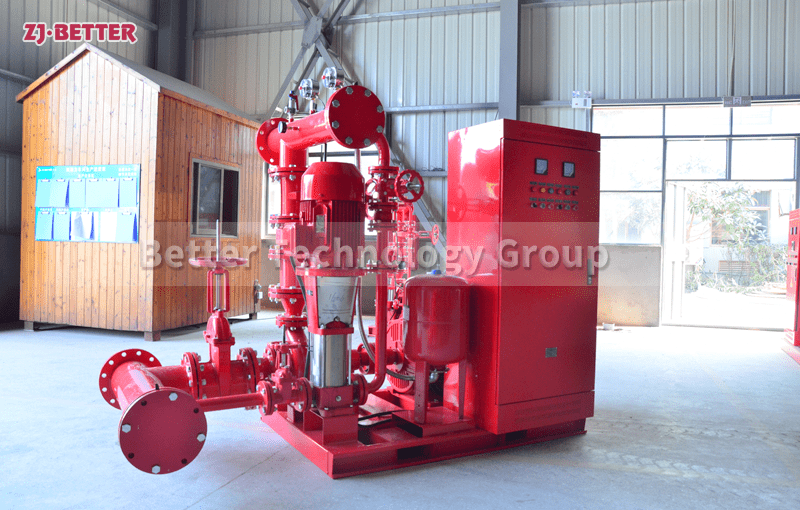

Efficient and Reliable Box-type Non-Negative Pressure Water Supply Equipment

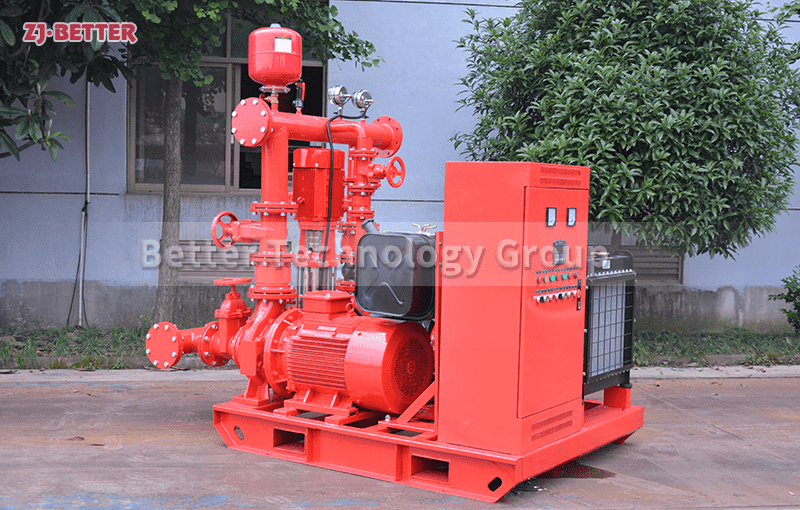

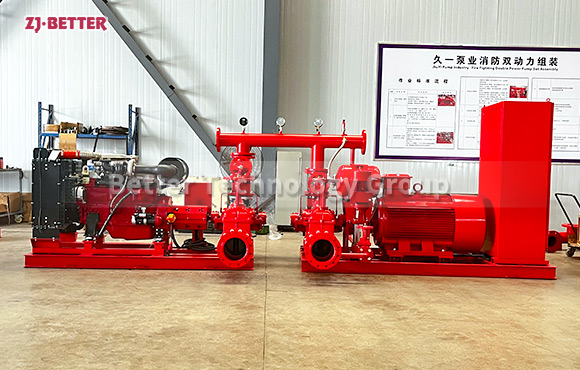

Our highly acclaimed Box-type Non-Negative Pressure Water Supply Equipment is the savior for your hotels, hospitals, schools, and more! Not only does it provide stable water flow and pressure, but it also guarantees fresh water quality! Suitable for life water supply systems in high-rise buildings, residential communities, and large-scale architectural complexes, bid farewell to water shortage worries! The Box-type Non-Negative Pressure Water Supply Equipment features an advanced automatic control system that instantly starts the water pump when demand increases, providing you with a continuous and stable water flow. And when demand decreases, the pump intelligently stops, avoiding energy waste! The compact box-type structure makes installation and maintenance a breeze! Whether it’s solving water supply issues in low-pressure areas or addressing the needs of places like hotels, hospitals, and schools where water cannot be shut off but face insufficient tap water pressure, our Box-type Non-Negative Pressure Water Supply Equipment offers the perfect solution!

- Superior Water Pressure: Our Box-typeNon-Negative pressure water supply equipment ensures a consistent and powerful water pressure, addressing the problem of low water pressure in high-rise buildings, residential communities, and large-scale architectural complexes. Enjoy a satisfying and robust water flow throughout your premises.

- Fresh Water Quality Guarantee: In addition to boosting water pressure, our equipment also prioritizes water quality. It ensures the freshness and cleanliness of the supplied water, making it suitable for hotels, hospitals, schools, and other establishments where water quality is of utmost importance.

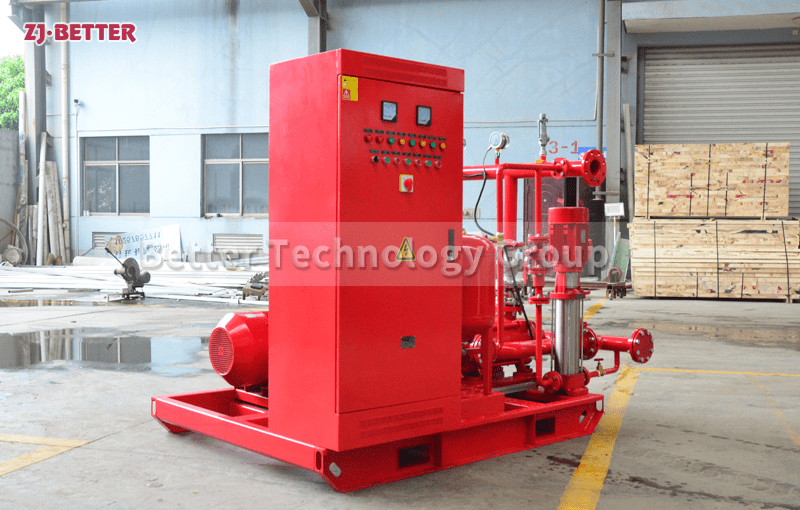

- Automatic Control System: Our equipment is equipped with an advanced automatic control system. It intelligently monitors water demand and activates the water pump promptly when required. This ensures a seamless and uninterrupted water supply, eliminating the inconvenience caused by water shortages.

- Compact and Easy Installation: The box-type design of our negative pressure water supply equipment offers a compact and space-saving solution. Its installation is straightforward, and the equipment is designed for easy maintenance, making it convenient for installation teams and reducing downtime during maintenance.

- Versatile Applications: Our equipment is highly versatile and suitable for various settings, including high-rise buildings, residential communities, and large-scale architectural complexes. It caters to the water supply needs of hotels, hospitals, schools, and other facilities where continuous water supply is crucial, even in situations where tap water pressure is insufficient.

- Energy Efficiency: The automatic control system ensures that the water pump operates only when required, effectively saving energy and reducing operational costs. This eco-friendly feature contributes to sustainable and cost-effective water management.

Choose our Box-type Non-Negative pressure water supply equipment to enjoy the benefits of superior water pressure, guaranteed water quality, automatic operation, easy installation, and versatile applications. Experience reliable and efficient water supply for your premises, ensuring the comfort and convenience of your residents, guests, or occupants.