No Foot Valve, No Manual Priming: Why Modern Fire Systems Rely on Self-Priming Pump Technology

The self-priming fire pump eliminates the need for foot valves and manual priming, featuring fast startup, strong suction capacity, and compatibility with smart control systems. Ideal for industrial facilities, municipal water supply, and emergency firefighting, it enhances system response and reliability.

In modern fire protection systems, rapid response, efficient water supply, streamlined operation, and equipment reliability have become critical criteria for evaluating pump performance. Traditional fire pumps—especially standard centrifugal pumps—often encounter technical challenges such as requiring manual priming, relying on foot valves, and experiencing delayed startup. These issues can significantly hinder emergency response effectiveness. To address these limitations, horizontal self-priming pumps have emerged as a preferred solution due to their structural advantages: no foot valve required and no manual priming needed.

Self-priming pumps are specially engineered to expel air and draw water automatically during startup, using a vacuum effect created by the residual liquid inside the pump casing. This allows the pump to draw water from an external source within seconds, eliminating the need for pre-filling or manual intervention. This is especially valuable in emergency scenarios with limited personnel or urgent water supply needs.

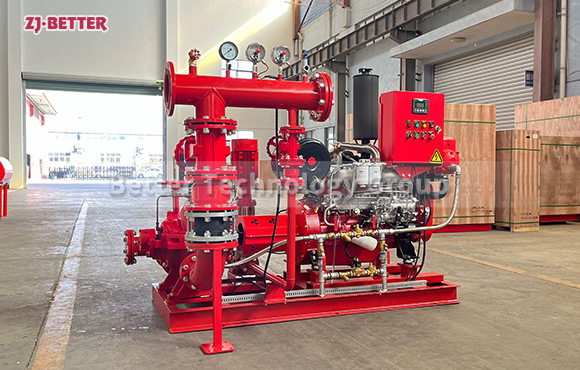

The pump shown in the image features a high-strength cast iron body and an optimized internal hydraulic design that allows a suction lift of up to 6–8 meters. It can complete priming within 10 to 30 seconds, making it ideal for use in low-level water sources or remote water collection points. The direct-coupled motor design ensures a compact footprint and simplified installation, which is particularly useful in fire water tanks at industrial sites, municipal water systems, emergency vehicle pumps, and temporary construction fire systems.

This pump delivers stable performance, with a mechanical seal that ensures leak-free long-term operation. Its internal flow path and high-efficiency impeller contribute to superior hydraulic performance and strong anti-cavitation capability. Moreover, when paired with an intelligent control panel, it can offer automatic start-stop, remote monitoring, and pressure feedback, enhancing its role in smart firefighting infrastructures.

From a compliance standpoint, this model has passed multiple national fire safety certifications and ISO quality standards. It can be integrated with sprinkler systems, hydrant networks, pressure stabilizers, and other components, making it an ideal solution for smart fire systems and unattended pump stations.

As the demand for “rapid response + simplified systems + smart control” continues to grow, horizontal self-priming fire pumps will remain a key player. Their efficient design—eliminating the need for foot valves and manual priming—is revolutionizing traditional water supply concepts and driving the evolution of modern fire protection systems toward higher efficiency, automation, and reliability.