From Design to Installation: How to Ensure the Best Performance of Fire Pumps?

As the core component of a fire protection system, the performance of fire pumps directly affects fire suppression efficiency. To ensure optimal performance, we maintain strict control over every stage, from design and manufacturing to installation and maintenance.

In the design phase, we utilize advanced fluid dynamics technology to optimize the pump structure, minimizing energy loss and maximizing water flow efficiency. The carefully designed impeller and flow channels enable the pump to maintain stable operation under high pressure while reducing noise and vibration, thereby extending its service life.

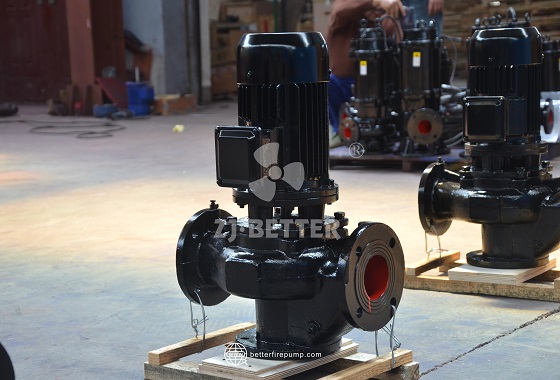

During the manufacturing process, we select high-strength, corrosion-resistant materials such as stainless steel and ductile iron to ensure durability in harsh environments. Precision machining and rigorous quality inspections guarantee that every fire pump meets industry standards before leaving the factory.

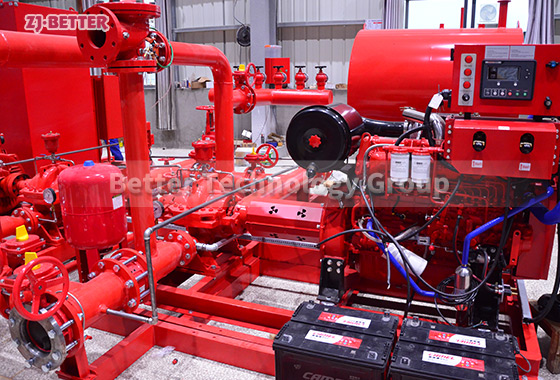

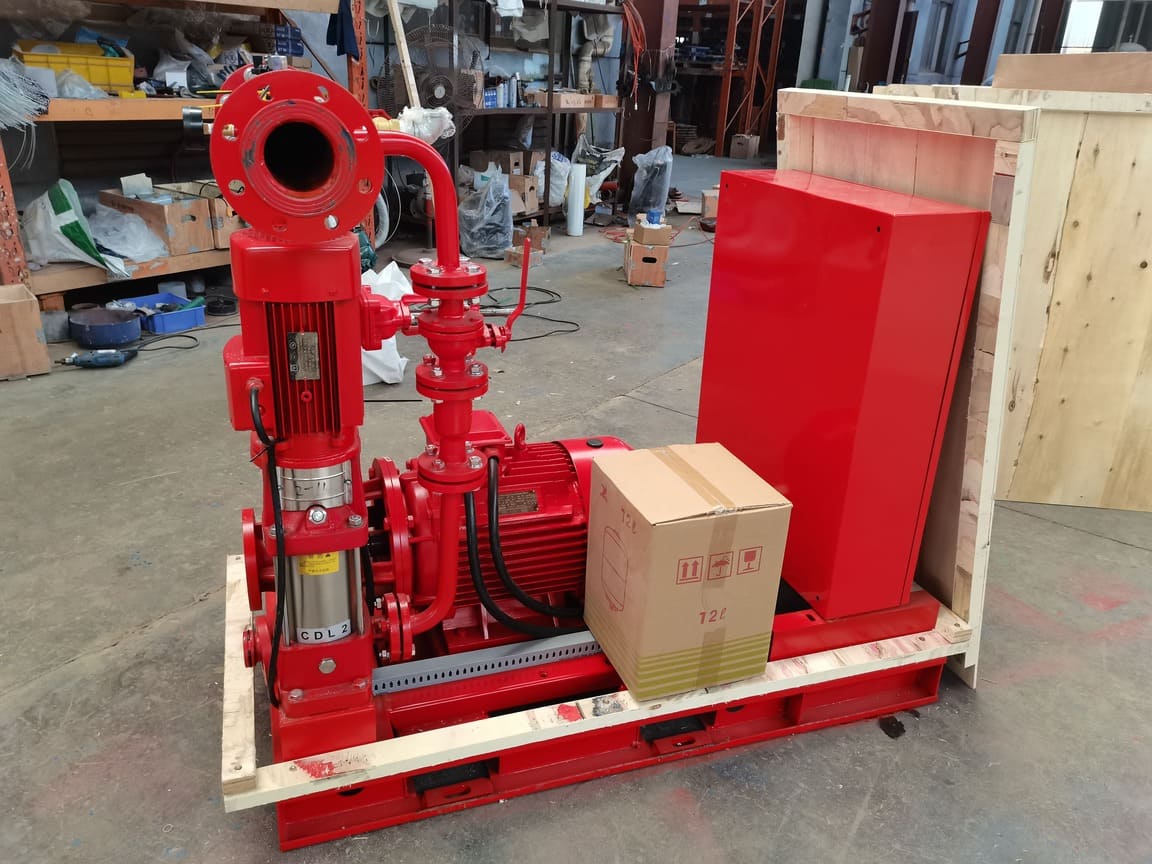

Proper installation is equally critical. Our professional team develops the best installation plan based on the site environment, ensuring tight pipe connections, smooth water flow, and stable electrical control system operation. The integration of intelligent control systems allows for automatic start-stop functions and remote monitoring, significantly improving response speed and operational convenience.

Finally, regular maintenance and inspection are essential for long-term efficiency. Our comprehensive after-sales services include routine inspections, spare parts replacement, and remote troubleshooting, ensuring the pump remains in peak condition.

Through scientific design, high-quality manufacturing, expert installation, and thorough maintenance, our fire pumps provide reliable fire protection solutions, helping to build highly efficient and secure fire suppression systems.

We specialize in the development and manufacturing of high-performance fire pumps, committed to providing stable, safe, and efficient fire water supply solutions. Our product range includes electric fire pumps, diesel engine fire pumps, dual-power fire pumps, and complete fire water supply systems, widely used in commercial buildings, industrial facilities, municipal projects, and petrochemical industries.

Our fire pumps are built with corrosion-resistant, high-strength materials to ensure long-term stability. With advanced hydraulic design and intelligent control systems, our products offer high efficiency, low energy consumption, and rapid response capabilities, automatically monitoring operational status to enhance fire system reliability.

From design to production, every step meets international standards and undergoes rigorous testing to ensure a reliable water supply in emergencies. With outstanding product quality and comprehensive technical support, our fire pumps are trusted by industries worldwide, delivering complete fire safety protection for our customers.