Analysis and Operational Advantages of Electric Fire Pump Automatic Monitoring System

The automatic monitoring system for electric fire pumps has advantages such as efficient and intelligent control, remote monitoring and energy-saving operation. It can realize automatic start and stop, pressure regulation and fault alarm, ensuring stable and reliable fire water supply. It is widely used in fire safety systems of high-rise buildings, factories, subways and public facilities.

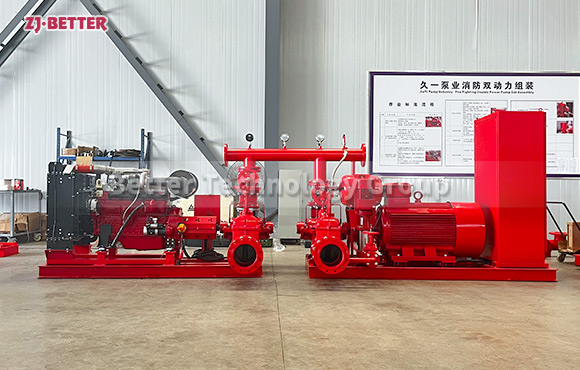

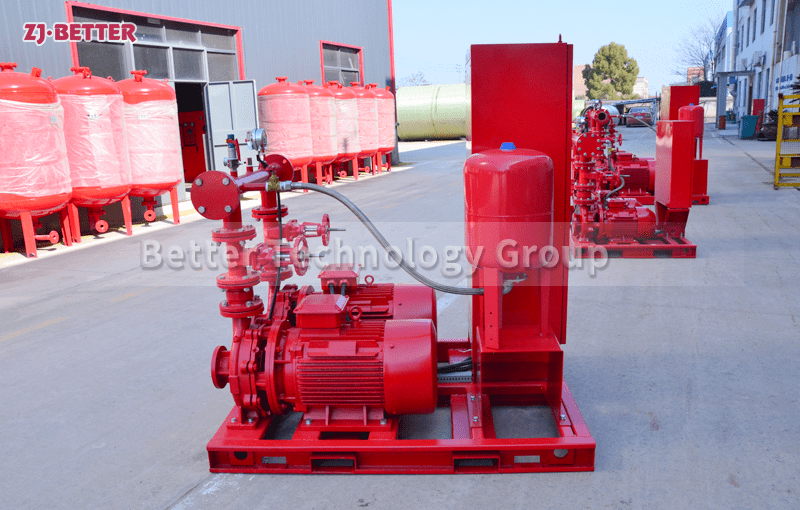

As a core piece of equipment in modern fire protection systems, the performance and reliability of electric fire pumps directly affect the fire safety level of the entire building or industrial site. With continuous technological advancements, electric fire pump systems have gradually upgraded from traditional manual control to intelligent and automated operation systems. The application of automatic monitoring systems in the field of fire safety has greatly improved the operating efficiency, stability, and safety of the equipment. The automatic monitoring system of an electric fire pump mainly consists of an electrical control cabinet, pressure sensors, flow detection devices, an alarm system, a remote monitoring module, and an emergency start-stop system. This system uses high-precision sensors to collect operating parameters such as pressure, flow, current, and voltage in real time. When the system detects a drop in water supply pressure or a fire hydrant network activation signal, it automatically starts the fire pump to pressurize the water supply, ensuring sufficient fire water supply in the early stages of a fire, thereby effectively controlling the spread of fire. Compared with traditional manual control methods, the automatic monitoring system can respond to fire alarm signals in a very short time, reducing safety hazards caused by human delays and ensuring the timeliness and reliability of the fire protection system. The control system of the electric fire pump adopts advanced PLC control technology, enabling multi-pump linkage, automatic switching, and intelligent adjustment functions. When the main pump fails, the system automatically switches to the standby pump to ensure uninterrupted water supply. This redundancy design significantly improves the safety of the fire protection system, making it particularly suitable for locations with extremely high safety requirements, such as hospitals, airports, subways, high-rise buildings, and petrochemical plants. The system is also equipped with multiple safety protection measures, including motor overload protection, short circuit protection, phase loss protection, and overheat alarms, ensuring stable and reliable operation over long periods. Its monitoring system can automatically adjust the pump’s start-stop status based on pipeline pressure, achieving energy-saving operation. When the pressure reaches the set upper limit, the system automatically stops operating; when the pressure drops to the set lower limit, it automatically starts again, forming an intelligent closed-loop control. This not only extends equipment life but also significantly reduces energy consumption, meeting the energy-saving and environmental protection requirements of modern industry. For higher-level management, the automatic monitoring system of electric fire pumps typically supports remote monitoring and data logging. Through a network communication module, managers can view key data such as pump operating status, pressure changes, and current curves in real time at the monitoring center. In case of abnormalities, such as insufficient water pressure, equipment failure, or electrical faults, the system will automatically alarm and record fault information for easy maintenance and analysis later. This design enables the fire protection system to be “visualized, traceable, and controllable,” significantly improving operational efficiency. One of the system’s core advantages is high reliability. Since fire protection equipment is on standby most of the time, reliable startup is crucial. The automatic monitoring system has a built-in periodic self-test program that periodically tests motors, valves, sensors, and control circuits to ensure all components are in optimal condition. The self-test process does not affect normal system operation; it is completed automatically in the background. This allows the fire pump to respond to commands within milliseconds and quickly begin operation in the event of a fire, ensuring uninterrupted water supply for firefighting. The structural design of the electric fire pump also fully considers the collaborative requirements of the automation system. The pump body is typically made of high-strength cast iron or stainless steel, offering excellent pressure and corrosion resistance, and is suitable for long-term high-intensity operation. The motor adopts a high-efficiency, energy-saving design, working in conjunction with the control system to achieve soft start and variable frequency speed regulation, resulting in more stable water pressure output and avoiding water hammer impacts during traditional pump startup. The system’s piping layout is scientifically optimized, ensuring smooth flow, reducing energy loss, and significantly improving overall efficiency. In terms of operational performance, electric fire pumps feature high head, large flow rate, and high stability, meeting the fire water needs of various types of buildings. They operate with low noise and vibration, making them particularly suitable for office buildings, hotels, shopping malls, and residential communities with high environmental requirements. Furthermore, the integration of an automatic monitoring system makes the entire operation more intelligent, precise, and safe. For example, when fluctuations in pipeline pressure are detected, the system automatically determines whether it is a peak water usage period or a fire alarm signal, adjusting the operating mode accordingly to avoid mechanical wear and energy waste caused by frequent start-stop cycles. The automatic monitoring system for electric fire pumps also supports data linkage with building fire alarm systems, building automation systems (BAS), and smart city fire protection platforms, enabling information sharing and centralized management. When a fire alarm signal is triggered, the monitoring system can automatically link sprinkler systems, alarm systems, smoke extraction systems, and other facilities to form a complete intelligent fire emergency response system. This integrated system design makes fire management more efficient, significantly improving overall emergency response capabilities. Regarding maintenance and management, the automatic monitoring system displays detailed operating parameters and historical data through an interface, allowing technicians to perform preventative maintenance based on system prompts, reducing the failure rate. The modular design of the system simplifies maintenance and replacement, reducing subsequent operation and maintenance costs. Some systems also support remote monitoring via mobile app, allowing managers to check equipment status at any time, further enhancing the convenience and security of operation and maintenance. Overall, the automatic monitoring system for electric fire pumps integrates automatic detection, intelligent control, energy-saving operation, and remote management, making it an indispensable core piece of equipment in modern fire protection systems. It not only plays a crucial role in improving fire response speed, reducing energy consumption, and enhancing equipment reliability, but also promotes the digitalization and intelligentization of fire protection equipment through the introduction of intelligent technologies. Whether from the perspective of safety, stability, economy, or management efficiency and technical level, automated electric fire pump systems represent the mainstream trend of contemporary fire protection equipment. In the future, with the further integration of IoT and AI technologies, the monitoring system for electric fire pumps will become more intelligent, precise, and efficient, providing safer and more reliable fire protection for various buildings and industrial facilities, laying a solid foundation for achieving the goal of “smart fire protection.”