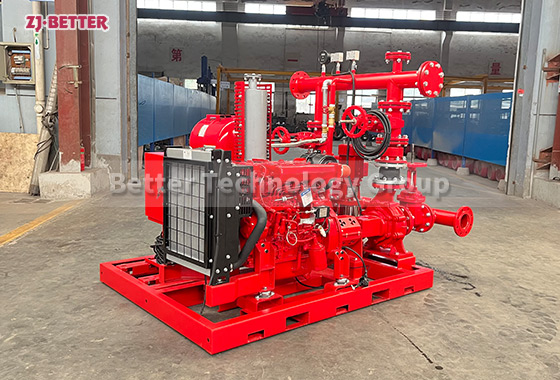

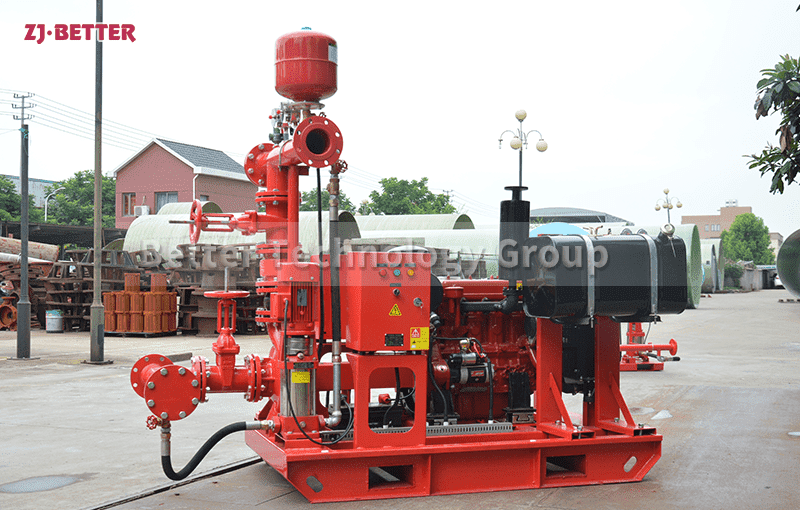

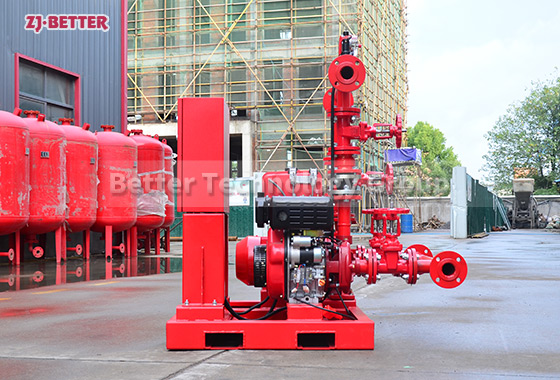

High Protection Level Fire Pump Equipment: Suitable for Extreme Conditions

High-protection-level fire pumps possess superior waterproof, dustproof, and corrosion-resistant properties, making them suitable for complex environments such as docks, power plants, tunnels, and oil depots, providing efficient and stable fire water supply. Employing an intelligent control system, dual-power drive, and energy-saving design, they support remote monitoring and customized configurations, ensuring continuous operation in extreme weather conditions, meeting international fire protection standards, and providing reliable fire safety solutions for various industrial and municipal projects.

High-protection-level fire pump equipment is a high-performance fire water supply system designed specifically for complex and harsh environments. It plays a vital role in industrial areas, oil depots, docks, power plants, tunnels, airports, and areas far from urban water supply networks. The core advantages of this equipment lie in its superior protection capabilities and consistently stable performance. It maintains efficient operation in high-temperature, low-temperature, humid, dusty, salt spray, or highly corrosive environments, providing safe and reliable fire water supply for various buildings and facilities. High-protection-level fire pump equipment employs a highly weather-resistant structural design. The pump body and piping system undergo anti-corrosion coating treatment, possessing excellent waterproof, dustproof, rustproof, and shockproof characteristics. The entire system is typically assembled in a protective casing or containerized structure. The casing undergoes sandblasting and electrostatic spraying processes, achieving a protection level of IP55 or even IP65, effectively preventing rainwater and dust from entering the system. Its inner lining features heat insulation and sound insulation design, reducing the impact of ambient temperature on equipment operation and lowering noise pollution, meeting the requirements for quiet operation in industrial parks, residential areas, and other locations. The core components of the equipment are made of high-strength alloy materials. The pump body is precision-machined, and the impeller is made of stainless steel or bronze, possessing excellent wear and corrosion resistance. It can operate for extended periods in media containing trace impurities or salt without affecting efficiency. The motor is designed with a fully enclosed structure, featuring moisture-proof, dust-proof, and overheat protection, ensuring stable operation in high-humidity environments. The control system uses an intelligent control panel, enabling automatic start/stop, pressure monitoring, flow regulation, fault alarms, and remote monitoring. When the system detects a pressure drop or fire signal, it can automatically start the pump unit to supply water, ensuring immediate response to fires. The control cabinet adopts a structure design with a protection rating of IP54 or higher, equipped with isolated electrical components and explosion-proof wiring to prevent system failures caused by moisture or short circuits in the electrical components, ensuring the long-term safe operation of the fire protection system. High-protection-level fire pump equipment not only emphasizes the reliability of the protective structure but also the high efficiency of operational performance. Its design flow rate and head are precisely calculated, allowing for flexible configuration of single-pump or multi-pump combinations according to project requirements. The multi-pump system employs an alternating operation of the main and standby pumps to ensure continuous water supply. Even in the event of maintenance or failure of a single pump, the system can automatically switch operation without affecting the overall fire water supply. The equipment offers flexible starting methods, employing electric motor drive, diesel engine drive, or a dual-power switching design to ensure independent water supply even in the event of power outages, extreme weather, or remote areas without external power. The diesel-driven fire pump is equipped with a high-efficiency engine and a large-capacity fuel tank, allowing for continuous operation for several hours, suitable for long-term water supply tasks in emergency scenarios. An optional automatic preheating system ensures rapid start-up in low-temperature environments, enabling reliable operation even in areas with temperatures as low as -20 degrees Celsius. In addition to the advantages of its power system and protective design, the equipment is equipped with an intelligent monitoring module, enabling remote status monitoring via wireless or wired connections. Users can view real-time pump operation data, including parameters such as flow rate, pressure, speed, temperature, and fuel status, through a computer or mobile terminal, thus achieving intelligent operation and maintenance and remote management. The system can be preset with multiple operating modes, such as routine inspection, emergency water supply, automatic switching, and timed operation, to meet the fire management needs of different scenarios. In terms of maintenance, the high-protection-level fire pump features a compact structure and reasonable layout, with easy disassembly and assembly of components for convenient daily inspection and maintenance. The pump body is equipped with exhaust and drainage ports, enabling quick cleaning and sewage discharge, reducing the impact of deposits on pump efficiency after long-term operation. The lubrication system employs a fully automatic circulating lubrication method, ensuring that bearings and transmission components maintain good lubrication under high loads, extending their service life. The control system has self-diagnostic and recording functions; when abnormal voltage, excessive temperature, or unstable water pressure is detected, it will automatically alarm and record operating data, facilitating rapid problem identification and mitigation by technicians. Regarding energy efficiency, this fire pump uses a high-efficiency energy-saving motor and optimized hydraulic design, improving pump efficiency by more than 15% compared to traditional products. Through frequency conversion control technology, the system can automatically adjust operating power according to actual water demand, avoiding energy waste. It can operate at low speed in non-fire conditions, and automatically switches to rated operating mode upon detecting a fire alarm signal, achieving both rapid response and energy saving. The equipment complies with international fire protection standards, such as NFPA20, EN12845, and ISO9001 quality system requirements, ensuring traceable performance in various fire protection projects. This high-protection-level fire pump has a wide range of applications, especially suitable for fire water supply systems in environments with high humidity, high salt spray, and high dust. Examples include coastal docks, shipyards, petrochemical bases, power plants, underground tunnels, warehousing and logistics centers, and large manufacturing plants. For fire protection systems requiring all-weather protection and continuous operation, this equipment maintains a stable water supply even in extreme weather conditions, serving as a core guarantee for the system. The high protection level design not only extends the equipment’s service life but also significantly reduces maintenance frequency and costs, helping users achieve long-term economic benefits. The equipment also supports customized services, allowing for personalized design based on the client’s project environment, pressure requirements, installation space, and power supply conditions. Whether vertical, horizontal, or containerized, it can be flexibly configured to adapt to different engineering layout requirements. Through modular design, users can quickly complete installation and commissioning, shortening the construction cycle. Each unit undergoes rigorous performance testing before leaving the factory, including flow rate testing, pressure testing, sealing testing, and protection level testing, ensuring that every unit is ready for use upon arrival at the site. In summary, high-protection-level fire pump equipment, with its excellent protective performance, powerful water supply capacity, intelligent control system, and highly reliable operation, has become an indispensable piece of equipment in industrial and municipal fire protection systems. It not only operates stably under extreme conditions but also achieves energy-saving, efficient, and safe fire water supply management, providing sustained safety protection for various buildings and facilities worldwide. It is an irreplaceable high-end solution in modern fire protection systems.