Maximized Space Utilization: Advantages of Compact Diesel Fire Pump Systems in Modern Industrial Facilities

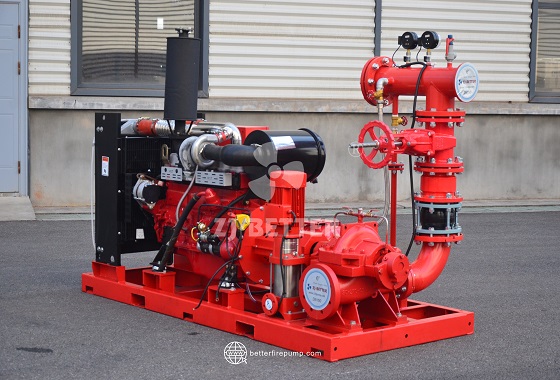

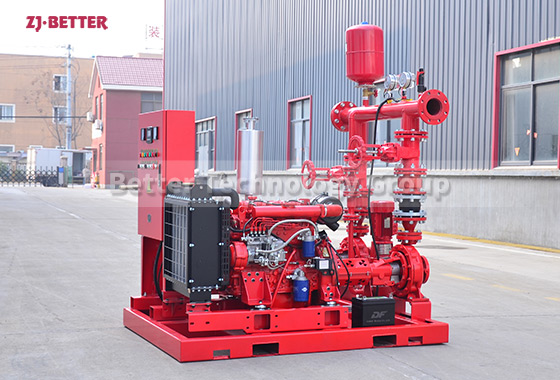

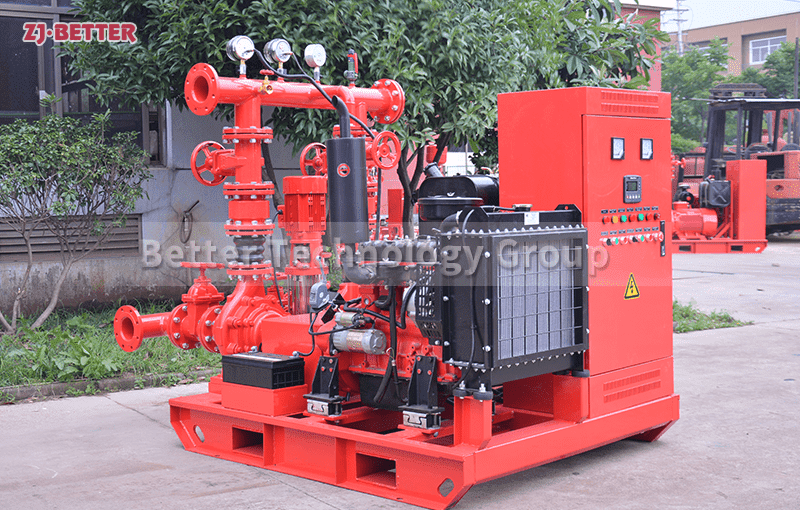

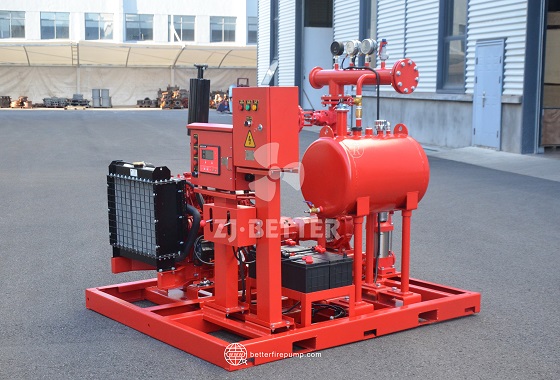

The dual-power fire pump system combines diesel engine and pressure-stabilized electric control for enhanced firefighting performance and reliability in high-risk industrial, commercial, and remote locations.

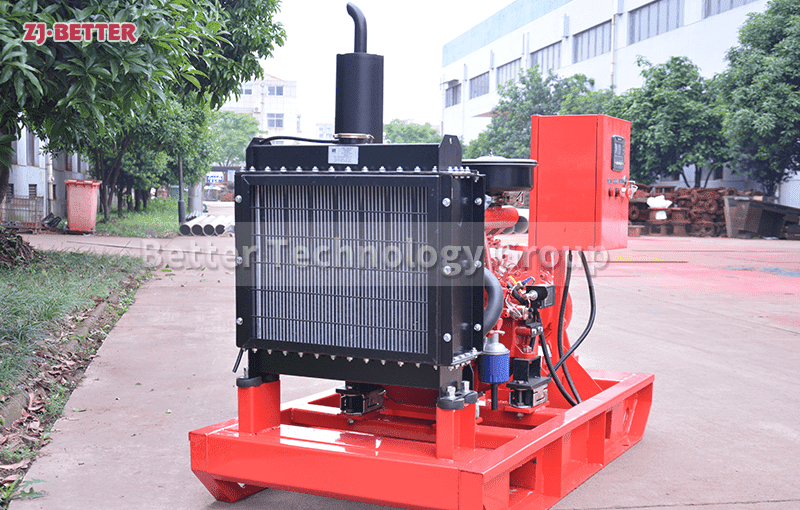

In modern industrial buildings, fire protection systems must not only meet stringent safety standards but also balance space efficiency and operational convenience. As urban industrialization and high-density building trends continue to evolve, the limitations of traditional large-scale fire pump systems—such as space requirements, installation flexibility, and maintenance complexity—have become increasingly apparent. Compact diesel fire pump systems have emerged as a solution, offering advantages such as compact design, reliable performance, and high integration, making them an important choice for upgrading fire safety in new-generation industrial facilities. First, compact diesel fire pump systems integrate key components such as engines, pumps, control systems, fuel systems, and cooling systems into a single robust base through modular design, significantly reducing floor space requirements. This design is particularly suitable for industrial plants, underground machine rooms, or renovation projects with limited space, enabling smooth installation without major structural adjustments. Additionally, the system is equipped with soundproof enclosures, thermal insulation structures, and multiple vibration-damping measures to effectively control operational noise and heat radiation, enhancing overall workplace comfort. Secondly, the system is powered by a diesel engine, eliminating the need for reliance on the power grid. It can be quickly started and continue to operate even during power outages, significantly enhancing the independence and reliability of fire emergency response. Its automatic control cabinet enables intelligent operations such as one-button start/stop, self-diagnosis, and real-time monitoring of operational data, further reducing manual intervention and improving operational efficiency. Additionally, the entire system is pre-tested and assembled at the factory, requiring users to only complete piping and electrical connections on-site before use, significantly reducing installation time and simplifying engineering complexity. In terms of performance, the compact diesel fire pump system is equipped with a high-efficiency centrifugal pump. After hydraulic model optimization, it can achieve stable output of high flow rates and high head, meeting diverse firefighting requirements across various industrial applications. The system can also be customized with optional dual pumps, pressure-stabilizing pumps, alarm devices, and remote monitoring modules to provide a more comprehensive solution, ensuring efficient response in firefighting tasks across critical industries such as chemicals, energy, and manufacturing. In terms of maintenance, the equipment features a compact yet well-organized structure with independently partitioned functional modules, facilitating disassembly, inspection, and replacement of components. The system is standardly equipped with fuel filters, water temperature sensors, oil pressure sensors, and other monitoring components, which provide real-time feedback on operational status, helping maintenance personnel promptly identify potential issues and take measures to prevent faults from escalating. Additionally, some products support remote networking functionality, enabling 24/7 monitoring and parameter adjustments via mobile devices or computers, thereby enhancing management efficiency. From an environmental perspective, the compact diesel fire pump system uses low-emission diesel engines that comply with the latest environmental regulations. Combined with an efficient combustion system and exhaust treatment devices, it effectively reduces harmful emissions during operation, balancing firefighting efficiency with environmental friendliness. The overall coating uses high-corrosion-resistant spray materials to ensure the equipment operates stably in harsh environments such as high humidity, high salt content, and high dust levels, making it an ideal choice for special locations like coastal factories, underground garages, and port warehouses. Finally, with the development of industrial intelligence, the compact diesel fire pump system is also evolving toward integration with the Internet of Things, data collection, and cloud platforms, providing enterprises with higher-level safety management tools. Through big data analysis and remote collaboration functions, users can analyze and predict equipment operation conditions in different scenarios, achieving more scientific risk assessment and decision-making deployment. In summary, compact diesel fire pump systems, with their outstanding spatial adaptability, stable operational performance, intelligent management methods, and environmentally friendly design concepts, are becoming an important upgrade direction for modern industrial building fire protection systems. Whether for new construction projects or retrofits of existing facilities, they offer the advantages of high integration, high performance, and high reliability, providing continuous, safe, and efficient fire protection for industrial production environments.