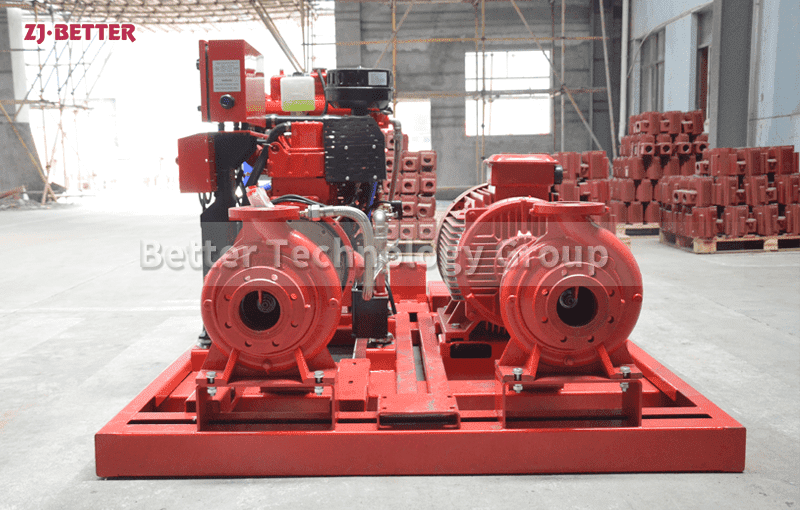

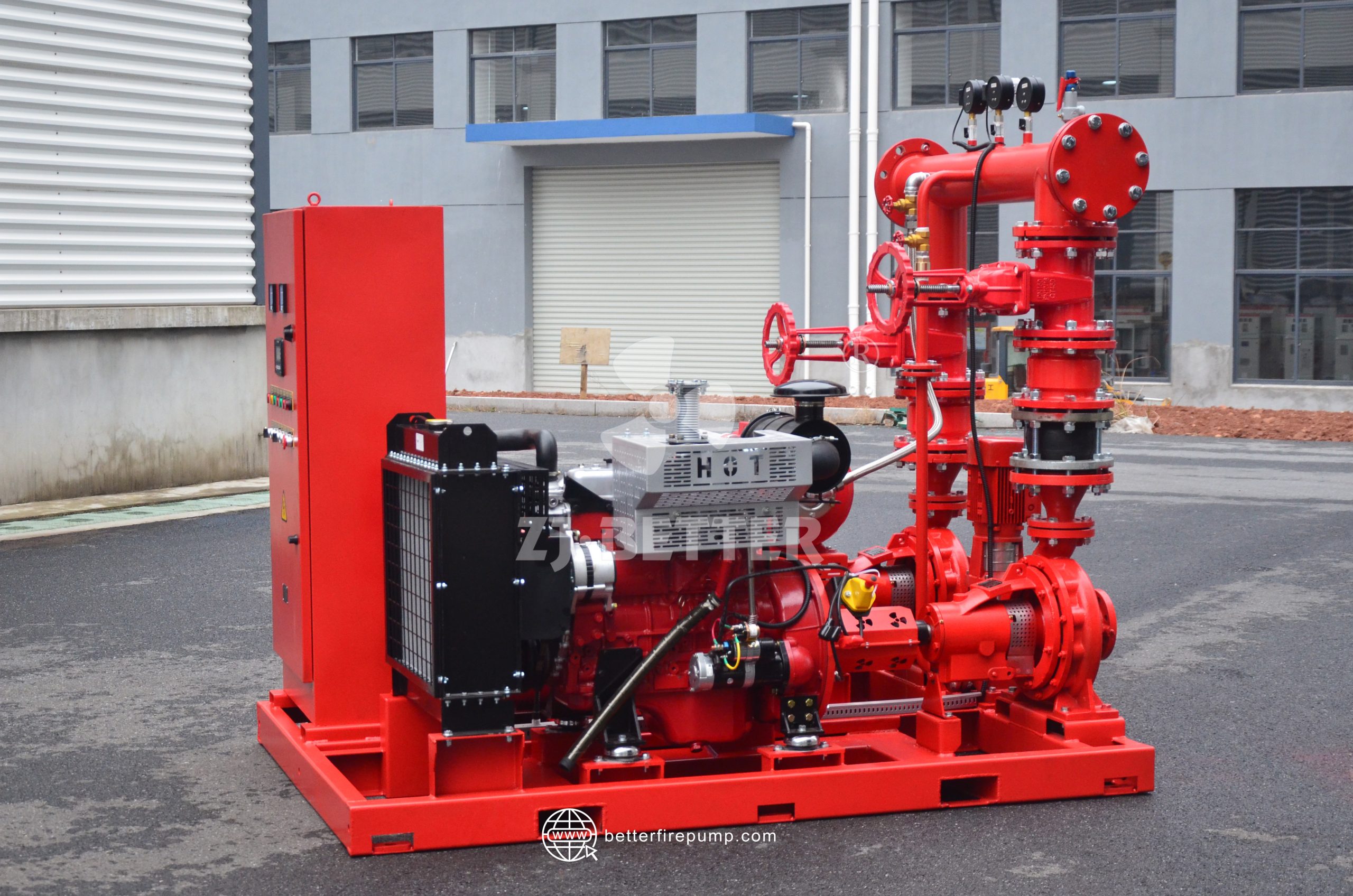

The diesel-powered integrated fire pump system is a critical piece of equipment in the fire protection industry for addressing challenges posed by extreme environments and high-risk locations. Its independence, high performance, and strong adaptability make it an indispensable core component for ensuring a reliable fire water supply. In various application scenarios such as urban buildings, high-risk industrial facilities, port chemical zones, oil and gas pipeline sites, unmanned stations, and power systems, the system must contend with real-world challenges such as sudden power outages, extreme temperature fluctuations, high air humidity, and uncertain fuel supply. traditional electric fire pumps often struggle to start properly or face water delivery issues. In contrast, diesel-driven integrated fire pump systems offer a true emergency solution for fire systems through their highly integrated structural design, self-sufficient energy systems, intelligent control modules, stable pressure output capabilities, and excellent maintenance convenience. These products integrate a diesel engine, high-efficiency centrifugal pump, pressure stabilization device, cooling system, fuel system, control cabinet, and a steel frame base, enabling them to be installed and used directly upon delivery without requiring additional user assembly. This significantly enhances on-site installation efficiency and overall system stability. The products are constructed using high-strength cast iron or stainless steel materials, offering exceptional corrosion resistance and high-pressure structural integrity, making them particularly suitable for coastal, arctic, or dusty environments. The diesel engine component utilizes top-tier domestic and international brands such as Cummins, Weichai, and Yuchai as the power core, ensuring stable output and fuel consumption control during prolonged continuous operation. It also complies with international and national fire safety standards such as NFPA 20 and GB 27898. The control system is equipped with an intelligent start-stop module, enabling functions such as scheduled inspections, self-diagnosis, fault lockout, and historical data storage. It supports remote connection to a platform and enables PLC logic-linked control, ensuring the fire pump system responds swiftly and delivers precise water supply during critical situations. The integrated structure’s key advantage lies in its compact footprint, clear pipe routing, and convenient installation and wiring. It is not only suitable for rapid deployment in new fire stations but also widely applied in renovation projects or temporary emergency areas, offering exceptional flexibility. Additionally, the system includes a pre-pressurized water tank and check valve, enabling rapid formation of a closed-loop water pressure during initial water supply, thereby reducing pump startup time, preventing dry running damage to the pump body, and significantly enhancing equipment reliability and service life. To address diverse operational requirements, the product offers multiple flow rate and head combination options, with a maximum flow rate exceeding 300 L/s and a maximum head exceeding 180 m, catering to diverse needs from high-rise buildings to long-distance water supply. In terms of maintenance, the product features a rational structure that facilitates disassembly and replacement of components. Both the diesel engine and pump sections are equipped with inspection windows, drain ports, and lubrication reminder devices, enabling quick maintenance and regular servicing even in remote or enclosed locations. The modular design allows users to replace components or modify configurations without disassembling the entire system, thereby reducing maintenance costs and system downtime. To further ensure operational safety, the product is equipped with multiple safety devices such as overspeed protection, temperature monitoring, and low oil level alarms, fully meeting stringent industrial-grade operational standards. As a professional fire pump manufacturer, ZJ-BETTER focuses on integrating international standards with local operating conditions in the technical development of this product, making the entire diesel-powered integrated fire pump system widely adopted and highly recognized globally. It has become the preferred fire protection solution for clients in industries such as petrochemicals, metallurgy, transportation, and energy. It is not merely a pump but a “emergency core” safeguarding lives and property in critical moments, ensuring stable water pressure, reliable water supply, and rapid startup when needed most, confidently addressing any sudden fire incidents or water crises.