In modern building fire protection systems, selecting a horizontal fire pump that truly meets project requirements plays a critical role. It not only serves as the power source for the fire water system but also constitutes the first line of defense for the entire emergency response capability. During the design phase, engineers must comprehensively consider factors such as building type (e.g., high-rise residential buildings, commercial complexes, industrial plants, data centers), system conditions (sprinkler water flow requirements, fire hydrant pressure needs, characteristics of backup water sources), and environmental factors (temperature, humidity, noise control, maintenance access), in order to make an accurate selection. Horizontal fire pumps are widely used in various buildings due to their horizontal arrangement of the pump body and motor, compact footprint, and low installation height, which facilitate equipment layer layout and maintenance access. Their flow rates range from hundreds to thousands of liters per minute, and their head can be adjusted to cover dozens to hundreds of meters according to design requirements, ensuring stable water supply to sprinklers and fire hydrants.

The motor of the horizontal pump adopts a high-efficiency design (IE3/IE4 grade), combined with an advanced cooling system and sealing structure, to enhance operational efficiency and service life. The intelligent control system enables automatic start/stop logic tracking, soft start control during high-speed operation to reduce impact inertia, automatic drainage for freeze protection after shutdown, and built-in multiple safety protections such as low-pressure protection, dry-run alarm, phase sequence protection, overload protection, and remote fault alarm interfaces, enhancing system stability. When integrated with a fire alarm control cabinet, it can be linked with the fire alarm system to automatically start the pump. Under PLC or intelligent fire protection platform control, it monitors operational curves, pump status, current/pressure data, etc., enabling remote monitoring and alarms, significantly enhancing system intelligence and visualization management capabilities.

In terms of structure, the horizontal fire pump adopts a cast pump body or composite casting technology, combining high-strength alloy materials with corrosion-resistant treatment (epoxy resin coating or stainless steel material). After sandblasting pretreatment, the coating thickness is ≥200μm, providing excellent rust and corrosion resistance; Critical wear-prone components, such as mechanical seals, bearings, and impellers, are sourced from imported brands or high-quality domestic alternatives to ensure long-term reliability under high-temperature, high-pressure, and high-frequency startup conditions. To reduce vibration and noise, spring-mounted vibration-damping bases are commonly used, combined with silent motors and rubber pads, keeping operational noise levels below 65 dB. This makes them particularly suitable for residential areas and environments with strict noise restrictions, such as libraries and hospitals.

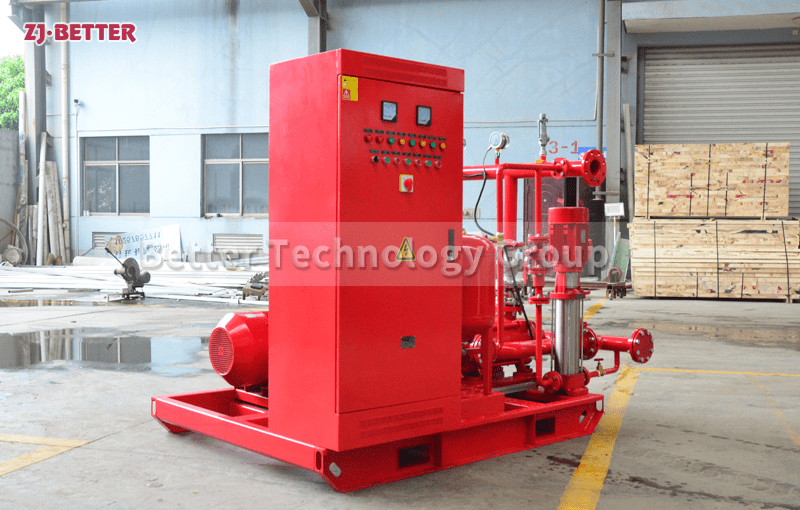

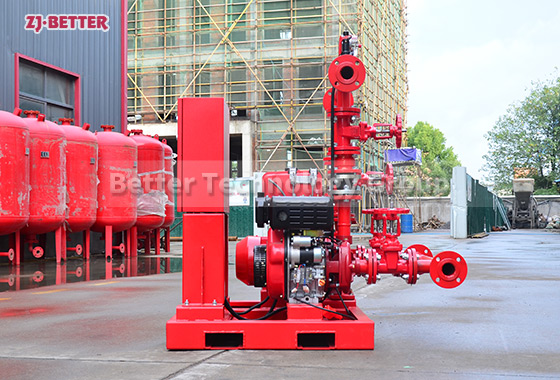

At the system configuration level, standard configurations (single pump + control cabinet + bypass pipe + pressure gauge) or complex engineering configurations (dual pumps in parallel, bypass pump, one operating at normal pressure and one as a standby, or dividing the control cabinet into a main cabinet and a mechanical pump control cabinet, with manual/automatic mode switching and calibration functions) can be provided according to project requirements. High-end configurations can include variable frequency controllers to adjust pump speed according to real-time demand, further enhancing energy efficiency and emissions reduction. This also minimizes startup vibration and sudden changes in current, significantly reducing mechanical wear and grid impact.

All pump sets undergo rigorous factory performance testing (including hydrostatic pressure testing, flow curve testing, pressure calibration testing, three-phase balance testing, and insulation resistance testing), with performance test reports issued. They strictly comply with UL/FM/CE/NFPA 20 standards, meeting international and regional regulatory requirements. Upon shipment, a complete set of technical documentation is provided, including electrical schematics, control logic diagrams, disassembly and maintenance manuals, technical parameter reports, noise reports, etc., to meet customer and engineering firm requirements for comprehensive documentation.

During the installation and commissioning phase, we will dispatch technicians with fire protection engineering qualifications to provide on-site guidance, strictly supervising foundation embedded hole positioning, pump base bolt tightening, pipeline preheating, equipment alignment, and electrical control cabinet grounding to ensure smooth system startup. We also provide initial trial operation services (5 cold starts + 2 hours of continuous hot operation). After delivery, a one-year maintenance plan will be established, including monthly inspections, quarterly shaft seal inspections, semi-annual pump body vibration analysis and coupling alignment checks, and annual oil and seal replacements. Long-term maintenance can extend the equipment’s service life to over 15 years.

In terms of cost control, although high-spec systems have relatively higher initial investment costs, their lifecycle costs are significantly lower than standard models when evaluating long-term operational costs, energy consumption, failure rates, and maintenance expenses. Over the same usage period, they can save 20–30% of total costs. Additionally, due to its modular design, future project upgrades (such as adding fire pump sets, replacing control cabinets, or upgrading variable frequency components) will only cost 30% of the cost of selecting a new system.

Selecting a mature, intelligent, compact, and reliable horizontal fire pump not only provides robust fire emergency protection for building projects but also represents a comprehensive consideration of professional technology, safety compliance, and sustainable operations, reflecting the confidence of contractors, design institutes, and property owners. By clearly defining project objectives from the outset, collaborating closely on system selection, strictly enforcing testing protocols, adhering to standardized installation and commissioning procedures, and providing comprehensive post-installation maintenance services, the system minimizes construction risks and operational hazards, achieving the core objective of ensuring the “sustainable protection” of the building’s fire protection system. The above analysis delves into the design principles, structural advantages, testing standards, installation procedures, and operational maintenance recommendations for horizontal electric fire pumps, aiding customers in making informed decisions when selecting products to ensure the efficient, stable, and safe operation of the final system.