Anti-Corrosion Fire Pump for Marine Engineering and Salt Spray Environments

Corrosion-resistant fire pumps are high-performance firefighting equipment specifically designed for marine, chemical, and high-salt-spray environments. They possess excellent corrosion resistance, high efficiency, and long service life. Utilizing corrosion-resistant materials and an intelligent control system, they maintain a stable water supply even in harsh environments, ensuring reliable operation of the fire protection system. Suitable for coastal facilities, oil platforms, docks, and industrial plants, they provide safe and efficient fire protection for critical areas.

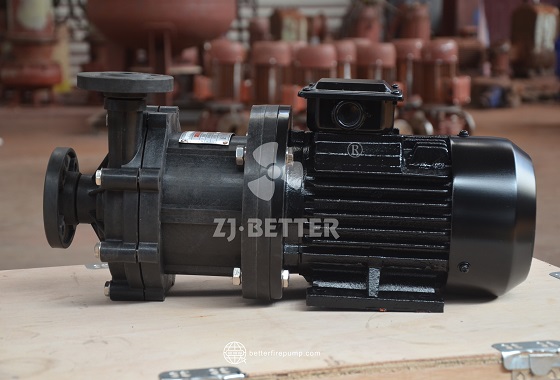

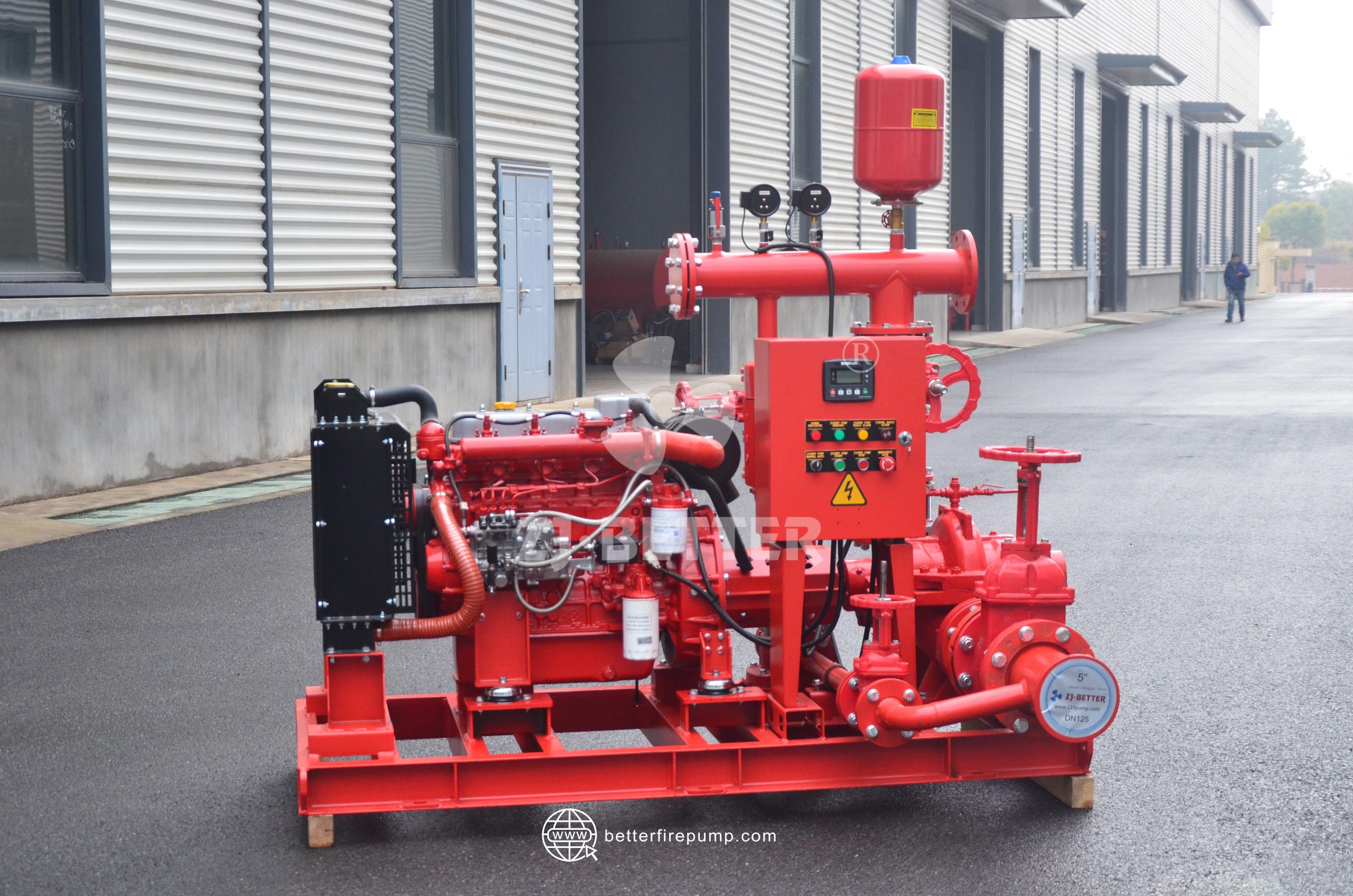

Corrosion-resistant fire pumps play a crucial role in modern fire protection systems, especially in marine engineering, coastal areas, ports, chemical plants, and fire prevention facilities in high-salt-spray environments. These pumps are designed to withstand extreme corrosive conditions, ensuring stable and efficient operation even in long-term high-humidity, high-salt, and highly corrosive gas or liquid environments. Constructed from high-grade corrosion-resistant materials, typically including engineering plastics, stainless steel, or special alloy components, they effectively resist the erosion of salt spray, acid and alkali solutions, and chemicals, ensuring reliable operation of the entire system in harsh environments. The pump body has a compact and scientifically designed structure, with the impeller and pump casing precisely optimized for fluid dynamics, resulting in higher hydraulic efficiency and lower energy consumption, maintaining stable flow and pressure output while transporting the medium. The greatest advantage of corrosion-resistant fire pumps lies in their excellent corrosion resistance. The air in marine engineering and salt-spray environments contains a large amount of chloride ions, which can severely corrode ordinary metals. Corrosion-resistant fire pumps effectively avoid this problem by using corrosion-resistant materials and surface protection processes. The pump’s sealing system employs a multi-layered protective structure, including a mechanical seal, double-layer sealing rings, and corrosion-resistant sealing materials, preventing liquid leakage and extending equipment lifespan. Even when immersed for extended periods in environments containing salt or chemical solutions, this pump maintains the integrity of its internal components, significantly reducing maintenance frequency and replacement costs. In terms of performance, the corrosion-resistant fire pump boasts high efficiency and stability. Its motor system features a high-efficiency, energy-saving design, equipped with heat-resistant insulation materials, maintaining a low temperature rise during prolonged continuous operation to prevent overheating damage. The impeller undergoes balancing testing and corrosion protection, ensuring smooth operation at high speeds with low noise, minimal vibration, and high energy conversion efficiency, guaranteeing stable outlet pressure and sufficient flow. Whether on offshore platforms, in shipyards, or in coastal power plants, the corrosion-resistant fire pump provides a continuous and reliable water supply, ensuring rapid response and powerful fire suppression water pressure in emergencies. The design of the corrosion-resistant fire pump also prioritizes ease of operation and maintenance. Its modular structure allows for flexible installation, enabling horizontal or vertical layouts depending on site conditions, and various connection methods for easy integration with existing piping systems. The control system supports intelligent operation, enabling automatic start/stop, pressure monitoring, and alarm linkage, ensuring timely shutdown for protection or switching to a backup system in case of pump malfunction. For special operating conditions, such as areas containing chemical gases or highly corrosive liquids, explosion-proof motors or fully enclosed protective covers can be configured to further enhance safety. Compared to traditional cast iron or ordinary steel fire pumps, corrosion-resistant fire pumps not only offer superior durability but also excellent operational economy. Due to their significant corrosion resistance, the equipment does not require frequent replacement of seals or major structural components, thus reducing downtime and maintenance costs. Simultaneously, its efficient hydraulic design effectively reduces energy consumption, significantly saving energy costs over long-term operation. This energy-saving characteristic is particularly important for offshore facilities requiring 24-hour uninterrupted monitoring and backup water supply, ensuring sufficient system pressure is maintained even under limited energy supply conditions. Advances in materials technology have further improved the performance of corrosion-resistant fire pumps. Modern corrosion-resistant pumps widely utilize glass fiber reinforced plastics, fluoroplastics, stainless steel alloys, or composite coating technologies, giving the pump body both lightweight and high strength. These materials not only withstand salt spray corrosion but also resist the erosion of some acidic and alkaline chemical media, making them suitable for stable application in fire protection systems in chemical, pharmaceutical, papermaking, and food processing industries. Some products also employ an internal anti-corrosion lining process, further enhancing their corrosion resistance by spraying a high-polymer protective layer onto the flow channel surface, while reducing fluid friction loss and improving overall efficiency. Corrosion-resistant fire pumps also demonstrate strong adaptability in system compatibility. They can be flexibly combined with electric motors, diesel engines, or electrical control cabinets to form electric or diesel corrosion-resistant fire pump sets to meet the fire protection needs of different scenarios. For projects requiring emergency backup, an automatic control system can be equipped to achieve automatic switching between main and standby pumps, ensuring stable operation of the fire protection system under any circumstances. Their standardized interface design facilitates integration with sprinkler systems, fire hydrant systems, or foam extinguishing systems, meeting the fire protection requirements of various buildings or equipment. Corrosion-resistant fire pumps not only possess leading advantages in performance and structural design but also make significant contributions to environmental protection and sustainability. Due to the use of durable anti-corrosion materials, their lifespan is longer, effectively reducing resource waste and replacement frequency. Meanwhile, this pump operates with low noise and minimal vibration, minimizing its environmental impact, making it ideal for use in residential areas, commercial buildings, or ship cabins. Many models also meet international fire protection standards and energy-saving certification requirements, ensuring their global versatility and reliability. With the continuous development of coastal cities and offshore engineering projects worldwide, the demand for corrosion-resistant fire protection systems is constantly increasing. As core equipment, corrosion-resistant fire pumps must continuously provide stable water pressure in long-term high-salt, high-humidity, and high-temperature environments. Their excellent structural design, superior protective performance, and intelligent control technology make them an irreplaceable and crucial piece of equipment in various fire protection projects. Whether in ocean-going vessels, port storage facilities, oil platforms, coastal power plants, or chemical tank farms, they provide safe, stable, and efficient fire-fighting water supply, offering a solid defense for people’s lives and property. With its reliable performance, superior durability, energy-saving operating characteristics, and wide adaptability, the corrosion-resistant fire pump has become the preferred solution for modern fire protection systems to cope with extreme environments. It not only represents the advancement of fire pump manufacturing processes and material technology but also serves as a significant marker of the intelligent, long-life, and green energy-saving direction of fire safety equipment.