Uninterrupted Emergency Water Supply: Independent Operation of Diesel-Driven Fire Pumps

Discover the advantages of diesel-driven fire pump systems with independent operation, ideal for power outage scenarios and remote emergency response. Learn how these high-performance pumps ensure uninterrupted water supply for fire protection in industrial, commercial, and off-grid environments.

In the context of increasingly complex and diversified modern fire protection systems, ensuring uninterrupted emergency water supply during critical moments is a critical challenge that must be addressed in various scenarios, including industrial facilities, high-rise buildings, warehousing complexes, and remote areas. Diesel-driven fire pumps, as a type of water supply equipment with fully independent operational capabilities, are playing an increasingly vital role in numerous fire protection engineering projects. Compared to traditional electric fire pumps, the most distinctive feature of diesel fire pumps is their ability to operate independently of the power grid. Even in extreme emergency situations where power is completely cut off, they can rely on their own diesel engine systems to start and continue operating independently, thereby gaining critical response time during the early stages of a fire and ensuring the system’s overall risk-resilience.

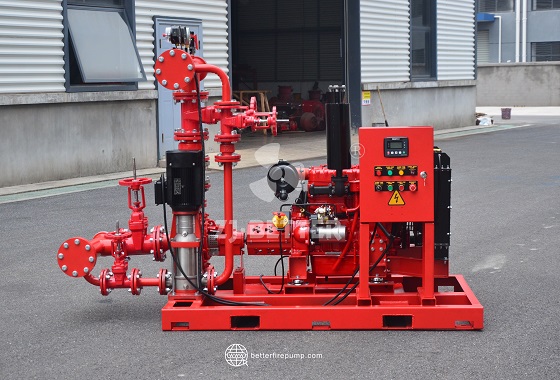

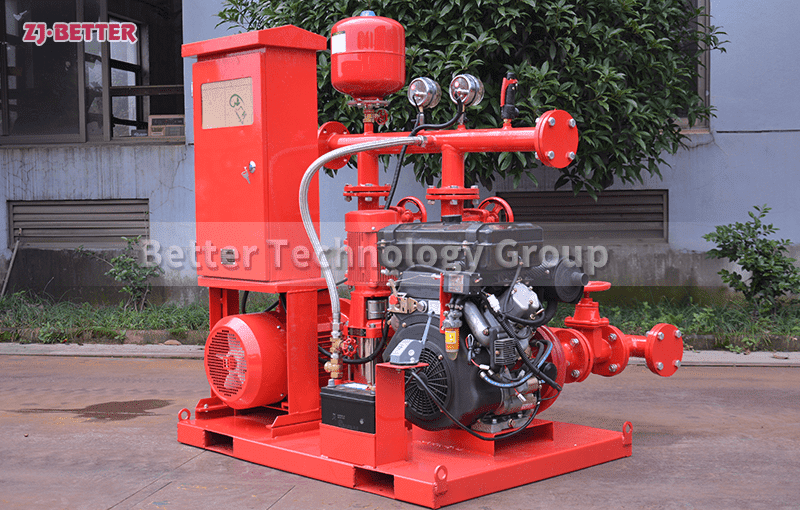

Diesel engine fire pump units typically consist of high-performance diesel engines, water pumps, couplings, bases, control cabinets, and fuel tanks. Their compact, integrated design not only facilitates transportation and installation but also significantly saves installation space, while achieving high functional integration. The diesel engine is ignited via an electric start system. Upon receiving a fire alarm signal or pressure change signal, the system automatically responds within seconds, rapidly starting the pump set and maintaining stable water pressure. Its flow rate and head parameters can be customized according to project requirements to meet the emergency water supply needs of different building structures and functional zones.

Every aspect of the diesel fire pump, from the fuel system to the cooling system, has been meticulously designed to withstand complex operating environments. For example, its built-in large fuel tank enables continuous operation for over two hours, providing robust logistical support for areas distant from power sources or unmanned zones; the engine features water-cooled or air-cooled cooling options, allowing flexible adaptation to climatic conditions; the control system supports remote monitoring and automatic alarm functions, enabling real-time oversight of pump set operation status and rapid fault resolution. Additionally, the exhaust system is constructed using high-temperature-resistant fireproof materials, effectively reducing the accumulation of heat generated by the engine in enclosed environments and enhancing overall equipment safety.

In high-risk operational environments such as industrial parks, power plants, petrochemical storage facilities, and tunnel construction sites, diesel-driven fire pumps, due to their structure that does not rely on the municipal power grid, can effectively avoid fire system failures caused by power outages, ensuring the system can be deployed immediately. Such pump units are also widely used in areas with unstable power supply or lacking power infrastructure, such as island infrastructure projects, remote townships, and military bases. Their high autonomy and high output power have earned them the market reputation of “guardians of extreme conditions.”

Technologically, modern diesel fire pumps utilize high-efficiency, low-emission diesel engines compliant with international environmental standards. Combined with optimized fuel injection systems and intelligent speed control devices, they ensure stable water output while significantly reducing fuel consumption and carbon emissions. Pump bodies are typically constructed from corrosion-resistant cast iron or stainless steel, with mechanical seal designs for the shaft seals to prevent leaks and extend service life. The entire system supports rapid maintenance, with extended engine maintenance intervals and easy pump body disassembly, significantly reducing daily operational costs.

Notably, some high-end diesel fire pumps now come equipped with intelligent cloud platforms, enabling remote access to real-time operational data, historical fault records, and maintenance alerts. This enhances the pump system’s intelligence and predictive capabilities, further instilling confidence in project stakeholders regarding system stability. Users can remotely start, stop, or set operational strategies via the platform, achieving true “unmanned automated operation.” .

Overall, diesel-driven fire pump sets are professional-grade equipment that combines strong power, independent operation, high safety, and intelligent monitoring capabilities. They are an indispensable key component in the design and upgrading of fire protection systems for various medium to large-scale projects. Not only do they ensure the continuity of emergency water supply, but they also enhance the overall response efficiency and operational convenience of the system through technological integration, serving as a reliable guarantee for the reliability of modern fire protection engineering systems.