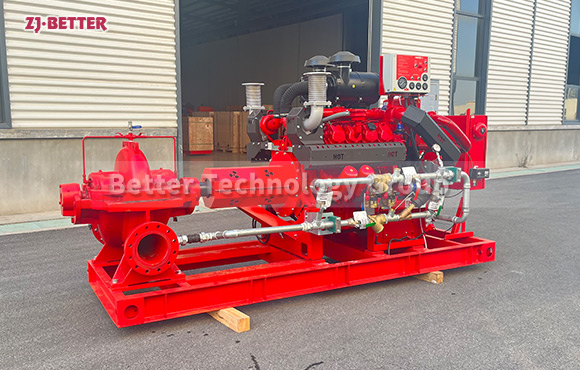

EJ Fire Pump set

Operation of Electric Fire Pump Before start: 1. Turning the clutch by hand, there should be no jammed phenomenon at the turner position. 2. Opening the inlet valve and the vent valve, letting the water fill into the pump’s chamber, then closing the vent valve. 3. Clicking the switch of motor, and confirming whether the turning is right ornot. Running: 1. Fully opening the inlet valves, and closing the valves of the outlet pipe. 2. Connecting the power, Opening the valves of the outlet pipe and adjusting the needed working point when the turning velocity is normal. 3. Watching whether there exist abnormalities or not, if yes, should the pump be stopped and inspected before re-running. Stop: 1. After turning off the outlet valves one by one, shutting off the power. 2. Shutting off the inlet valves. 3. If the ambient temperature is below 0℃, some warm-keeping measures should be adopted.

Operation of Electric Fire Pump Before start: 1. Turning the clutch by hand, there should be no jammed phenomenon at the turner position. 2. Opening the inlet valve and the vent valve, letting the water fill into the pump’s chamber, then closing the vent valve. 3. Clicking the switch of motor, and confirming whether the turning is right ornot. Running: 1. Fully opening the inlet valves, and closing the valves of the outlet pipe. 2. Connecting the power, Opening the valves of the outlet pipe and adjusting the needed working point when the turning velocity is normal. 3. Watching whether there exist abnormalities or not, if yes, should the pump be stopped and inspected before re-running. Stop: 1. After turning off the outlet valves one by one, shutting off the power. 2. Shutting off the inlet valves. 3. If the ambient temperature is below 0℃, some warm-keeping measures should be adopted.