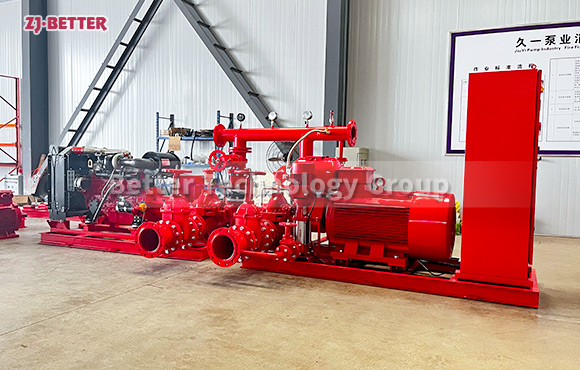

Diesel Driven Fire Pump Package for Large Building Fire Protection Systems

The diesel-driven fire pump unit adopts an independent power design, with large flow, high head and continuous operation capabilities. It is suitable for fire protection systems of large buildings and can continuously ensure the reliability and safety of fire water supply under power failure and high load conditions.

Diesel-driven fire pump units are key water supply equipment in large building fire protection systems, primarily responsible for providing a continuous, stable, and high-intensity water source to the entire fire protection network during a fire. Their core advantages lie in their independent power drive and highly integrated structural design, enabling reliable operation even in complex environments and emergency situations. These units typically consist of a diesel power system, fire pump body, cooling and heat dissipation devices, fuel system, piping and valve assemblies, monitoring instruments, and a centralized control system. Integrated installation via a unified heavy-duty base not only ensures overall structural strength and operational stability but also significantly simplifies on-site construction and system integration processes. They are particularly suitable for high-rise buildings, commercial complexes, large factories, warehousing and logistics centers, airports, data centers, and other building projects with extremely high requirements for continuous and safe fire water supply. Diesel drive is one of the unit’s most prominent performance advantages. In the event of a power outage, unstable power system, or power supply damage due to a fire, the equipment can still quickly start and operate using its own power system, fundamentally avoiding the risk of fire protection system failure due to power failure and providing reliable water supply for large buildings in extreme situations. In terms of performance design, this fire pump unit scientifically matches the diesel power output with the pump body’s hydraulic structure, enabling the system to achieve high flow rate, high head, and stable pressure output under rated operating conditions. It can simultaneously meet the combined operation requirements of automatic sprinkler systems, indoor and outdoor fire hydrant systems, and other fire-fighting water facilities. Even under conditions of simultaneous operation at multiple points, long-distance water delivery, or high-rise vertical water supply, it maintains excellent water pressure stability and flow continuity. The pump body employs an optimized flow channel design and a high-efficiency impeller structure, improving hydraulic efficiency while reducing energy loss, ensuring good economy and reliability during long-term operation. Considering the need for continuous water supply in large building fire protection systems, this unit has been significantly enhanced in terms of durability and continuous operation capability. The diesel power system has ample torque reserves and load adaptability, maintaining stable speed even under high load conditions, providing continuous and balanced power support to the fire pump, thus ensuring uninterrupted fire extinguishing. The cooling system is also designed with long-term operation as its core objective. Through an efficient heat dissipation structure and a rational airflow or liquid cooling layout, it ensures that the power system remains within a reasonable temperature range during continuous operation, reducing the risk of performance degradation or failure due to overheating. In terms of structure and materials, the complete unit is designed and manufactured strictly according to industrial-grade application standards. Key pressure-bearing components are made of high-strength materials and undergo anti-corrosion and anti-rust treatment to adapt to humid, high-temperature, dusty, or poorly ventilated pump room environments, ensuring the equipment maintains good condition during long-term standby or periodic operation. The control system, as the central operating system of the entire unit, integrates start-up control, operation monitoring, parameter display, and multiple protection functions. It can realize automatic and manual control modes, meeting the needs of large building fire protection systems for centralized management and reliable response. When the system detects abnormal operating conditions, it can promptly issue alarm signals and take corresponding protective measures, thereby improving overall operational safety. Considering the operational characteristics of large building fire protection equipment—”standby during peacetime and high-intensity operation during critical moments”—this diesel-driven fire pump unit has been specifically optimized for startup reliability. Through a stable startup system and a rational fuel supply design, it ensures that the equipment can start quickly and rapidly enter a stable operating state even after prolonged periods of inactivity. The system also boasts significant advantages in engineering adaptability, allowing for flexible configuration of single pumps, main/standby pumps, or multi-pump parallel systems according to building size and fire protection regulations, meeting different flow rate and pressure requirements, while easily integrating with existing fire protection piping networks. The modular design makes subsequent maintenance and repair more efficient, with a rational layout of key components and ample maintenance space, effectively reducing maintenance difficulty and operating costs. In summary, the diesel-driven fire pump unit, with its independent power advantage, excellent high-flow-rate and high-lift performance, stable continuous operation capability, and high adaptability to the complex conditions of large buildings, has become an indispensable core piece of equipment in large building fire protection systems. It not only provides powerful water supply support for firefighting operations in emergencies but also builds a solid and reliable foundation for building fire safety during long-term operation and standby.