Intelligent Fire Pump System Tailored for Compact and Mid-Sized Spaces

Discover the ideal fire pump solution for compact and mid-sized buildings with our intelligent electric fire pump system. Featuring a space-saving vertical design, smart controls, and high efficiency, it’s perfect for residential, commercial, and industrial fire protection needs.

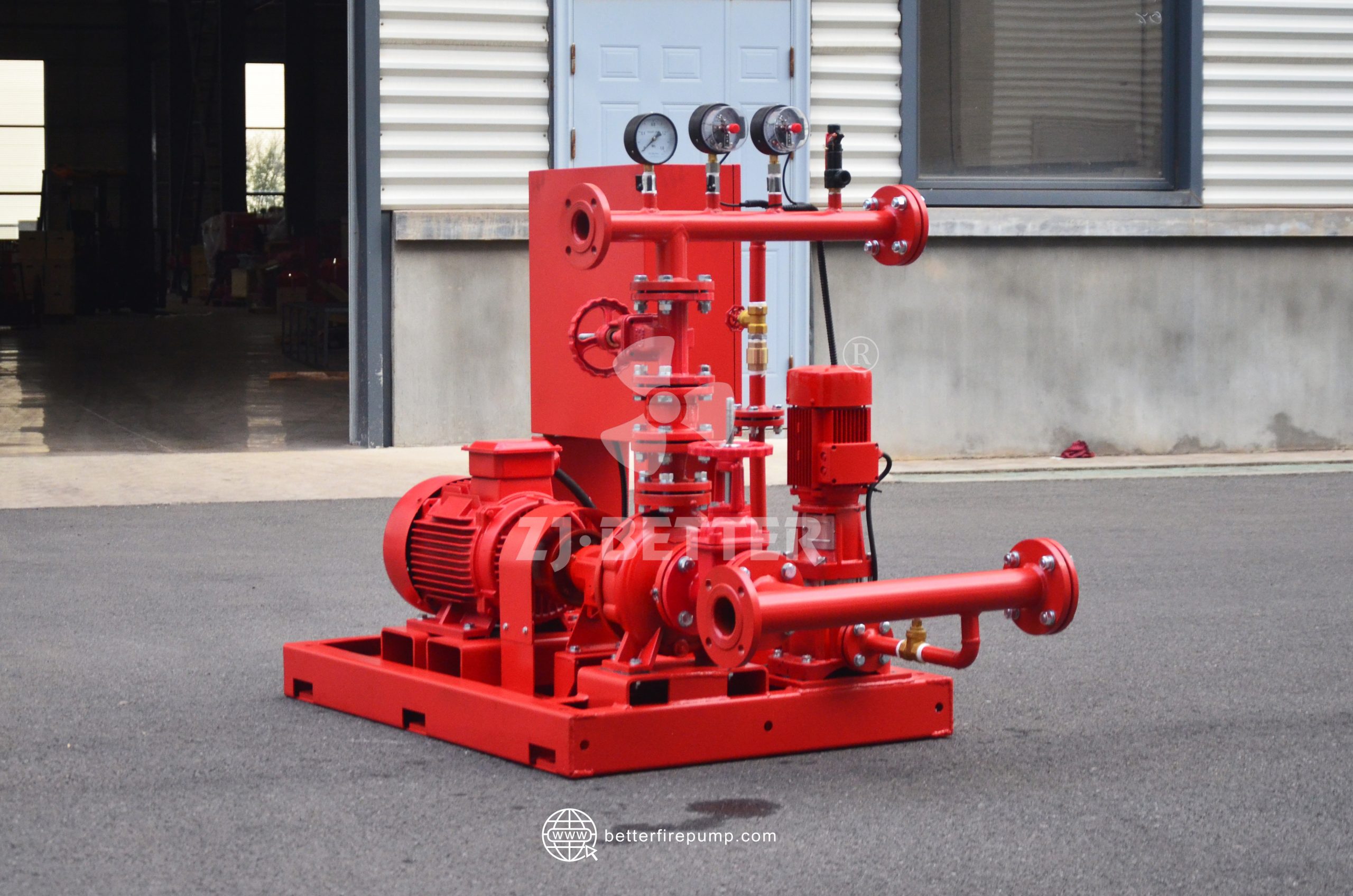

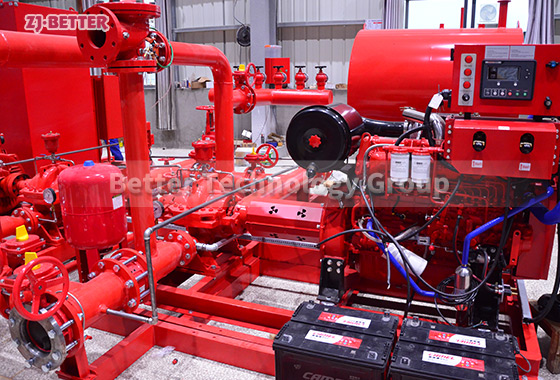

In modern urban buildings and industrial applications, space constraints present a critical challenge in fire protection system design. This is particularly true in compact environments such as small to medium-sized buildings, underground parking lots, commercial complexes, and factory workshops, where ensuring efficient and reliable fire water supply is paramount to project safety. To address this, we have introduced a smart electric fire pump system specifically tailored for small and medium-sized spaces. This system features a compact, well-designed structure with vertical installation, saving floor space while facilitating maintenance and equipment replacement. The core power unit employs high-efficiency, energy-saving motors combined with multi-stage or single-stage fire pumps, equipped with an intelligent control system to enable automatic start/stop, fault alerts, and remote interconnection functions, significantly enhancing the response speed and operational efficiency of the fire protection system. The control cabinet is designed with standard industrial-grade protection and features multiple control interfaces, enabling integration with building automation systems (BAS), fire alarm systems (FAS), and other systems to achieve intelligent fire safety interconnection and response. The pump body is made of corrosion-resistant high-strength cast iron or stainless steel, and variable frequency control configurations are available upon project requirements to ensure efficient operation under varying water pressure conditions, significantly reducing energy waste. The entire system complies with international and domestic fire safety standards such as NFPA 20 and GB 27898, making it suitable for various building scenarios including residential communities, hospitals, schools, office buildings, warehouses, and supermarkets. In addition to optimizing technical performance, we have also thoroughly considered equipment dimensions and transportation/installation logistics. The entire system can be integrated onto a standard base, enabling transportation via forklift and crane integration. On-site installation only requires connecting the inlet and outlet water pipes and power supply, allowing immediate use and significantly reducing construction time and labor costs. Additionally, we offer comprehensive customization services, enabling customers to select different pump configurations based on building layout, including flow rate and head, as well as integrate functional modules such as pressure-stabilizing pumps, sprinkler pumps, and jockey pumps to create a comprehensive fire protection water supply solution. While ensuring the stable operation of the system, the intelligent monitoring module can also monitor key data such as flow rate, pressure, current, and voltage in real time, and generate trend analysis through data recording to assist managers in daily maintenance and safety assessments. Additionally, the system supports remote control via a mobile app or computer, enabling managers to promptly monitor equipment status and achieve “remote warning and proactive intervention,” truly transitioning from “post-incident response” to “pre-incident prevention.” In terms of energy conservation and environmental protection, this intelligent fire pump system supports multi-speed operation control, automatically switching between operating modes based on actual water demand. This ensures fire response capabilities while minimizing energy consumption, aligning with industry goals for green buildings, carbon peaking, and carbon neutrality. We understand that the on-site environment, system requirements, and budget conditions vary for each project. Therefore, through modular design and flexible manufacturing processes, we create customized solutions that are truly tailored to customer needs and are plug-and-play ready. With a strong R&D team and extensive production experience, our intelligent electric fire pump system has been widely adopted in projects across multiple countries and regions worldwide, earning high recognition from customers. Looking ahead, we will continue to prioritize technological innovation, driving the evolution of fire pump systems toward greater intelligence, efficiency, and environmental sustainability. Selecting a smart fire pump solution tailored for small to medium-sized spaces not only enhances building safety standards but also significantly reduces operational space and costs, empowering project operations and safeguarding urban fire safety.