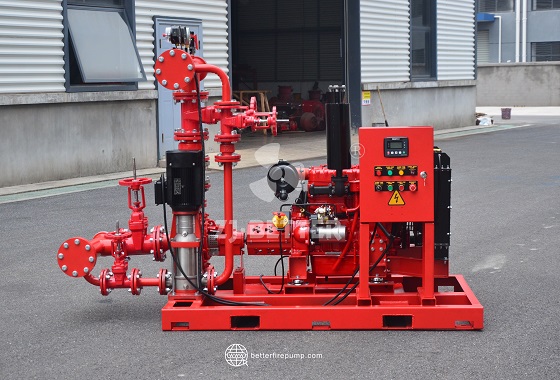

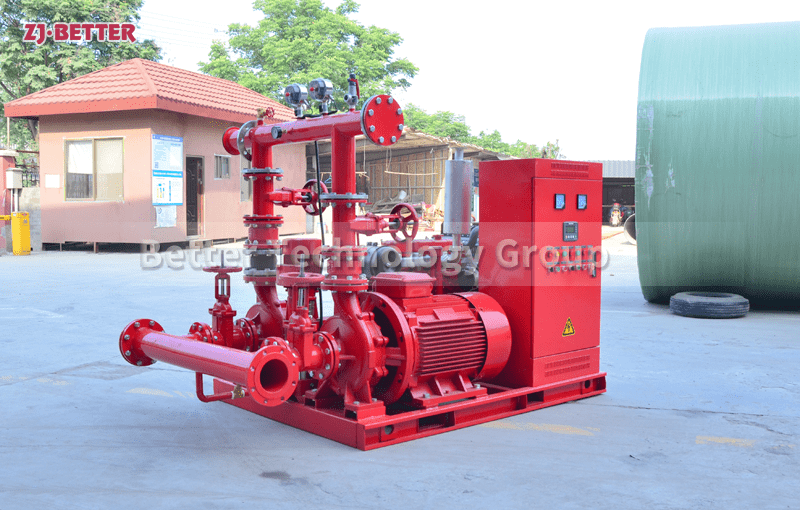

Water Cooled Diesel Fire Pump Equipment for Long Time Heavy Load Operation

Water-cooled diesel fire pumps employ a high-efficiency heat dissipation system, supporting stable operation under high loads for extended periods. They feature high flow output and reliable start-up performance, making them suitable for large-scale industrial and key fire protection projects, ensuring continuous and safe fire water supply.

Water-cooled diesel fire pumps are core fire-fighting water supply equipment specifically designed for high-load, long-term operation. Their key feature lies in the deep matching of a high-efficiency water-cooling system with a diesel power system, significantly improving the stability and reliability of the equipment under continuous operating conditions. They are particularly suitable for large industrial facilities, warehousing and logistics centers, energy projects, ports, and other key projects with extremely high requirements for continuous fire-fighting water supply. These devices use a diesel engine as their power source and are capable of operating completely independently of mains power. They can maintain normal operation even during power outages or when the power supply is unstable, providing reliable protection for the fire-fighting system. The water-cooled structure is one of the key performance advantages of this equipment. Through the configuration of a large-capacity radiator and a rationally arranged cooling water circulation system, the operating temperature of the engine and key components is effectively controlled. Even under high ambient temperatures or prolonged full-load operation, a stable thermal balance is maintained, preventing power attenuation or equipment failure due to overheating. This ensures that the fire pump continuously outputs a stable water supply throughout the entire fire-fighting process. Diesel engines possess strong torque output and excellent load adaptability, rapidly reaching operating speed after startup and maintaining a stable state during operation. This provides continuous and reliable power support for the fire pump, ensuring stable performance even under high flow and high head conditions. The pump body is typically constructed from high-strength materials, exhibiting excellent pressure resistance and impact resistance. The internal hydraulic flow channels are optimized to effectively reduce hydraulic losses and improve overall efficiency, enabling the equipment to achieve stable and efficient water supply output while meeting fire safety regulations. Water-cooled diesel fire pumps prioritize overall rigidity and operational balance in their structural design. The engine, pump unit, cooling system, and control components are uniformly mounted on a reinforced base, resulting in a rational layout that effectively reduces operational vibration and noise, minimizing environmental impact and extending the overall service life. These devices are usually equipped with comprehensive control and monitoring systems that can monitor engine speed, oil pressure, water temperature, and pump unit operating status in real time. In case of abnormal conditions, alarm signals are promptly issued, facilitating rapid problem-solving by maintenance personnel and enhancing the safety and controllability of the fire protection system. To address the stringent requirements for rapid start-up in fire suppression systems during a fire, water-cooled diesel fire pumps have undergone targeted optimization in terms of start-up performance. Through rational control logic and power matching, the equipment can quickly commence operation upon receiving a start-up command, establishing stable pipeline pressure within a short time to provide sufficient water for initial fire suppression. The ability to operate under high loads for extended periods is one of the core competitive advantages of this type of equipment. By strengthening the shaft system design, selecting high-temperature and wear-resistant bearing components, and optimizing lubrication and cooling methods, the pump unit maintains excellent mechanical performance under continuous operation, significantly reducing the failure rate and meeting the continuous operation requirements of fire suppression equipment in large-scale engineering projects. Water-cooled diesel fire pumps also excel in environmental adaptability. Their structural design and surface protection treatment enable them to adapt to complex operating conditions such as high temperature, high humidity, dust, or outdoor exposure, ensuring stable operation in various installation environments and minimizing susceptibility to external conditions. The equipment also boasts significant advantages in installation and maintenance. Its clear overall structure and rational layout of key components facilitate daily inspections and periodic maintenance. Maintenance work primarily focuses on checking the cooling system, fuel system, and lubrication condition. The process is standardized and controllable, helping to ensure the equipment maintains optimal performance during long-term standby. To meet the specific needs of different engineering projects, water-cooled diesel fire pumps can be flexibly configured according to design conditions, including different flow rates, heads, engine power, and interface types, to adapt to complex and ever-changing fire protection piping systems. Before leaving the factory, the equipment typically undergoes rigorous performance testing and operational verification to ensure that all parameters meet design requirements under high-load conditions, providing reliable assurance for project delivery and subsequent operation. Overall, water-cooled diesel fire pumps, with their superior heat dissipation capacity, stable power output, excellent continuous operation performance, and good environmental adaptability, have become key equipment in demanding fire protection engineering, providing long-lasting, safe, and reliable fire water supply support for large projects and key locations, demonstrating extremely high practical value and engineering reliability in actual applications.

-2.jpg)