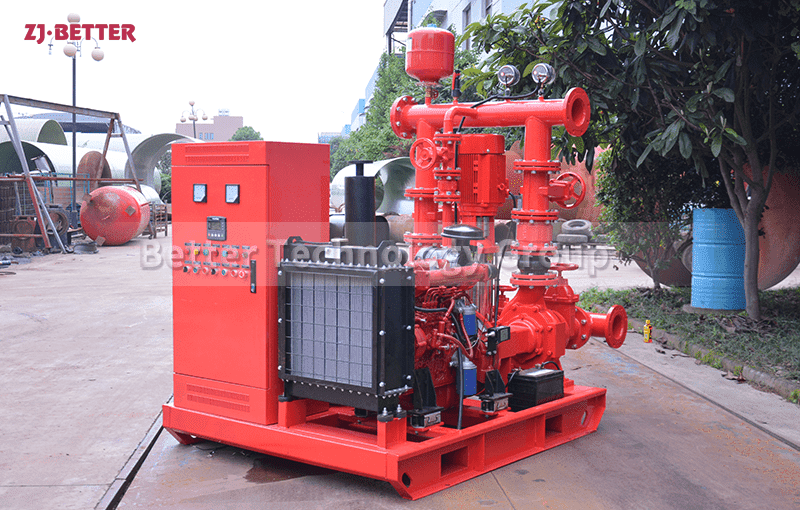

Small flow EDJ pump set

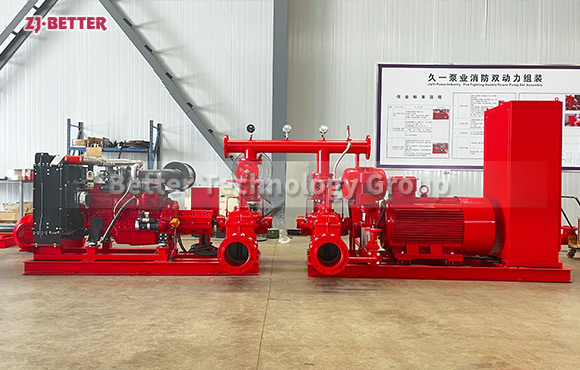

Electric pump + diesel pump + joceky pump

The three pumps are automatically started and stopped. When the joceky pump detects that the electric pump cannot operate normally, the diesel engine pump will start automatically. Can also be used, the fire pump set is widely used in various emergency firefighting occasions.

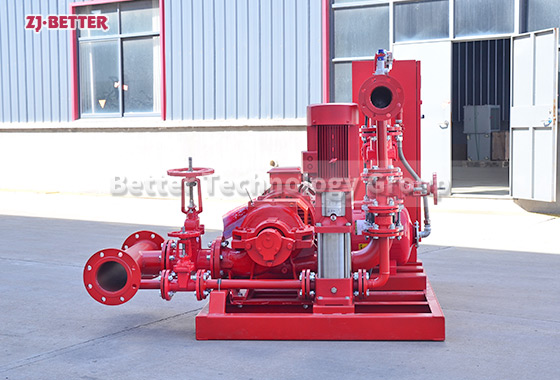

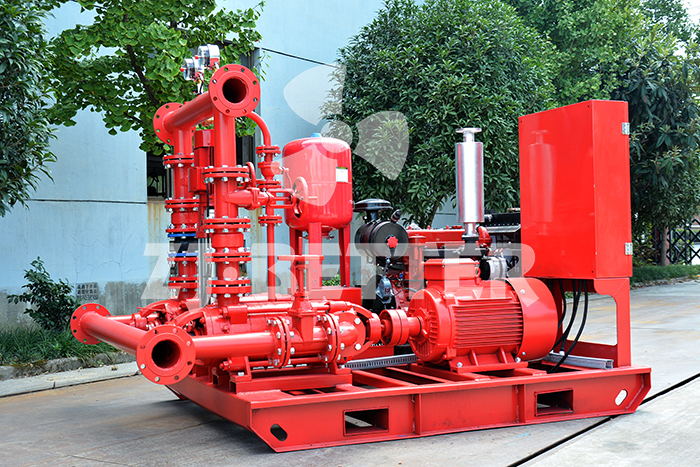

Electric pump + diesel pump + joceky pump

The three pumps are automatically started and stopped. When the joceky pump detects that the electric pump cannot operate normally, the diesel engine pump will start automatically. Can also be used, the fire pump set is widely used in various emergency firefighting occasions.

The ISW horizontal electric fire pump is composed of two parts, the motor and the pump. The pump and the motor are coaxial, which simplifies the connection of the pipeline. The pump inlet and outlet are on the same horizontal axis, and the diameter and specifications are the same. . The pump is provided with a mounting base, which is easy to install and increases the stability of the pump operation. The pump seal adopts mechanical seal, which has the characteristics of reliable sealing and no leakage.