Pressure Stabilization and Dual-Function Pump System: Enhancing Emergency Response Speed in Fire Protection

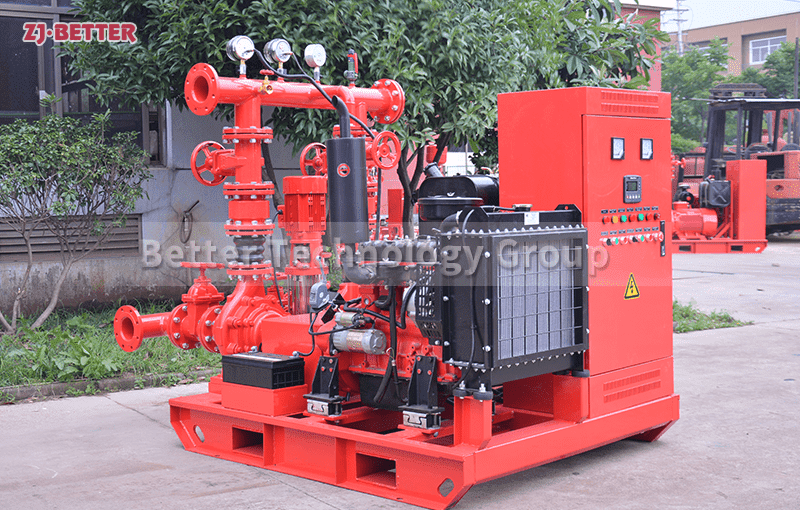

In modern fire protection systems, rapid response to fire incidents is crucial for safeguarding life and property. The Pressure Stabilization and Dual-Function Pump System integrates powerful pressure regulation with dual power sources to ensure that the fire protection system quickly responds and maintains a continuous, stable water supply during emergencies.

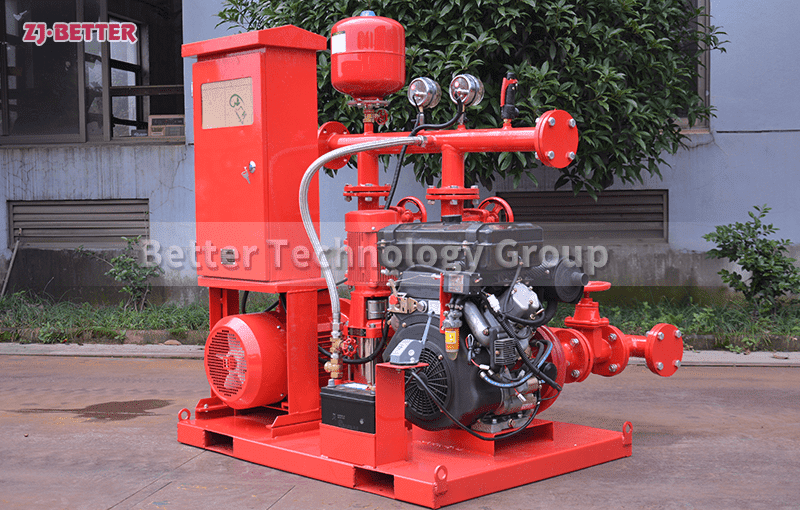

This pump system is designed with two power sources—an electric motor and a diesel engine. When the primary power source fails, the diesel engine automatically starts, ensuring uninterrupted operation of the fire protection system even during power outages. Its pressure stabilization system automatically adjusts pressure during operation, ensuring stable water flow for fire suppression and preventing water interruptions due to insufficient or fluctuating pressure, ultimately improving firefighting efficiency.

The intelligent control system further enhances the efficiency of the pump system, allowing users to monitor the system’s status in real-time through a touch panel. The system is easy to operate, and any malfunction is quickly detected and alarms are triggered, activating backup systems to effectively prevent emergency issues caused by system failure.

This pump unit is ideal for applications in high-rise buildings, industrial zones, storage facilities, and other locations with high reliability requirements for fire protection, ensuring that the fire pump can be immediately activated and continue to supply water in any emergency.

With a strong focus on the development and manufacturing of innovative fire pump systems, the company is committed to providing efficient and reliable fire pump equipment to the global market. With years of technological development and innovation, the diesel and electric fire pumps produced by the company have been widely used across various sectors, including industrial, commercial, and petrochemical industries. The compact design and robust adaptability make these pumps suitable for extreme environmental conditions, including high temperatures, high humidity, and harsh industrial environments.

The company prioritizes quality control and performance optimization, ensuring that every product undergoes rigorous testing and meets international fire safety standards. With intelligent control systems, pressure stabilization functions, and dual-drive modes, our products excel in emergency response capabilities, ensuring that fire protection systems can start up and operate quickly and reliably during a fire emergency.

In today’s global market, the company has provided fire pump solutions to various countries and regions, earning widespread recognition and trust from clients. With outstanding technology, a comprehensive service system, and efficient after-sales support, the company continues to provide the most valuable fire safety solutions to customers.