Variable Frequency Pressure Control in Integrated Fire Water Stabilization Systems

The integrated fire pressure stabilization system features advanced variable frequency constant pressure control technology, offering intelligent pressure regulation, energy efficiency, and remote monitoring. It is widely used in high-rise buildings, commercial complexes, and public facilities to ensure stable pressure and rapid emergency response.

In modern fire protection systems for urban infrastructure and large-scale buildings, water supply stability, reliability, and rapid response capability are critical performance indicators. Traditional fire pump setups using fixed-speed pumps or single-pump configurations often fail to adjust dynamically to changing system demands. This results in unstable water pressure, higher energy consumption, and delayed supply during emergencies. With the advancement of control technologies, variable frequency constant pressure (VFCP) systems have become a core innovation in integrated fire pressure stabilization solutions, significantly enhancing performance and operational efficiency.

The VFCP system utilizes high-precision pressure sensors and intelligent frequency converters to continuously monitor outlet pressure and automatically adjust the pump’s operating frequency in real time. When demand fluctuates or pressure changes, the inverter instantly modifies the pump speed to maintain a consistent output pressure. This ensures that the fire pipeline network is always in a ready-to-act state. During periods of low demand or non-emergency hours, the system reduces speed or enters sleep mode, dramatically reducing energy consumption and wear on mechanical components.

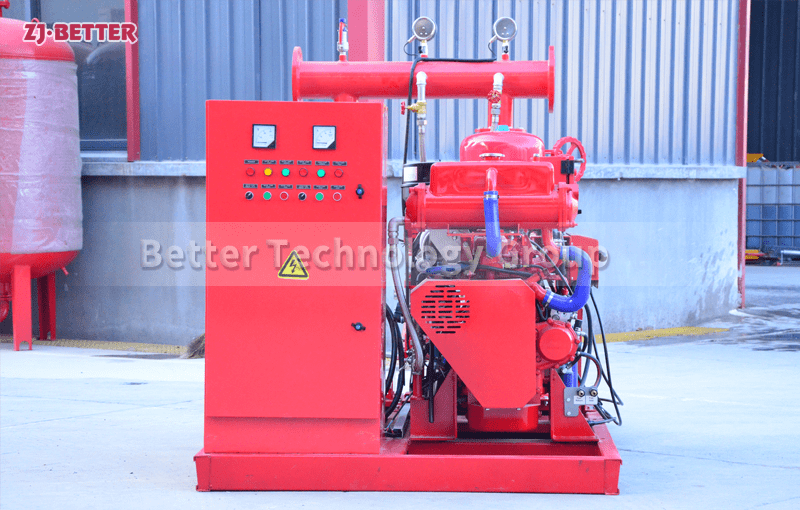

Structurally, this solution typically integrates multiple vertical multistage pumps, a frequency control cabinet, a stainless-steel air pressure tank, check valves, pressure gauges, and smart control cables into a modular and compact design. Pumps are configured in a main + standby mode, enabling automatic alternation and failover operations. This eliminates prolonged single-pump stress, extending the life span of the entire unit. All components are made from corrosion-resistant materials to ensure long-term durability in diverse water quality environments.

The system also supports remote monitoring and alarm features. Through RS485 communication or Ethernet connectivity, it can synchronize operational data with a central fire control platform. If issues such as abnormal pressure, motor overload, phase loss, or leakage are detected, the controller triggers automatic alarms and switches to safe mode, ensuring uninterrupted supply and fast recovery.

From an energy-saving standpoint, VFCP technology offers over 30% power reduction compared to traditional fixed-speed systems. By dynamically adjusting pump speed based on real-time flow and pressure demands, the system avoids overcapacity operation while maintaining optimal pressure—substantially lowering operational costs. This aligns perfectly with modern trends in green building and sustainability.

Widely adopted in residential complexes, high-rise buildings, metro stations, tunnels, commercial centers, airports, and hospitals, VFCP-based fire pump systems meet both long-term standby pressure demands and rapid high-pressure response in emergencies. With its intelligent, modular, and energy-efficient design, this technology exemplifies the future direction of fire protection equipment innovation.